Carbon Seal

Carbon shaft sealhas a long history. Graphite is an isoform of element carbon. In 1971, the United States studied the successful flexible graphite sealing material, which solved the leakage of atomic energy valve. After deep processing, the flexible graphite becomes an excellent sealing material, which are made into various carbon mechanical seals with the effect of sealing components. These carbon mechanical seals are used in chemical, petroleum, electric power industries such as high temperature fluid seal.

Because the flexible graphite is formed by the expansion of expanded graphite after high temperature, the amount of intercalating agent remaining in the flexible graphite is very small, but not completely, so the existence and composition of the intercalation agent have a great influence on the quality and performance of the product.

Selection of Carbon Seal Material

The original inventor used concentrated sulfuric acid as oxidant and intercalating agent. However, after being applied to the seal of a metal component, a small amount of sulfur remaining in the flexible graphite was found to corrode the contact metal after long term use. In view of this point, some domestic scholars have tried to improve it, such as Song Kemin who choosed acetic acid and organic acid instead of sulfuric acid. acid, slow in nitric acid, and lower the temperature to room temperature, made from a mixture of nitric acid and acetic acid. By using the mixture of nitric acid and acetic acid as the inserting agent, the sulfur free expanded graphite was prepared with potassium permanganate as oxidant, and acetic acid was slowly added to nitric acid. The temperature is reduced to room temperature, and the mixture of nitric acid and acetic acid is made. Then the natural flake graphite and potassium permanganate are added to this mixture. Under constant stirring, the temperature is 30 C. After reaction 40min, the water is washed to neutral and dried at 50~60 C, and the expanded graphite is made after high temperature expansion. This method achieves no vulcanization under the condition that the product can reach a certain volume of expansion, so as to achieve a relatively stable nature of the sealing material.

Specification of Carbon Ring Seal

Sealconcan produce different carbon ring seals according to different customers’ requirement.

|

model |

M190T |

M106K |

M180K |

M106D |

M160C |

M160B |

|

material |

pure graphite |

furan resin |

furan resin |

antimony carbon |

copper alloy |

Babbitt alloy |

|

density (g/cm3) |

||||||

|

Fractural strength |

100 |

65 |

80 |

65 |

80 |

65 |

|

(MPa) |

||||||

|

compressive strength (MPa) |

250 |

230 |

240 |

200 |

250 |

160 |

|

Shaw hardness |

92 |

90 |

90 |

80 |

75 |

60 |

|

porosity (%) |

2 |

8 |

||||

|

Coefficient of heat |

6 |

|||||

|

expansion (1/℃) |

||||||

|

temperature (℃) |

600 |

210 |

210 |

350 |

350 |

200 |

|

medium |

concentration% |

pure graphite |

furan resin |

antimony |

copper alloy |

Babbitt alloy |

|

hydrochloric acid |

36 |

+ |

0 |

- |

- |

- |

|

sulfuric acid |

50 |

+ |

0 |

- |

- |

- |

|

sulfuric acid |

98 |

+ |

+ |

- |

- |

- |

|

nitric acid |

50 |

+ |

0 |

- |

- |

- |

|

nitric acid |

strong |

- |

- |

- |

- |

|

|

hydrofluoric acid |

40 |

+ |

0 |

- |

- |

- |

|

phosphoric acid |

85 |

+ |

+ |

- |

- |

- |

|

chromic acid |

10 |

+ |

0 |

- |

- |

- |

|

acetic acid |

36 |

+ |

0 |

- |

- |

- |

|

sodium hydroxide |

50 |

+ |

+ |

- |

- |

+ |

|

potassium hydroxide |

50 |

+ |

0 |

- |

- |

+ |

|

sea water |

+ |

+ |

+ |

+ |

+ |

|

|

benzene |

100 |

+ |

0 |

+ |

+ |

- |

|

ammonia |

10 |

+ |

+ |

+ |

+ |

- |

|

acetone |

100 |

+ |

+ |

+ |

0 |

+ |

|

carbamide |

+ |

+ |

+ |

0 |

- |

|

|

carbon tetrachloride |

+ |

+ |

+ |

+ |

+ |

|

|

oil |

+ |

+ |

+ |

+ |

+ |

|

|

gasoline |

+ |

+ |

+ |

+ |

+ |

+ stable - unstable 0 middle (between stable and unstable)

As a carbon seal ring manufacturer, we will offer more types of hydrocarbon pump mechanical sealfor customers, if you have needs, please contact us.

