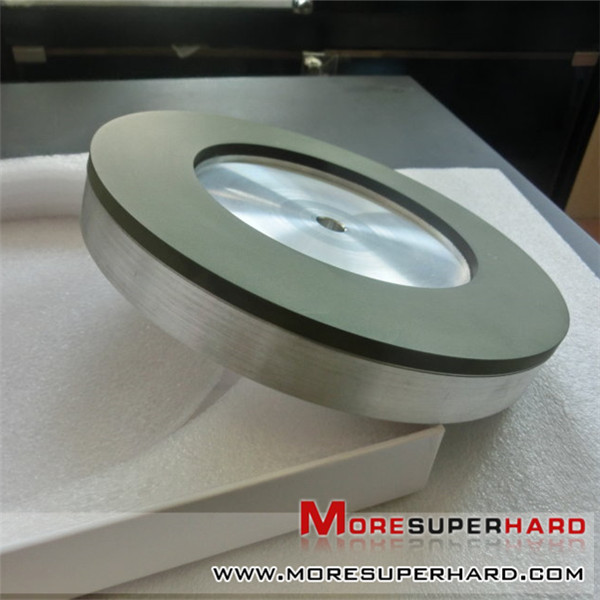

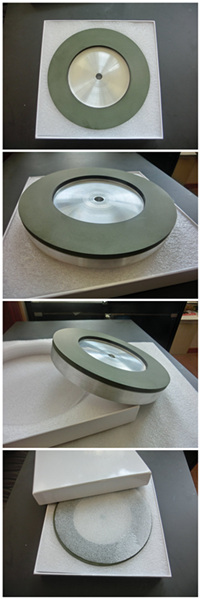

Resin Bond Diamond Grinding Discs/Laps For Gemstone

Description of resin bond diamond grinding disc/laps :

Instructions and maintenance for the resin bond lap: To get the best results, it is recommend

to first cut the stoneona cutting disc of 600 or 1200 mesh. Polishing is acomplished with a

constant drip of water by moving the stoneacrossall the area of the lap, to obtain a brilliant

flat surface. It is important to move the stone across the entire surface of thelap in order to

maintain a smooth and flat polishing surface.

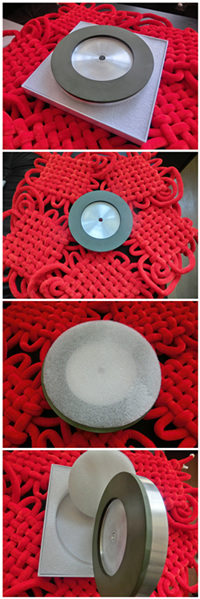

Idealforemeraldsoranyotherstonesthatmaybeheatsenstive.Effectiveforanykindsof

gemsexceptcorundum.Worksforstonesinthe1-2ct.sizerange.

The polishing powder is impregnated into the resin bond lap eliminating the need for any

additional agents. All that is added is water. This long lasting lap with a polishing layer of 6mm,

only requires dressing from time to time. Recommended operating speed is up to 1500 RPM.

When a light dressing is needed, a fine carborundum bar can be used to remove any ripples and

to restore a perfect flat surface. Plenty of water is required while dressing.

Application of resin bond diamond grinding discs/laps :

diamond millstone is mainly used for glass polishing and crystal polishing, likegemstone, quartz

glass, agate etc .Resin bond diamond grinding discs are widely used for fine face grinidng in

various industries.

Main features of resin bond diamond grinding disc/laps:

Specification of resin bond diamond grinding discs/laps:

Diameter:6″, 8″

Grit:60#, 80#, 100#, 180#, 260#, 360#, 600#, 1,200#, 3,000#

Configuration:without backing plates, with backing plates

在线联系供应商

Other supplier products

| Diamond Bruting Wheel | Description of Diamond Bruting Wheel: Vitrified Diamond bruting wheel is popular used in natural diamond bruting, grinding and polishing; it can a... | |

| CBN Wheel For Camshaft Grinding | Vitrified bond CBN Grinding Wheel is suitable for high-efficient heavy grinding of camshaft of automobile parts.The wheel speed is 80m/s-160m/s,Des... | |

| CBN Grinding Wheel For Crankshaft | Descriptionof CBN grinding wheel for crankshaft: CBN Grinding Wheel For Crankshaft can equip with various high precision NC Crankshaft Grinding Ma... | |

| Universal Crankshaft Grinding Wheel | Features of universal crankshaft grinding wheel: Crankshaft grinding wheel can be classified into parallel shape, single groove shape, double groo... | |

| Metal Bond Diamond Cup Wheel | Full segment wheel ,Internal segment wheel 、Continuous wheelaremetal bond diamond cup glass wheel. They are mainly used for glass edge grinding. Me... |