CNC ENGINEERING SERVICES

CNC Numerical Control milling machine in the CNC engineering servicesis controlled by digitizing signals with an electronic meter.

Numerical control milling machine is a kind of automatic machining equipment developed on the basis of general milling machine. Both of them have the same processing technology and similar structure. Numerical control milling machine is divided into two categories: no - strip and strip. CNC milling machine with cutter library is also known as machining center.

Functional features of CNC engineering services

In addition to the characteristics of ordinary milling machine, CNC milling also has the following characteristics:

CNC engineering services are with good adaptability and flexibility of parts processing. It is able to process parts with complex contour shape or difficult to control size, such as mold parts and shell parts;

CNC engineering services can process parts that cannot be processed or difficult to be processed by ordinary machine tools, such as complex curved parts described by mathematical models and three-dimensional curved parts;

CNC engineering services are able to process parts that need to be processed in multiple processes after the first clamping and positioning;

CNC engineering services have high machining accuracy, stable and reliable machining quality. The pulse equivalent of the numerical control device is generally 0.001mm, and the high-precision numerical control system can reach 0.1μm. In addition, the numerical control machining also avoids the operating error of operators.

CNC engineering services' high degree of production automation can reduce the labor intensity of operators. It is beneficial to the automation of production management.

CNC engineering services have high production efficiency. Generally, the CNC milling machine does not need to use special process equipment such as special fixture. When the workpiece is replaced, workers need only the machining procedure, clamping tools and tool data stored in the numerical control device. The production cycle can be shortened at a large extent. Secondly, the numerical control milling machine has the function of milling machine, boring machine and drilling machine. The process is highly concentrated and the production efficiency is greatly improved. In addition, the spindle speed and feed speed of the CNC milling machine are infinitely variable, so it is helpful to select the optimal cutting amount.

Processing characteristics of CNC engineering services

If the processing position is frame plane and not in the same equal altitude, point position - straight line system CNC milling machine is the best choice. If the machining position is a curved contour, the system of two-coordinate linkage and three-coordinate linkage should be selected according to the geometric shape of the curved surface. According to the requirements of parts processing, staff can add a numerical control dividing head or a numerical control rotary table on the basis of the general numerical control milling machine. At this time the machine tool system is the four coordinates numerical control system, which can process the spiral groove, the blade part and so on.

Size

The CNC milling machine with lifting table of smaller specification, whose table width is less than 400mm, is most suitable for the processing of small and medium parts and the contour milling of complex surface. Larger milling machines, such as gantry milling machines, have workstations of 500-600mm or more and can be used to process large and complex parts.

Precision

CNC engineering services have developed well in our country. The precision standard of CNC milling machine has been established in our country. What’s more, CNC vertical milling machine and lifting table milling machine have professional standards. According to the standard, the positioning accuracy of the linear motion coordinate is 0.04/300mm, the repeated positioning accuracy is 0.025mm, and the milling circle precision is 0.035mm. In fact, the machine tool factory precision has a considerable amount of storage, compared to the national standard tolerance value of about 20% compression. Therefore, from the point of precision selection, the general CNC milling machine can meet the processing needs of most parts. For the parts with high precision, the precision CNC milling machine should be considered.

Batch

For bulk parts processing, users can use a special milling machine. If the parts are manufactured in small and medium batches and are often remanufactured periodically, then a CNC milling machine is appropriate. Because the tools and programs used in the first production can be stored and reused. In the long run, it is inevitable that automatic milling machines will replace regular ones, reducing the labor force and increasing productivity.

CNC MACHINING PARTS

Together with 20 years of experience in the manufacturer of machining parts Ningbo Hewchois the professional of finished parts and components.

As the cnc machine parts suppliers, we can be your reliable partner for precision turned parts china, milled parts, machined parts, cold forged parts, metal stamped parts, special screws, threaded parts or any parts according to drawings, made of aluminum, brass, carbon steel, stainless steel or alloy steel.

在线联系供应商

Other supplier products

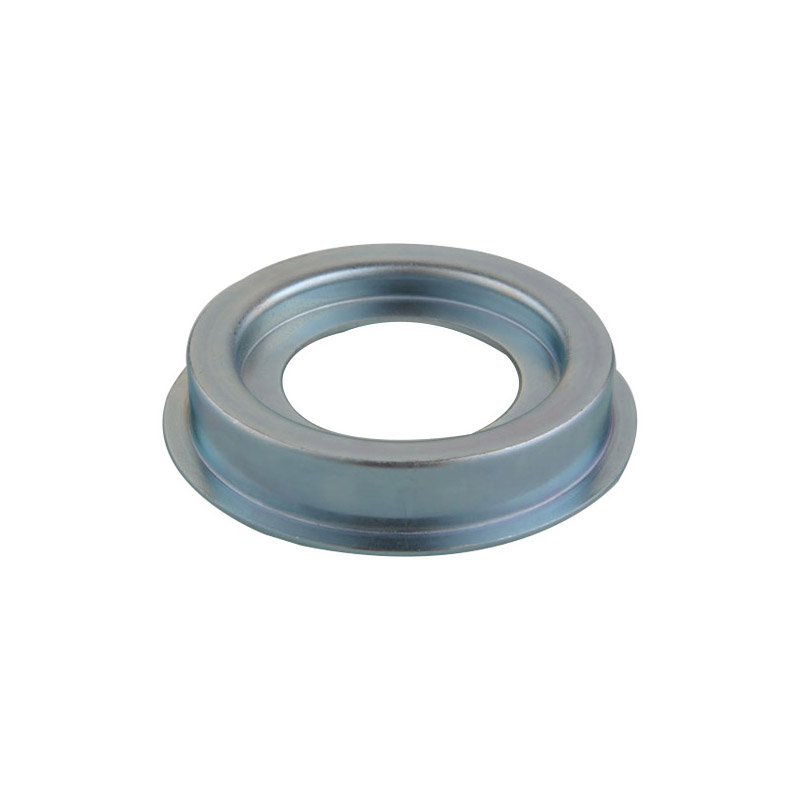

| Cold Forging Flange Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Information Abo... | |

| Sheet Metal Stamped Components | Features of sheet metal stamping dies: ·Product name: Sheet Metal Stamped Components·Material:Carbon Steel, Barss, Copper, Stainless ... | |

| Carbon Steel CNC Milling Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Features ... | |

| Precision Metal Stamping Parts | Precision Metal Stamping China Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin:... | |

| METAL STAMPING PARTS | As China metal stamping parts manufacturerand a cnc parts manufacturer,our core competence is the production of customized metal stamping parts chi... |