在线联系供应商

Other supplier products

| MECHANICAL SEALS FOR PUMP | Mechanical seal for pump is a kind of dynamic seal assembly, which is widely used on the rotating shaft. It is also known as the end seal. Consisti... | |

| Double Cartridge Mechanical Seals | Cartridge mechanical seal is the rotary ring, stationary ring, spring, auxiliary seal, bushings, glands, Gasket and static seal, total 7 components... | |

| Double Cartridge Seals D13 | Replacement for: John crane SL Agitators Features: Pulp and paper plant Sulzer APP pumps Performance Capabilities of Double CartridgeSeals D... | |

| MECHANICAL SEALS FOR PUMP | Mechanical seal for pump is a kind of dynamic seal assembly, which is widely used on the rotating shaft. It is also known as the end seal. Consisti... | |

| Different Types of Water Pump Seals | Elastomer Rubber Bellow Mechanical Seals Developed with rubber bellow, this type of seal is widely used for water, oil and other light duties appli... |

Same products

| Quick-response Mechanical seal M74N-140 for power generation | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Quick-response Mechanical seal M74N-140 for power generation Is YOYIK for the use of turbine uni... | |

| Oil Seal 118*160*13 for Truck Auto Part Shaft NBR KDIK oil seal factory | 卖方: Xingtai Honglei Seal Manufacturing Co., Ltd | Hot sale various high quality Truck oil seal from Chinaleading manufacturer. Our products are eff... | |

| Bh1941g Engine Timing Cover Seal Engine Camshaft Oil Seal | 卖方: Xingtai Honglei Seal Manufacturing Co., Ltd | A Suzuki oil sealis a mechanical seal used to seal the gaps between the rotating shaft and the st... | |

| Transmission Oil Seal Bh4371e Tb 35*50*9.5 OEM for Toyota | 卖方: Xingtai Honglei Seal Manufacturing Co., Ltd | Automotive oil sealsplay critical roles in different types of four wheeler vehicles. They are pri... | |

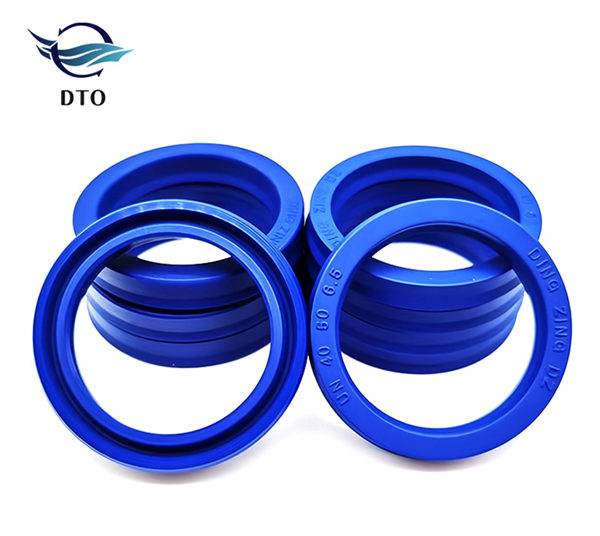

| UN Oil Seal | 卖方: Xingtai Dingtong Rubber and Plastic Products Co., Ltd | A pliable, non-metallic PU ringis ingeniously nestled within a precision-machined groove or seaml... |