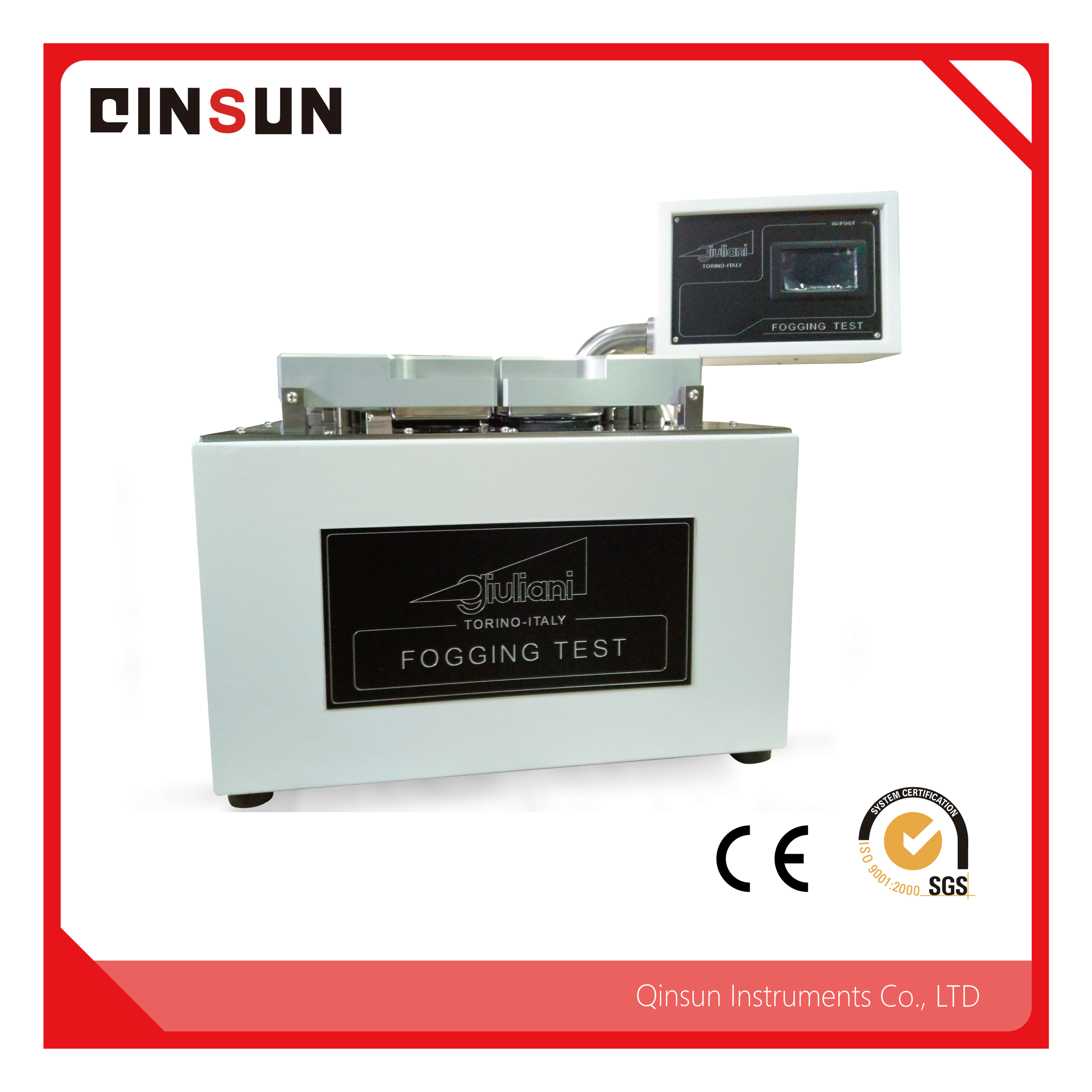

fogging test equipment

Fogging tester is used to determine the windscreen fogging according to ISO, DIN, ASTM and other automotive standards. The equipment has a compact design with the heating bath and cooling bath integrated in one casing. For cooling the water bath, the instrument is normally connected to tap water of max 18 °C. If the tap water is too warm, a model EB 03C can be supplied with a built in cooling system with Peltier elements.

