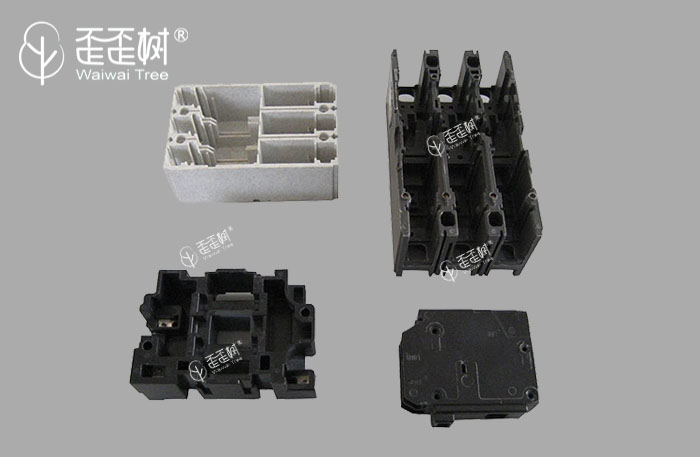

BMC/SMC Products

BMC/SMC Products Description:

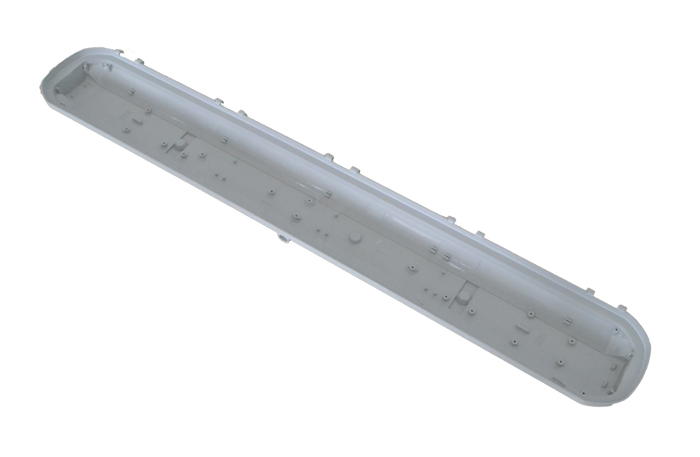

BMC, SMCthermosetting plastic products are produced by BMC and SMC plastic molding process. What is smc plastic?SMC/BMC is one of thermosetting plastics, and SMC/BMC thermosetting plastics are thermosetting molding compounds made of unsaturated polyester resin as matrix resin. The main components of SMC/BMC thermosetting plastics include resins, thickeners, low shrinkage additives, fillers, internal mold release agents, colorants, stabilizers, and the like. It is first formulated into a resin paste and then used to impregnate or blend with a reinforcing material to form a preformed molding material. According to the preforming process and the shape of the obtained preformed material, it can be divided into SMC thermosetting plastic and BMC thermosetting plastic or DMC integral molding plastic. SMC/BMC thermosetting plastics are easy to form, have low molding shrinkage, high dimensional accuracy and good processing performance. SMC/BMC thermoset plastic products have excellent electrical insulation, heat resistance, flame retardancy and good mechanical strength. SMC, BMC thermosetting plastic products are widely used in electrical, construction, civil appliances, daily necessities and other industries to process a variety of insulation, structural parts, decorative parts and daily necessities.

We provide you with SMC thermoset molding and BMC thermosetmolding.

BMC/SMC Products Features:

High insulation, chemical resistance, high fire resistance, good water resistance, accurate size, stable working performance, light weight, high strength, acid and alkali resistance, waterproof and moisture proof.

About BMC/SMC Products:

