BMC, SMC, GRP, GFK Building & Decoration Materials

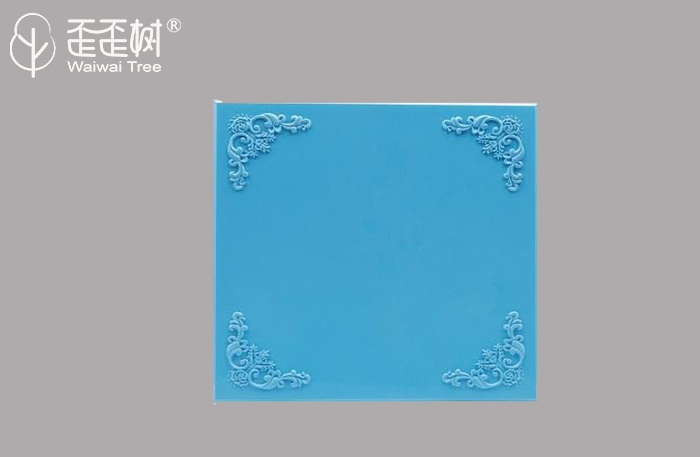

Aobang composite Building Decoration materialisdivided into: BMC building decoration material, SMC building decoration material, GRP building decoration material, GFK building decoration material.

Building decoration materials may have heard of commonly used bmc materialssuch as sandstone and cement. BMC, SMC, GRP, and GFK composite materials have been heard by few people. It is a new type of material. What are the advantages?

It can be known that it is resistant to water and oil and excellent corrosion resistance, and its heat resistance and good electrical properties are its advantages, making it stand out in the highly competitive material market. In addition, it can be further found that the composite material has higher requirements for the post-use environment than other materials.

We can provide GRP building productsfor you.

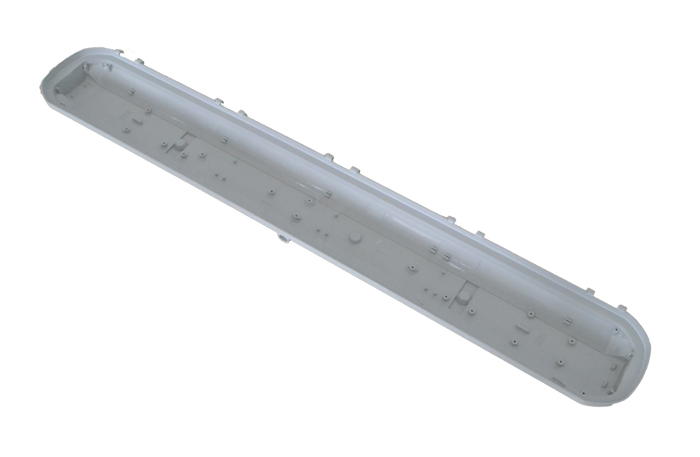

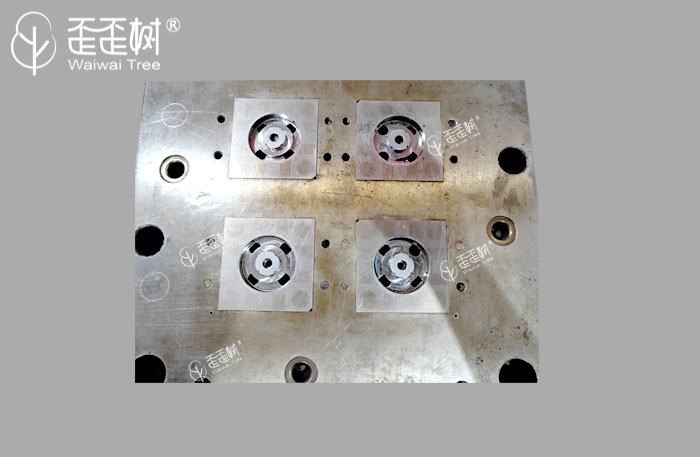

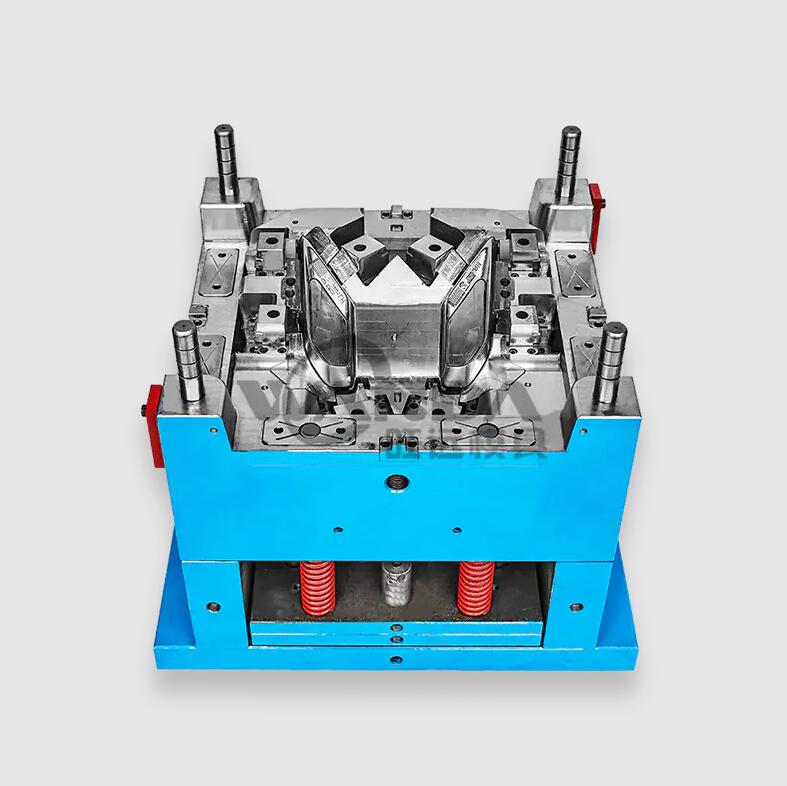

SMC and BMC compositerequire heating rather than cooling systems. The temperature of the mold is usually between 130 and 160. It is very important to keep the temperature of the mold and the exhaust gas when designing the mold. The mold is easier to fill, the product is not easy to be deformed, and the surface is better. Commonly used heating systems are steam, oil and electric heating rods.

Vacuum assisted systems for SMC and BMC molding: Products with Class A surfaces are usually vacuum-assisted, and the internal cavity and vacuum insulation of the mold are very important. The mold must have a sensor and a vacuum system to measure the mold temperature and pressure vacuum. Production SMC and BMC molds must guarantee high quality, long life and economy. Aobang Technology Co., Ltd.'s years of experience in the production of SMC and BMC molds and proficiency in machine, mold, material and process can ensure the maximum benefit of customers.

在线联系供应商

Other supplier products

| BMC, SMC, GRP, GFK Roof Tiles | What Is GFK Material BMC, SMC, GFK material, GRP roofing materialsare glassfiber reinforced plastic, also known as glassfiber roof, which are co... | |

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safety ... | |

| Shell Moulding | Shell Moulding Description Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner a... | |

| Flange Molding | Flanged joint is the main connection method in pipeline construction. Compared to thermoplastic, thermoset composite can be reprocessed. With high ... | |

| BMC/SMC Molds | Custom high Precision Compression/Injection Moulds Manufacturing with fast lead time BMC/SMC Mould Manufacturer As one of sheet molding compoun... |

Same products

| 定制电机模具 | 卖方: 846123 | 90 三排高速渐进冲压模具定制电机模具()90 三排高速渐进冲压模具是专为高速渐进冲压而设计的专用工具,专为高精度电机铁芯量身定制。该模具的创新设计显著提高了效率和生产力,可同时加工多种产品。主... | |

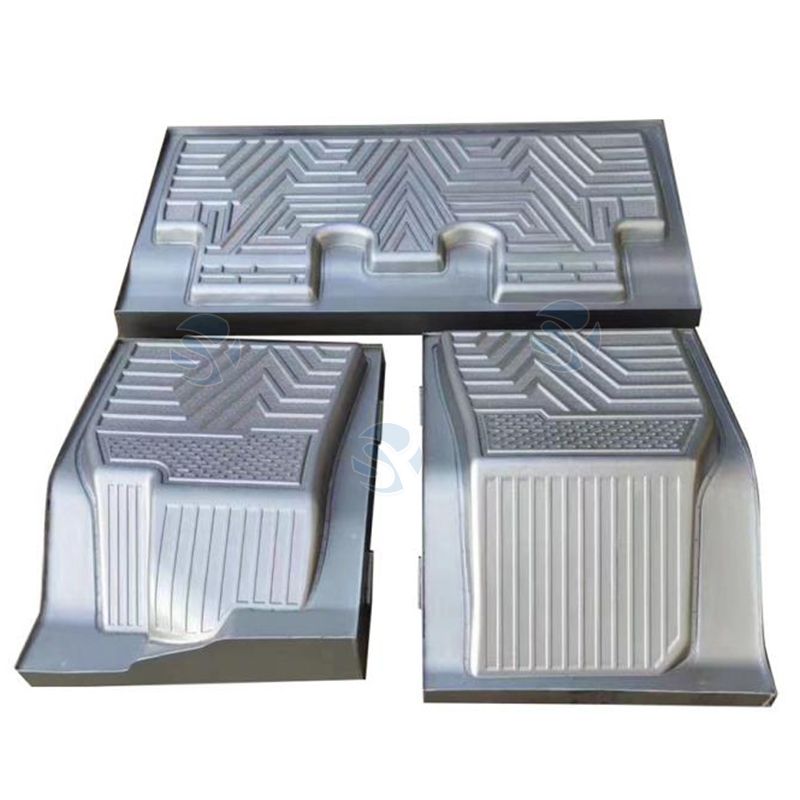

| Car Mat Aluminium Vacuum Mould | 卖方: Hebei Shuiyuan Trading Co., Ltd | Product Description Vacuum molding is the most popular technology for shaping plastic raw mate... | |

| Auto Mould-Safe and Convenient Operation | 卖方: Taizhou Wanda Plastic Mould Co.,Ltd. | Product Name Auto Parts Mould Brand Wanda Mould Model No specific Model Material S136/H1... | |

| SMC Cable Braket | 卖方: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The ... | |

| SMC/BMC Antenna Reflector | 卖方: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | (1) High precision, high efficiency, and high gain. The most important job of using SMC/BMC for ... |