Glass Polishing Slurry

We are the premier glass polishing powder factoryin the industry. Our goal is to provide our customers with the highest quality product available to ensure their glass polishing needs are met.

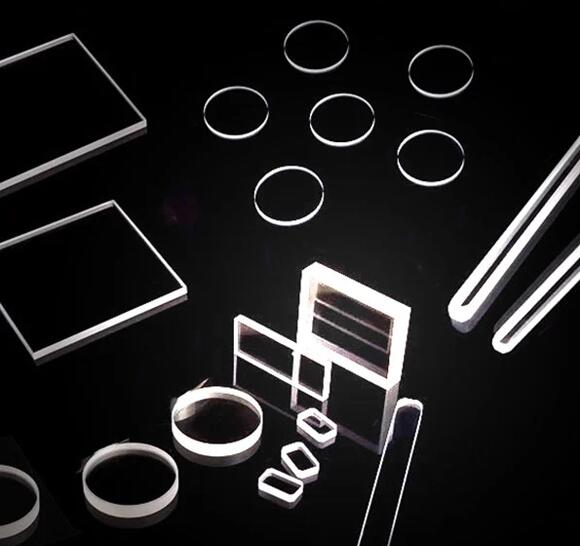

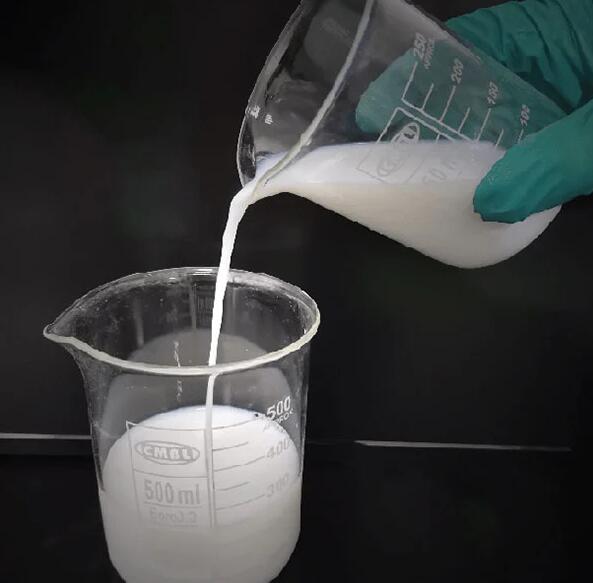

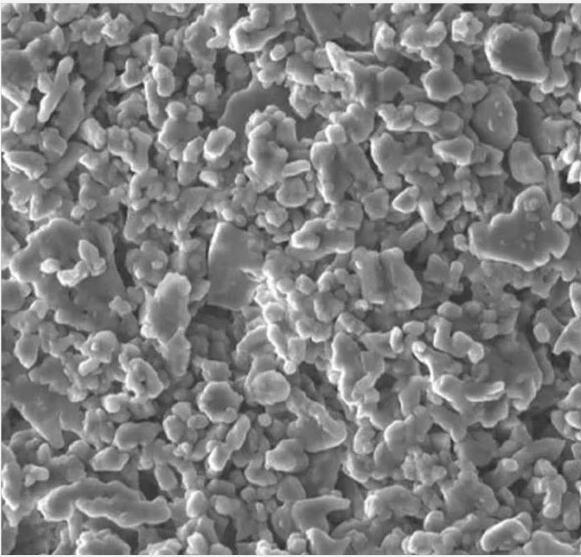

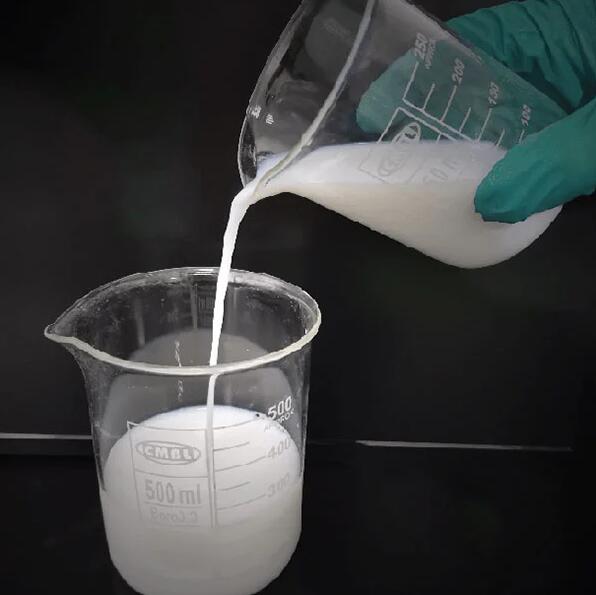

We choose quality abrasive to produce water-based polishing slurry, ensuring it is non-toxic and safe to use. It is designed to remove scratches, blemishes, and other imperfections from glass surfaces while still preserving the integrity of the glass. Our slurry is also easy to apply and will leave a smooth, streak-free finish. Kona provides different polishing slurry for different types of glass material, such as Alumina abrasive suspension for Plastic Lens glass, Cerium Oxide suspension for Quartz glass, Nona Colloidal Silicafor precision glass polishing.

We strive to provide the best customer service and support for our glass polishing slurry. We strive to provide the best customer service and support for our glass polishing slurry. We have sales engineers to answer your questions and give you tech support.