Working Principle:

The main frame of the tester includes a water sink fully filled with specified ethylene glycol, which can reach a high temperature. At the time of testing, leather specimens are put in the six standard glass containers filled with high temperature liquid, and the stainless steel containers are placed above each glass. Relying on the constant water flow distribution, the temperature can maintain at 20℃ constantly, and it can be adjusted through the regulation device connected to the main frame. This controlled environment condition will generate a layer of “fog” on the surface of specimens. The operator can determine the fogging characteristics of materials based on gravimetric analysis method or refraction method.

Test Methods:

It applies to the following test methods:

1) Gloss Method: the sample cup is heated by the fog evaporated gas condensing on cold glass by glass gloss values were compared before and after condensation and calculated, the sample can be drawn into the fog value.

2) Gravimetric method: the sample cup is heated by the fog evaporated gas condensing on cold aluminum foil, aluminum foil condensed by weighing before and after the change in weight, the sample can be drawn from the atomization - the weight of condensate.

3) Haze method: the sample cup is heated by the fog evaporated gas condensing on cold glass, through the haze value before and after the glass condensate compare and calculate, the sample can be drawn into the fog value.

Standards

DIN 75201 Determination of the fogging characteristics of trim materials in the interior of automobiles

ISO 6452 Rubber or plastics coated fabrics-determination of fogging characteristics of trim materials

in the interior of automobiles

SAE J1756 Test procedure to determine the fogging characteristics of interior automotive materials

QB/T 2728 Leather-physical and mechanical test-determination of fogging characteristics.

BS EN 14288 Leather - Physical and mechanical tests - Determination of fogging characteristics

PV 3920 Determination of fog value (F) of non-metallic interior materials

PV 3015 Non-metallic materials for interior trim-determination of condensable constituents.

ES-X83231 Standard test method-For fogging of interior materials

NES M0161 Interior materials fog test method

D45 1727 TRIM MATERIALS AND PARTS FOR INTERIOR AND PASSENGER COMPARTMENT PARTS - FOGGING - CONDENSATION

GM 9305P Determination of fogging characteristics of automotive interior trim materials

TSM 0503G Fogging test method for non-metallic materials

Features:

CONSTRUCTIVE CHARACTERISTICS:

· Internal carrying plane, in structural treated steel, anti-acid painted.

·External protection in sheet steel of proper thickness, anti-acid treated and painted with epoxy resin.

·six work places 18/8 Inox steel test room.

·18/8 Inox steel lift able cooling system.

·Rapid clutch Agitation System.

· Armored resistances.

· Security thermostat.

· Cooling liquid and relief entry etching with rubber-carrier.

SECURITY NORMS:

· Safety Magnetic Switch.

· Digital thermos regulator and microprocessor.

· Electronic auto programmable timer

· START-STOP switches,

· Warning Lamps.

· End test buzzer hint signal

It applies to the following test methods:

1) Gloss Method: the sample cup is heated by the fog evaporated gas condensing on cold glass by glass gloss values were compared before and after condensation and calculated, the sample can be drawn into the fog value.

2) Gravimetric method: the sample cup is heated by the fog evaporated gas condensing on cold aluminum foil, aluminum foil condensed by weighing before and after the change in weight, the sample can be drawn from the atomization - the weight of condensate.

3) Haze method: the sample cup is heated by the fog evaporated gas condensing on cold glass, through the haze value before and after the glass condensate compare and calculate, the sample can be drawn into the fog value.

Standards

DIN 75201 Determination of the fogging characteristics of trim materials in the interior of automobiles

ISO 6452 Rubber or plastics coated fabrics-determination of fogging characteristics of trim materials

in the interior of automobiles

SAE J1756 Test procedure to determine the fogging characteristics of interior automotive materials

QB/T 2728 Leather-physical and mechanical test-determination of fogging characteristics.

BS EN 14288 Leather - Physical and mechanical tests - Determination of fogging characteristics

PV 3920 Determination of fog value (F) of non-metallic interior materials

PV 3015 Non-metallic materials for interior trim-determination of condensable constituents.

