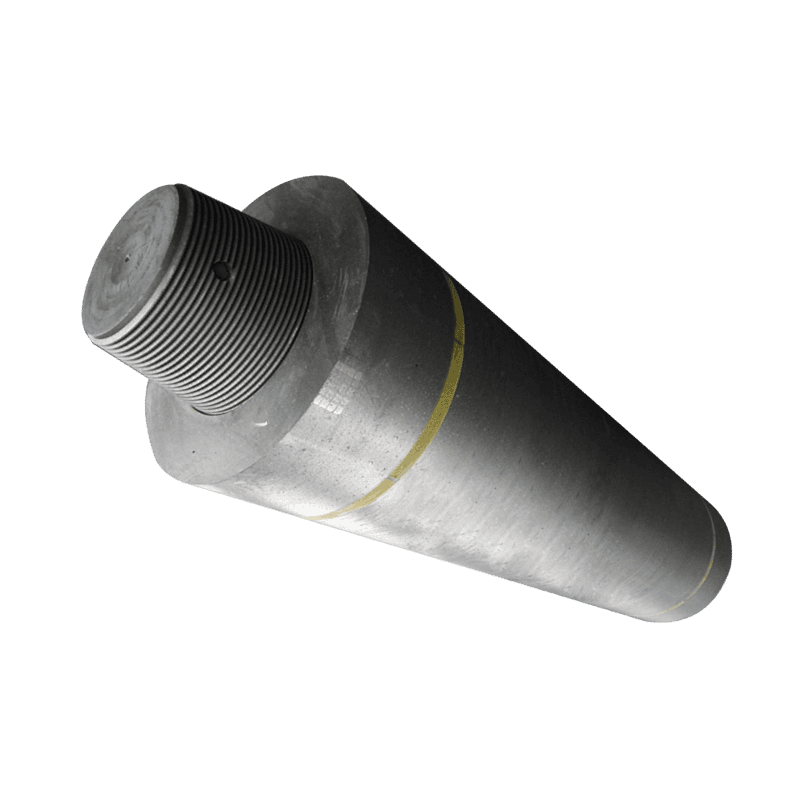

Graphite electrode φ300

Performance characteristics of ultra-high power graphite electrode in 300 arc furnace

Our products are characterized by high strength, good electrical conductivity, good thermal shock resistance and low consumption, and are widely used in metallurgical, chemical and mechanical industries. 50 % of the products are sold well in 30 provinces, cities and autonomous regions in China, and 50 % are exported to more than 30 countries and regions including Southeast Asia, Japan and South Korea, Europe, the Americas, and Africa.

Technical parameters of ultra-high power graphite electrode in 300 arc furnace

Specification for the Use of Ultra-High Power Graphite Electrodes in 300 Electric Arc Furnace

Points to note for the use of graphite electrodes:

1, wet graphite electrode, dry before use.

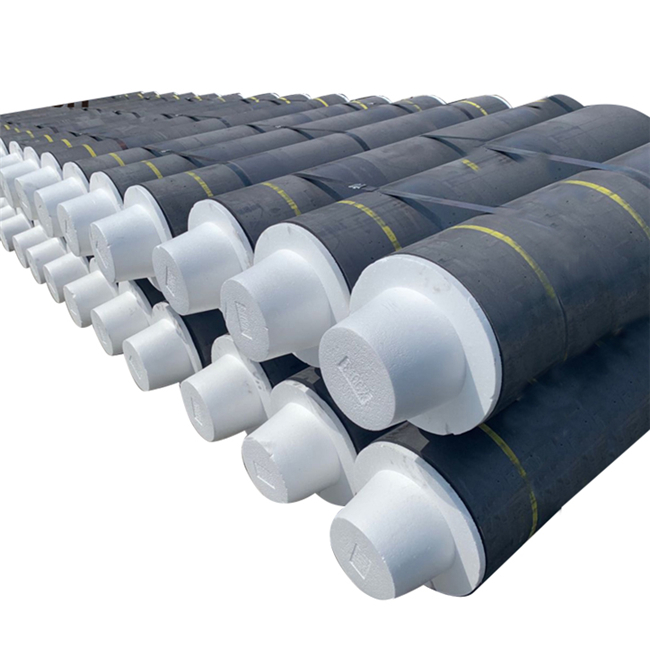

2, remove the foam protective cap on the spare graphite electrode hole, check whether the inner thread of the electrode hole is complete.