As one of glass polishing powder manufacturers, we can offer kinds of china glass polishing powderfor sale, if you have needs, please contact us.

在线联系供应商

Other supplier products

| A-Plane Sapphire Colloidal Silica | Kona series Sapphire Polishing Slurry developed for kinds of Sapphire products, such as sapphire lens and sapphire substrate. Our colloidal silica ... | |

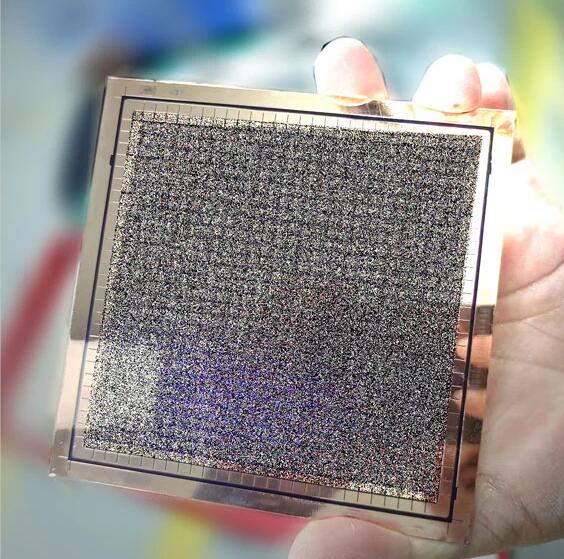

| Copper Polishing Slurry | According to the characteristics of copper material and high requirements of the 3C fabricate, Kona nano alumina water-based polishing slurry provi... | |

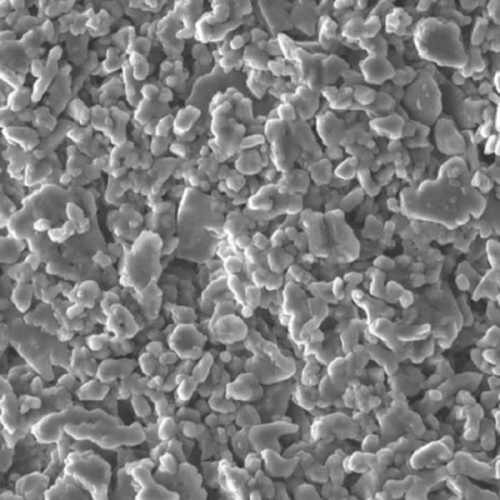

| Alumina Polishing Powder 0.6µm | Nano alumina powder polishingprovides quality polished surfaces with a high removal rate, can be used for the final polishing of a lot kinds of mat... | |

| Alumina Polishing Powder | There are a variety of different applications for alpha alumina powders according to different morphology and purity. Our alumina polishing powder,... | |

| Copper-Covered Ceramic Substrate Polishing Slurry | Copper is a good conductor. Resin substrates, metal substrates and ceramic substrates all need to be coated with copper to be used in electrical ap... |