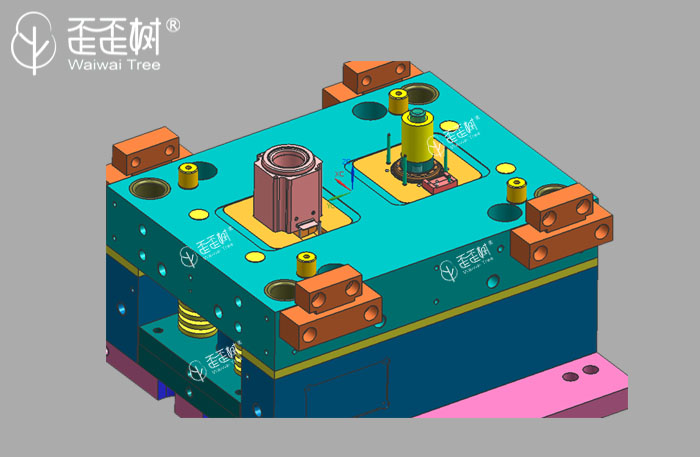

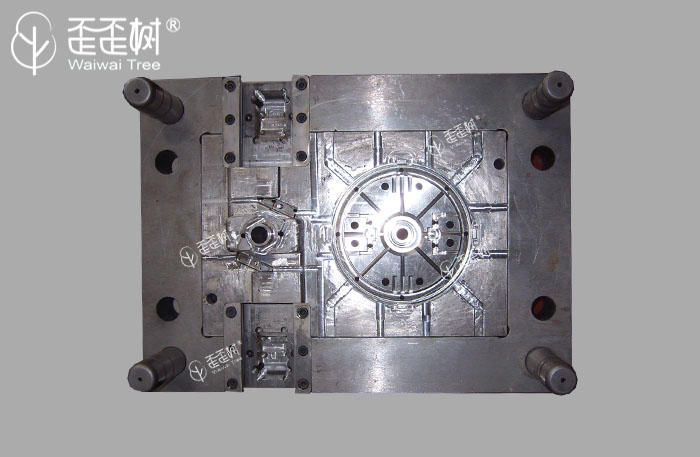

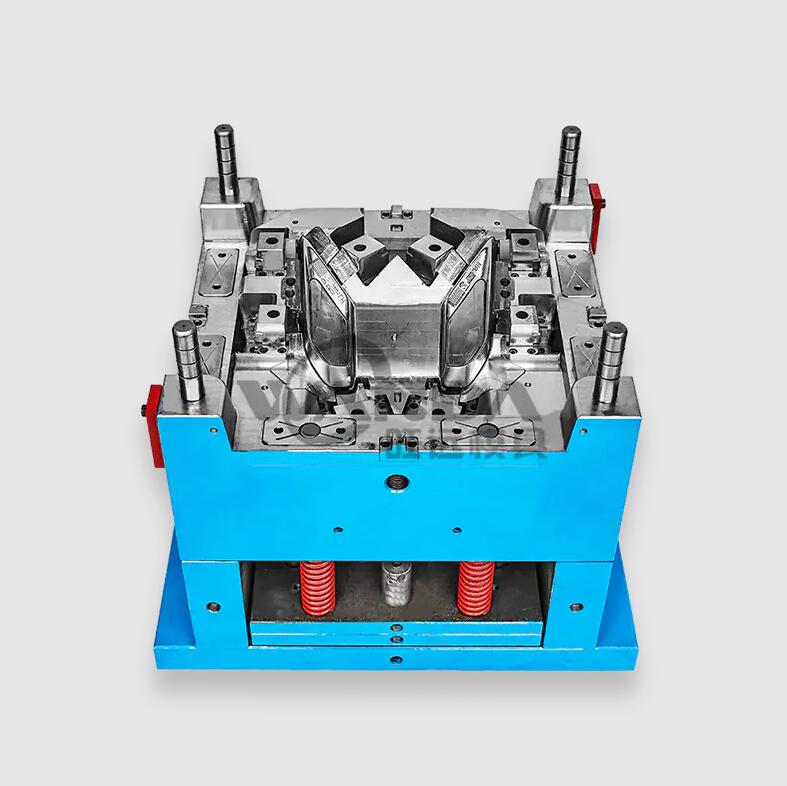

As the bmc material supplier, Zhejiang Aobang has long been committed to SMC/BMC molded parts and BMC injection parts forming processing services and SMC/BMC mold design and manufacturing. The company's strong technical strength and strong technical research and development capabilities can provide customers with SMC / BMC composite integrated solutions. The company produces various types of SMC/BMC molds, and can design and adjust the formula according to the customer's specific requirements to meet the relevant process and use requirements. It can suppress products with various properties such as flame retardant, electrical, anticorrosive, high strength and high toughness. Can be widely used in highways, automobiles, electrical, electrical, chemical, communications, railways and other fields. SMC/BMC thermoset plastic products are characterized by high mechanical properties, precise dimensions and good electrical properties. It can meet the special requirements of different products of customers, and also provide professional technical support and services for customers with different process requirements.