3, clean up spare graphite electrode surface and hole thread with compressed air without oil and water; Avoid cleaning sand cloth with steel or metal brushes.

4, carefully rotating the connector into the electrode hole at one end of the backup graphite electrode(it is not recommended to load the connector directly into the electrode removed from the furnace), not to collide threads.

5, the electrode hanging equipment(recommended graphite hanging equipment) into the electrode hole at the other end of the backup electrode.

6, when lifting the electrode, loosen the soft material to the bottom of the end of the standby electrode connector to prevent the ground from hitting the connector; Lift the pendant ring with a hook, and the lifting electrode must be stable to prevent the electrode from loosening from the B end or colliding with other fixing devices.

7, hanging the spare electrode to the top of the electrode to be connected, pointing at the electrode hole and slowly falling; Rotate the backup electrode so that the spiral hook rotates with the electrode to drop; When the two electric extremes are 10-20mm apart, the exposed parts of the two ends and joints of the electrode are cleaned again with compressed air; When the electrode is finally completely decentralized, it must not be too violent. Otherwise, due to violent collisions, the electrode holes and joints will be damaged.

在线联系供应商

Other supplier products

| UHP graphite electrode 450 | 石墨电极主要应用于冶金行业和电石、磷化工企业,如钢铁冶炼、工业硅、黄磷、铁合金、钛渣、棕刚玉等矿热炉熔炼生产。 大型石墨电极的典型性能。 直径:350mm-700mm 长度:1850毫米至2400毫米 每吨2400美元-2800美元 包装:木制 注意: 1.焊条应存放在清洁干燥的地方,避免振动... | |

| 石墨电极300 | 300电弧炉超高功率石墨电极的性能特点 我们的产品具有高强度、良好的导电性、良好的抗热震性和低消耗等特点,广泛应用于冶金、化工和机械行业。50%的产品畅销中国30个省市自治区,50%出口东南亚、日韩、欧洲、美洲、非洲等30多个国家和地区。 300电弧炉超高功率石墨电极技术参数 300电弧炉中超... | |

| Calcined Petroleum coke | 煅烧石油焦 1.主要用于电炉炼钢、筛分水、 2.用于提高炼钢和球墨铸铁的碳含量 3、高碳、低硫,对提高含碳量效果稳定 4.用于电炉炼钢和铸铁,提高含碳量 5.生产铸件时,增加废钢用量,减少废铁。标准出口包装,或客户要求 1,1吨大袋,18吨/20'集装箱 2、散装集装箱,20-21吨/20'... | |

| 石墨阳极 | 我们工厂生产石墨阳极,具有耐高温、导电导热性能良好,易机械加工,化学稳定性好,耐酸碱腐蚀,灰份低,用于电解水溶液,制取氯,苛性纳,电解食盐溶液制取碱;或用于电镀各种金属非金属载体,例如应用石墨阳极板可作为电解食盐溶液制取烧碱的导电阳极。也可用于化工,电子,纺织行业的污水处理 | |

| UHP graphite electrode 450 | 石墨电极主要应用于冶金行业和电石、磷化工企业,如钢铁冶炼、工业硅、黄磷、铁合金、钛渣、棕刚玉等矿热炉熔炼生产。 大型石墨电极的典型性能。 直径:350mm-700mm 长度:1850毫米至2400毫米 每吨2400美元-2800美元 包装:木制 注意: 1.焊条应存放在清洁干燥的地方,避免振动... |

Same products

| Impregnated Graphite Electrode | 卖方: Zhongsheng Carbon Technology Co., Ltd | ZSCGraphite electrodeare manufactured with high quality raw materials including petroleum cokes,n... | |

| Graphite Heating Rod | 卖方: Zhongsheng Carbon Technology Co., Ltd | Graphite Heating Rodis Applied for industrial furnaces as structural or heating parts, like gra... | |

| Graphite Electrode Scraps | 卖方: Zhongsheng Carbon Technology Co., Ltd | The graphite scraphas different definitions in different materials. Some materials and literature... | |

| HP Graphite Electrodes | 卖方: Zhongsheng Carbon Technology Co., Ltd | Graphite electrode are manufacturedwith high quality raw materials including petroleum cokes, nee... | |

| UHP Graphite Electrodes | 卖方: Zhongsheng Carbon Technology Co., Ltd | Graphite electrodeare manufactured with high quality raw materials including petroleum cokes, nee... |