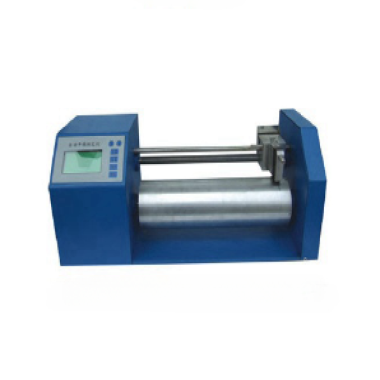

Commercial dry cleaner

The Commercial Dry Cleaner is a high-performance rotary and hydrocarbon-based dry cleaning machine designed for professional textile care and industrial applications. Engineered for precision, efficiency, and environmental compliance, it is suitable for large-scale garment care, industrial degreasing, and metal surface cleaning. The machine integrates advanced digital controls, eco-friendly refrigerants, and energy-efficient systems to ensure sustainable and reliable operation.

Application

(1) Professional Dry Cleaning – Suitable for hotels, luxury garment care centers, and commercial laundries.

(2) Industrial Textile Care – Ideal for cleaning uniforms, workwear, and protective clothing in factories and institutions.

(3) Degreasing & Cleaning – Used in metal surface cleaning and industrial equipment maintenance.

(4) Laboratory & R&D – Can be applied for textile testing, material cleaning studies, and process optimization.

(5) Garment Quality Assurance – Ensures that textiles are cleaned without damage, maintaining fiber integrity and appearance.

Standards

(1) BS EN ISO 3175 – Textile machinery and commercial dry cleaning requirements.

(2) M+S P66+67 – Safety and performance standards for commercial dry cleaning machines.

(3) AATCC 158 – American Association of Textile Chemists and Colorists standard for dry cleaning testing.

(4) ISO 14001 – Environmental management compliance for sustainable manufacturing.

(5) EU Eco-label – Certification for environmental performance.

(6) CE Safety Approvals – Compliance with European safety directives.

Features

(1) Digital Precision Control – Microprocessor-based speed controller with preset counter (1–9999 rpm).

(2) Energy Efficiency – Motors designed to reduce power consumption by up to 30%.

(3) Eco-Friendly Refrigerants – Compatible with R600a or R134a for low environmental impact.

(4) Water Recycling System – Up to 95% water reuse to minimize resource consumption.

(5) Robust Construction – Durable rotary drums and hydrocarbon systems for continuous industrial use.

(6) Versatile Cleaning – Capable of processing a wide range of textiles, including delicate and industrial fabrics.

(7) Local Support – 24/7 technical assistance and customized maintenance programs.

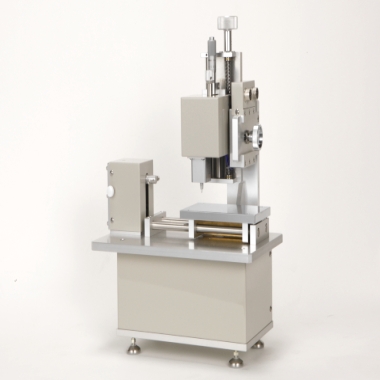

Technical Parameters

| Parameter | Specification |

|---|---|

| Abrasive | AFS 50 to 70 test grit (~200 microns) |

| Grinding Wheel Speed | 200 rpm |

| Abrasive Flow Rate | 300–400 g/min |

| Test Load | 45–130 N |

| Grinding Wheel Diameter | 228 mm |

| Chlorobutyl Rubber Hardness | A 58–62 (Shore durometer) |

| Speed Controller | Microprocessor-based digital preset counter |

| Power Supply | AC 220V/50Hz (typical, depending on model) |

| Dimensions (L×W×H) | Model-dependent |

| Weight | Model-dependent |

Accessories

(1) Standard rotary drum attachments.

(2) Hydrocarbon solvent system kit.

(3) User manual and compliance certificate.

(4) Optional water recycling module and spare parts kit.

Test Procedures

(1) Fill the machine drum with the required textiles or materials.

(2) Set the appropriate cleaning mode, speed, and test load via the digital controller.

(3) Add cleaning solvent or hydrocarbon as needed.

(4) Start the machine, allowing rotation and cleaning cycles to run automatically.

(5) Monitor digital readouts for cycle completion and speed control.

(6) Upon completion, safely unload textiles and process solvent/water recycling as required.

Maintenance Information

(1) Regularly inspect drum, bearings, and seals for wear.

(2) Clean filters and solvent lines to prevent clogging.

(3) Calibrate speed controller and sensors periodically.

(4) Replace worn abrasive wheels or brushes according to operating hours.

(5) Follow manufacturer’s guidelines for safe handling of hydrocarbon solvents.

在线联系供应商

Other supplier products

| Office Chair Caster Endurance Testing Machine (for Office Chair Caster Durability Tester) | Implementation standards GB/T4085 EN425 Product features 1. The instrument adopts PLC touch screen control, simple and intuitive operation; 2. ... | |

| Strength Tester for Lead - end of Photovoltaic Modules | Standard IEC 61215-2:2016: Terrestrial Photovoltaic (PV) Modules – Test Requirements for Electrical and Mechanical Components CE Certific... | |

| Incline Impact Tester | Standard ASTM D7748: Impact resistance testing of packaging and transport systems. ISO 13355: Automotive component durability evaluation under ... | |

| Ink drying apparatus | How it works: The working principle of the ink drying instrument is based on simulating the drying environment of the ink in the printing process,... | |

| Guidewires Tip Flexibility Tester | The Guidewires Tip Flexibility Tester is designed and manufactured in accordance with the relevant clauses of YY/T 1554-2017 and YY 0450.1-2003. It... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |