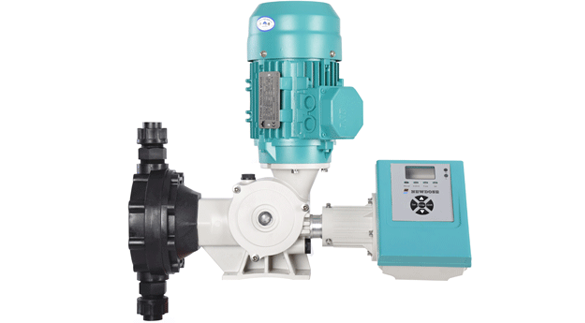

Detergent Dosing Pump

We, Ark Electric & Mechanical Co., Ltd., specializes in providing NEWDOSE detergent dosing pump. If the backwash water contains A13+ produced by adding flocculants, it is easy to generate a large amount of milky precipitation, so it is not suitable for backwashing. Since the NaCL0 solution has a better sterilization effect under acidic conditions, it is recommended that when designing the NaCL0 detergent dosing system, there are three ways. First: add ammonia in water with 2 solution tanks and 4 metering pumps, including local control cabinet. Second: add hydrazine in water with 2 solution tanks and 4 metering pumps, including local control cabinet. Third: add phosphate in boiler water with 2 solution tanks and 5 metering pumps. The contents are civil construction parts such as the water inlet lifting pump room, the chlorination dosing room and the water pump room. As for the brand for the mentioned-above metering pump, Ark Electric & Mechanical Co., Ltd. is a good choice. Although both stroke length and frequency can be used as adjustment variables, in engineering applications, the stroke length is generally regarded as a coarse adjustment variable, and the stroke frequency is a fine adjustment variable, which adjusts the stroke length to a certain value, and then achieves fine adjustment by changing its frequency, increasing Adjustment flexibility. In relatively simple applications, the stroke length can also be manually set, only by using the stroke frequency as the adjustment variable, thus simplifying the system configuration.

There are many types of metering dosing pump. Different types of metering pumps have different technical parameters and performance. Welcome all the customers to inquire for more product information about detergent metering pumps. We will provide you with a new solution for detergent metering pumps.

Importance Of Detergent Metering Pump

The motor is an important part of the detergent metering pump as a “heart”. Once a problem occurs, it will affect the use of the equipment. During the operation of the detergent metering pump, the most common problem with the motor is that the temperature is too high.

Why The Motor Running Temperature Of The Detergent Metering Pump Is Too High

Many factors may cause the motor temperature of the detergent metering pump to be too high.

The detergent metering pumps of the NEWDOSE brand have passed strict testing and quality control, and are favored by many clients. Welcome to discuss cooperation with us!

Now the price of diaphragm chemical dosing pumpis affordable, if you want to buy ammonia dosing pumpand boiler dosing pump, please leave us a message.

在线联系供应商

Other supplier products

| Motor Driven Diaphragm Pump | Motor driven metering pumphas to be strong and stable. Every series of NEWDOSE motor-driven dosing pumps offer a range of different models, with ma... | |

| High Pressure Dosing Pump | High pressure dosing pumps are useful in many occasions of technology, and high pressure and mass flow are the typical features of it. However, hig... | |

| Sulfuric Acid Metering Pump | Sulfuric acid is a kind of active binary inorganic strong acid, which can react with most metals. High-concentration sulfuric acid has strong water... | |

| Ecodose Type Mechanical Motor Dosing Pump | EcodoseType Mechanical Motor Functional Motor Dosing Pump AssemblyCharacteristics Ark Electric & Mechanical Co., Ltd.(ARK LTD) is a ... | |

| High Pressure Dosing Pump | High pressure dosing pumpare useful in many occasions of technology, and high pressure and mass flow are the typical features of it. However, high ... |

Same products

| Zbk03 Series Roots Vacuum Pump/Roots Pump | 卖方: Greentech International (Zhangqiu) Co., Ltd | ZBK series roots vacuum pump is a kind of coarse vacuum acquisition of equipment, it is widely us... | |

| "Brand Assurance Globe valve GR2-0-KB-G5/30X48 for power generation | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Brand Assurance Globe valve GR2-0-KB-G5/30X48 for power generation YOYIK is a large number of st... | |

| Wear Resistance Electric stop valve NKJ961Y-16C for thermal power plant | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Wear Resistance Electric stop valve NKJ961Y-16C for thermal power plant YOYIK professional produ... | |

| Brand Assurance Stop valve J61Y-600CL for power generation | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Brand Assurance Stop valve J61Y-600CL for power generation YOYIK is a large number of steam turb... | |

| JWSP-1 Oil Sampling Pumps | 卖方: Shenzhen Joinwe Smart Co.,Ltd | JWSP-1 Oil Sampling Pumpis made of imported PA material, 303 stainless steel and 6061 aluminum al... |