SMC/ BMCCompositeProducts Description:

SMC, BMC thermosetting plastic products are produced by SMC and BMC plastic molding process. What is smc plastic?SMC/BMC is one of thermosetting plastics, and SMC/BMC thermosetting plastics are thermosetting molding compounds made of unsaturated polyester resin as matrix resin. The main components of SMC/BMC thermosetting plastics include resins, thickeners, low shrinkage additives, fillers, internal mold release agents, colorants, stabilizers, and the like. It is first formulated into a resin paste and then used to impregnate or blend with a reinforcing material to form a preformed molding material. According to the preforming process and the shape of the obtained preformed material, it can be divided into SMC thermosetting plastic and BMC thermosetting plastic or DMC integral molding plastic. SMC/BMC thermosetting plastics are easy to form, have low molding shrinkage, high dimensional accuracy and good processing performance.

在线联系供应商

Other supplier products

| SMC Antenna Reflector Mould | The satellite earth antenna is the important earth satellite equipment to collect the weak signal from satellite and reduce noise to the lowest lev... | |

| SMC Cable Braket | The SMC cable bracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made b... | |

| Auto Parts And Accessories | Motor Mold Description Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the cross... | |

| Shell Moulding | Shell Moulding Description Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner a... | |

| Motor Mold | Mainly for injection molding, the design of the runner and the parting surface should be as small as possible, and the crossover, exit, protector a... |

Same products

| Precision And Durable Multi-Specification Automobile Buckle Mold | 卖方: Yueqing Huangrong Mold Co., Ltd. | Automotive door panel clip frame molds are essential tools in this process, ensuring that the cli... | |

| 定制电机模具 | 卖方: 846123 | 90 三排高速渐进冲压模具定制电机模具()90 三排高速渐进冲压模具是专为高速渐进冲压而设计的专用工具,专为高精度电机铁芯量身定制。该模具的创新设计显著提高了效率和生产力,可同时加工多种产品。主... | |

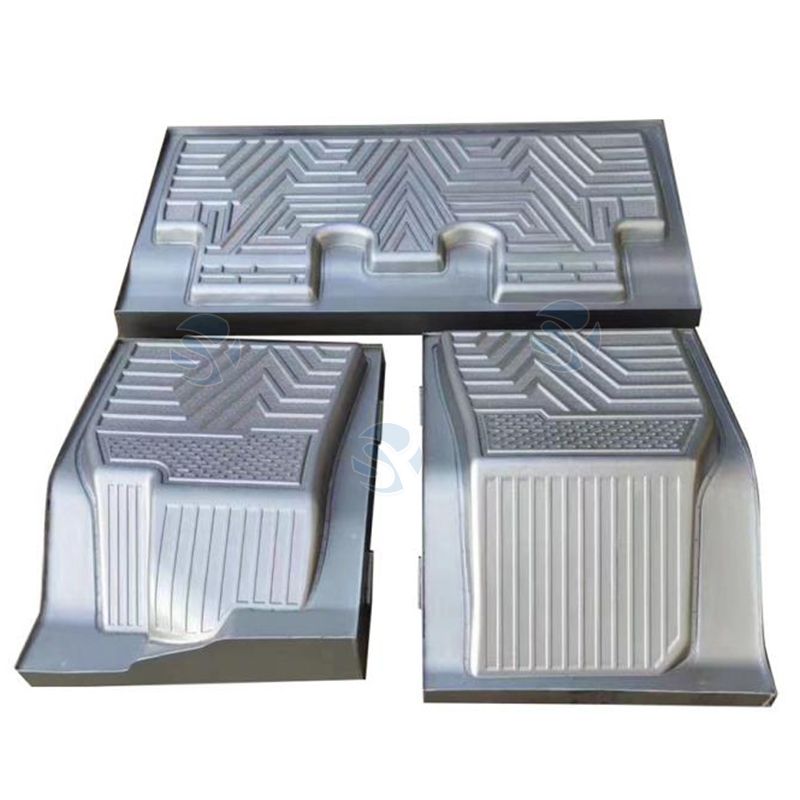

| Car Mat Aluminium Vacuum Mould | 卖方: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

| Auto Mould-Safe and Convenient Operation | 卖方: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | 卖方: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... |