ES-X83231 Standard test method-For fogging of interior materials

NES M0161 Interior materials fog test method

D45 1727 TRIM MATERIALS AND PARTS FOR INTERIOR AND PASSENGER COMPARTMENT PARTS - FOGGING - CONDENSATION

GM 9305P Determination of fogging characteristics of automotive interior trim materials

TSM 0503G Fogging test method for non-metallic materials

Features:

CONSTRUCTIVE CHARACTERISTICS:

· Internal carrying plane, in structural treated steel, anti-acid painted.

·External protection in sheet steel of proper thickness, anti-acid treated and painted with epoxy resin.

·six work places 18/8 Inox steel test room.

·18/8 Inox steel lift able cooling system.

·Rapid clutch Agitation System.

· Armored resistances.

· Security thermostat.

· Cooling liquid and relief entry etching with rubber-carrier.

SECURITY NORMS:

· Safety Magnetic Switch.

· Digital thermos regulator and microprocessor.

· Electronic auto programmable timer

· START-STOP switches,

· Warning Lamps.

· End test buzzer hint signal

Technical Parameter:

Hot bath temperature range: room temperature ~ 150 ℃ (room temperature ~ 280 ℃ optional)

High-temperature tank temperature control accuracy: ± 0.1 ℃ (150 ℃)

Low bath temperature range: 0 ~ 100 ℃

Cold tank temperature control accuracy: ± 0.1 ℃

High temperature trough Dimensions: 670 mm (L) × 490 mm (B) × 540 mm (H)

Cryogenic tank Dimensions: 400 mm (L) × 220 mm (B) × 520 mm (H)

Temperature tank Weight: 32kg (not including the thermally conductive medium)

Cryogenic tank Weight: 15kg (not including the thermally conductive medium)

Power: AC 220V 50Hz

Weight: 50kg

Size: 500 * 650 * 600mm

Temperature stability: ± 0.1 ° C (200 ° C)

Heating power: 3KW

Cooling capacity: 500W

Data communication: multi-function remote sensor and USB port

Safety magnetic switch

Warning Light

Test completion tips

在线联系供应商

Other supplier products

| Launderometer coloured textile washing fastness tester | Washing Fastness Tester (Launderometer), to determine color fastness to washing or dry cleaning to ISO, AATCC standards. The washing fastness test... | |

| Circular Locus Pilling Test machine | The instrument is used to test the wool fabric, chemical fiber cotton, blended, knitted, woven fabric pilling conditions to identify product qualit... | |

| Oscillator and Wyzenbeek Abrasion Tester complies with ASTM D4157 | Oscillator and Wyzenbeek Abrasion Tester complies with ASTM D4157 is also named as Wyzenbeek Abrasion Tester, used to determine the abrasion resist... | |

| Precision Fiber Microtome | Precision Fiber Microtome Testing Standards: ASTM D2130, BS 2043, DIN 53811, ISO 137, IWSTM 24, IWTO 8-6 Applications: Precision Fibe... | |

| vehicle windscreen fogging tester with SAE J1756 | Fogging tester is professionally designed for the fogging characteristics evaluation of volatile constituents of decorating materials used in cars ... |

Same products

| MECHANIC ROBOT 6560T-B11HD 三目立体显微镜 | 卖方: 深圳维客修科技有限公司 | 描述 机械师标准版6560T-B11三目立体显微镜,放大倍数6.5-60X,45度倾斜360度旋转观察头,带WF10X25可调目镜。非常适合维修手机、平板电脑、手表等电子产品,适用于电子电路板、... | |

| ZM-6552TH 0.65X - 5.2X 双目三目立体显微镜,适用于主板维修 | 卖方: 深圳维客修科技有限公司 | 描述 Greenough ZM-6552TH 0.65X-5.2X双目/三目立体变焦显微镜适用于手机主板/电子电路板CPU BGA焊接维修、珠宝鉴定修复、实验室观察、学术研究等。ZM-6552T... | |

| MEGA-IDEA iSocket For Testing of iPhone 16-16 Pro Max Motherboards Layering Repairs | 卖方: Phonefix | MEGA-IDEA iSocket for functional testing of iPhone 16/16 Plus/16 Pro/16 Pro Max motherboards duri... | |

| Vibration Fiber Fineness Tester | 卖方: G238BB Electronic Crockmeter | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... | |

| Fiber Length Analyzer | 卖方: G238BB Electronic Crockmeter | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... |