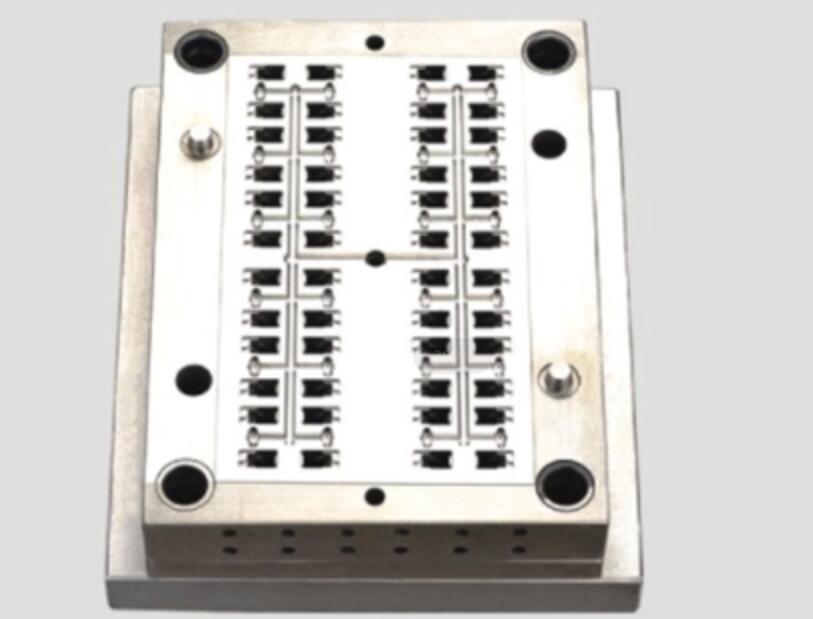

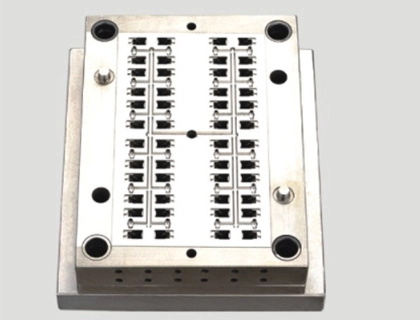

SYRINGE GASKET MOLD

It can be used for all kinds of dimension of pistons. There are materials of 4Cr13 or P20H, 2738, 718 stainless steel and etc. It can be selected for mold frame, material customer nominated is acceptable. It is the high precision of mold inner insert is S136, 2316 mirror stainless steel or others required by customers. Our mold has sound structure, and stable behavior, which is good for promoting productive efficiency.

USAGE METHOD OF SYRINGE GASKET MOLD

Prepare the mold, ensure the mold is clean and dry.

Prepare the injection molding machine: Select the appropriate injection molding machine and set it up according to the manufacturer's instructions. Preheat the machine and mold to the recommended temperature.

Load the material: Load the appropriate plastic material, such as Silicone, into the injection molding machine hopper. Ensure that the material is clean, dry, and free of contaminants.

Inject the material: Activate the injection molding machine, and the plastic material will be molten and injected into the mold cavity to fill the space of the gasket.

Allow the plastic to cool: After injection, allow the plastic to cool and solidify within the mold.

Eject the finished product: Once the plastic has cooled completely, eject the finished products by using an ejector system or opening the mold plate.

ADVANTAGES OF SYRINGE GASKETMOLD

Consistency: The use of a mold ensures a consistent size, shape, and quality of the gasket produced every time.

Time-saving: Injection molding is a fast and efficient process that produces multiple gaskets simultaneously, reducing production time per piece.

Cost-effective: Injection molding allows for the mass production of gaskets at a lower cost per piece than other production methods.

Customization: Mold design allows for customization of the size, shape, and other features of the gasket to meet specific requirements.

High precision: Injection molding machines can produce gaskets with high precision at a tight tolerance.

Reduced material waste: Injection molding produces minimal scrap compared to other production methods, reducing material waste.

If you are looking for a reliable medical molding factory, don't hesitate to contact us!

在线联系供应商

Other supplier products

| CANNULA DIAMETER REDUCING MACHINE | The Welinktech Cannula DiameterReducing Machine is a high-precision device used to accurately reduce the diameter of cannulas quickly. It is widely... | |

| CLAMP BODY MOLD | A clamp mouldis a type of injection mold that is designed to produce the clamp body component used in clamping systems. The clamp body is a type of... | |

| HYPODERMIC NEEDLE MOLD | Welinktech Hypodermic NeedleMolds are specifically designed to produce needles for syringes that are used for various medical applications. These m... | |

| CLAMP BODY MOLD | A clamp mouldis a type of injection mold that is designed to produce the clamp body component used in clamping systems. The clamp body is a type of... | |

| NEEDLE MACHINE | The LINKPLUS syringe and needle making machineis a specialized piece of equipment that creates needles of the highest quality for use in IVs, injec... |

Same products

| Durable and Reusable YCS Welding Oil Booster for Professional Repairs | 卖方: 深圳市维客修科技有限公司 | 描述 YCS Z04助焊剂推杆5ml焊油注射器推杆,用于手机/电子PCB BGA芯片维修时轻松精准地推助焊剂油、绿油、松香、锡膏。出油稳定均匀,出胶顺畅。 特点: 1.焊油槽固定牢固,不易松动... | |

| YCS-Z04 增压焊油焊剂注射器 | 卖方: 深圳维客修科技有限公司 | 描述 YCS Z04助焊剂推杆5ml焊油注射器推杆,用于手机/电子PCB BGA芯片维修过程中轻松精确地推动助焊剂油、绿油、松香和锡膏。出油稳定均匀,出胶顺畅。 特点: 1.焊油槽固定牢固,不... | |

| RFID 动物标签 | 卖方: XIUCHENG RFID | 尺寸:1.25 X 7mm / 1.4 X 8mm / 2.12 X 8mm /2.12 X 12mm / 3 X 15mm / 4 X 32mm RF 接口:ISO 11784/11785 ... | |

| RFID microchip implant | 卖方: XIUCHENG RFID | Dimension:1.25 X 7mm / 1.4 X 8mm / 2.12 X 8mm /2.12 X 12mm / 3 X 15mm / 4 X 32mm RF Interface:IS... | |

| Multi Channel Syringe Pump | 卖方: Nanjing Runze Fluid Control Equipment Co.,Ltd | Multi Syringe Pump is a precision syringe pump specially designed for high precision liquid handl... |