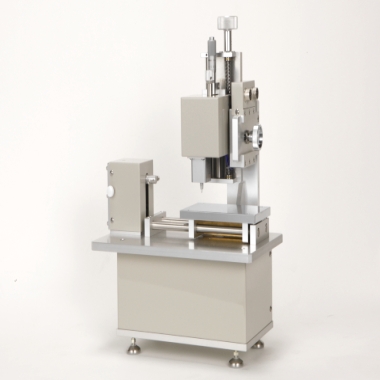

Office Chair Caster Durability Tester

The Office Chair Caster Durability Tester is designed to evaluate the rolling durability, structural reliability, and service life of office chair casters under controlled load and motion conditions. The equipment simulates long-term rolling, rotation, stopping, and reversing movements of chair casters on floor surfaces to assess wear, deformation, and functional degradation. It is widely used for quality control, product certification, and durability verification of office seating products.

Application

(1) Durability and life-cycle testing of office chair casters under specified load conditions.

(2) Rolling wear evaluation of casters used on hard floors, plastic floors, and resilient floor coverings.

(3) Performance verification of complete office chairs equipped with multi-caster bases.

(4) Quality control testing for chair manufacturers during product development and mass production.

(5) Comparative testing of different caster materials, wheel structures, and hardness grades.

(6) Reliability testing of casters for use in commercial offices, public buildings, and educational facilities.

(7) Compliance testing for office chair products required to meet national and international standards.

Standards

Chinese Standards

(1) GB/T 4085 – Office furniture — Chairs — Strength and durability requirements

(2) GB/T 10357.5 – Furniture — Strength and durability of seating — Part 5: Strength and durability of chair bases and castors

(3) QB/T 2280 – Office chair

(4) GB/T 24506 – Office furniture — Chairs — General technical requirements

European Standards

(5) EN 425 – Resilient and laminate floor coverings — Castor chair test

(6) EN 1335-2 – Office furniture — Office work chair — Safety requirements

(7) EN 1335-3 – Office furniture — Office work chair — Test methods

(8) EN 1022 – Domestic furniture — Seating — Determination of stability

(9) EN 12529 – Castors and wheels — Test methods and requirements

ISO International Standards

(10) ISO 4918 – Resilient floor coverings — Castor chair test

(11) ISO 5970 – Furniture — Chairs and tables — Determination of stability

(12) ISO 7173 – Furniture — Chairs and stools — Determination of strength and durability

(13) ISO 24344 – Resilient floor coverings — Determination of flexibility and damage under rolling load

(14) ISO 4210 (relevant principles) – Cyclic durability and rolling load test methodology (reference)

North American Standards

(15) ANSI/BIFMA X5.1 – Office Seating — Performance Requirements

(16) ANSI/BIFMA X5.11 – General-Purpose Large Occupant Office Chairs

(17) ASTM F2057 – Rolling load resistance of resilient floor coverings

(18) ASTM D6112 – Resilient flooring — Castor chair testing method

(19) UL 1286 – Office furnishings (related caster and mobility performance reference)

Flooring & Surface Related Standards

(20) ISO 10581 – Resilient floor coverings — Homogeneous and heterogeneous PVC flooring

(21) ISO 10582 – Resilient floor coverings — Heterogeneous PVC flooring

(22) EN 649 / EN 651 / EN 685 – Classification and performance of resilient floor coverings

(23) ASTM F1700 – Solid vinyl floor tile (caster performance reference)

Application-Oriented Reference Standards

(24) DIN 4551 / DIN EN 12529 – Castors for furniture — Performance and durability

(25) JIS S 1203 – Office furniture — Chair strength and durability test methods

(26) CSA Z412 – Office ergonomics and seating performance (reference for caster use conditions)

Features

(1) PLC touch screen control system with simple, intuitive operation interface.

(2) Full aluminum profile frame structure with surrounding protective cover for enhanced safety and durability.

(3) Thickened all-aluminum load base with an additional stainless steel plate to facilitate floor replacement and resist scratching and corrosion.

(4) Reducer-driven caster load block and test base enabling adjustable speeds and one-key start operation.

(5) Stable platform rotation with automatic stop, dwell, and reverse motion to simulate real usage conditions.

(6) Designed for long-duration testing up to millions of cycles with reliable operation.

Technical Parameters

| Parameter | Specification |

|---|---|

| Control mode | PLC touch screen |

| Load | 90 kg |

| Platform diameter | 2750 mm |

| Sample support platform material | Hard plastic |

| Sample support platform size | Diameter 480 ±5 mm, thickness 7 ±2 mm |

| Caster wheel diameter | 50 ±2 mm |

| Caster wheel width | 23 ±3 mm |

| Crank distance | 32 ±2 mm |

| Wheel hardness | Shore A (95 ±5) |

| Distance from casters to platform | 198 ±1 mm |

| Distance between three casters | 130 ±1 mm, distributed at 120° |

| Installation distance between any two casters | 225 ±5 mm |

| Caster test life | 2,000,000 cycles |

| Platform speed | 19 ±1 r/min |

| Platform operation cycle | Rotate (180 ±10) s → stop (5 ±2) s → reverse |

| Caster speed | 50 ±1 r/min |

Test Procedure

(1) Install the floor sample securely on the test base using adhesive or fixing method as required.

(2) Mount the office chair or caster assembly on the sample support platform.

(3) Apply the specified load to the caster load block.

(4) Set platform speed, caster speed, and test cycle parameters via the PLC touch screen.

(5) Start the test; the platform rotates, stops, and reverses automatically according to the preset program.

(6) Continue the test until the specified number of cycles is reached or failure occurs.

(7) Inspect casters and floor surface for wear, deformation, or functional failure.

Maintenance Information

(1) Regularly inspect caster fixtures and load blocks for secure fastening.

(2) Clean the platform and floor base after testing to prevent debris accumulation.

(3) Periodically check PLC control system and reducer operation.

(4) Replace worn floor samples promptly to ensure test accuracy.

(5) Store the equipment in a dry, stable laboratory environment.

在线联系供应商

Other supplier products

| Bonding Strength Measuring Instrument | The tack - holding tester, also known as the tack - holding property tester, tack - holding force tester, or holding - power tester, is a device sp... | |

| 20L Spherical Explosion Tester | 20L Spherical Explosion Tester is characterized by accurate test data and ease of use. Its through the compressed air will be a certain mass of dus... | |

| Aerosol Foams Flammability Tester | Product Introduction This product complies with "Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria" 31.6 Flammabi... | |

| Metal Corrosivity Tester | standards GB/T 15970 ISO 7539 ASTM G31 GB/T 10125 Scope of Application The metal corrosivity tester is designed and manufactured in line with... | |

| UV Weathering Testing Machine | Features and Benefits 1.Accelerated Aging Simulation Simulates months or years of outdoor UV exposure in just a few days or weeks. Ideal for asse... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |