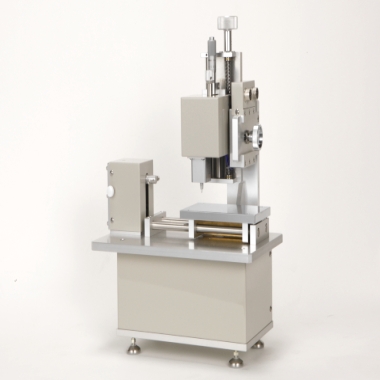

Catheter Vacuum Leak Tester

The Catheter Vacuum Leak Tester is a professional device used to detect leaks in medical catheter systems under vacuum conditions. Its primary purpose is to ensure the sealing integrity and safety of catheters during use, preventing medical accidents caused by leaks. This tester can be widely used for leak detection in various medical catheters, such as suction catheters, drainage catheters, anesthesia catheters, and endotracheal tubes.

Applications

The catheter vacuum leak tester is a professional device used to detect leaks in medical catheter systems under vacuum conditions. It is mainly used to ensure the sealing and safety of catheters during use and prevent medical accidents caused by leaks. This tester can be widely applied to the leak detection of various medical catheters, such as suction catheters, drainage catheters, anesthesia catheters, endotracheal tubes, etc.

Standards

GB 15812.1 - 2005 :Non - Vascular Intravascular Catheters - Part 1: General Performance Test Methods

GB 8368 :Disposable Infusion Sets

YY 0489 - 2004 :Test Method for Piston Tightness of Disposable Sterile Syringes

Features

1. High-precision measurement: It can quickly and accurately detect the location and size of leaks in the pipeline system, enabling precise measurement of minute pressure changes and flow differences.

2. Safe and reliable: It prevents safety accidents and quality problems caused by leaks, ensuring the safety and stability of the production process.

3. Easy to operate: The operation interface is simple and clear, allowing users to complete the testing process by following the prompts. Some testers also feature user-level access control and a comprehensive password protection scheme to ensure data integrity, standardization, and traceability.

4. Multifunctional: Some advanced testers offer features such as real-time data display, data recording and analysis, test report generation, and multiple testing modes, meeting the needs of different users.

Technical Parameters

| Parameter | Specification |

|---|---|

| Measuring Range | Usually 0 to -90kPa, which can meet the negative-pressure testing requirements of various catheters |

| Accuracy | Generally reaching level 0.1 to ensure the accuracy of test results |

| Vacuum Maintenance Performance | Equipped with an automatic pressure-holding function to ensure the stability of the vacuum during the test |

| Test Time | Setting range: 1 to 9999 seconds; error ≤ ±1 second |

| Power Supply | Usually 220VAC 50Hz or 120VAC 60Hz, adapting to voltage requirements of different regions |

| Net Weight | Approximately 20kg (varies by model) |

Accessoriess

Standard accessories include: specialized connection adapters for different sizes of medical catheters (compatible with various catheter interfaces such as suction tubes and drainage tubes), vacuum-sealed connecting tubing (for connecting the main unit to the vacuum tank), sample fixing clamps (to secure the catheter under test), standard leak calibration components (to ensure the accuracy of the equipment's measurements), operating instructions, and a calibration certificate.

Test Procedures

Open-system catheter: Open the catheter vacuum control device to the release position, turn on the vacuum pump, and adjust the flow rate to the specified value (e.g., 30 L/min).

Closed-system catheter: Remove the pressure gauge, turn on the vacuum control device and vacuum pump, adjust the flow rate to the specified value, then switch the vacuum control device to the closed position, and reattach the pressure gauge. Read and record the residual vacuum value measured on the pressure gauge, which is usually expressed in kPa. For respiratory tract suction catheters, the residual vacuum should not exceed the specified value (e.g., 0.33 kPa or 3.4 cmH₂O).

在线联系供应商

Other supplier products

| Plastic Friction and Wear Tester | Product Description: Plastic sliding friction wear tester consists of two main parts: the host machine and intelligent control system, which can b... | |

| Friction and wear testing machine | Standards ASTM G99-04 ASTM G77-16 ISO 9352:1995 GB/T 12444-2006 GB/T 12607-2007 GB/T 1865-2009 Application field Petrochemical: Used to ass... | |

| Single - Strand Bending Test device | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to easily measure and quantify softness, elasticity, ... | |

| Coating thickness gauge/film thickness gauge | Standard Coating Thickness Gauge complies with international standards includingASTM B499,ASTM D1400,ISO 2178,ISO 2360, andGB/T 4956, ensuring rel... | |

| Bending Tester | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rigid Plastics) SAE J2748 (Automotive Composite Flex... |

Same products

| Gas Oxidizing Property Tester | 卖方: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | 卖方: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | 卖方: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | 卖方: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | 卖方: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |