400 Series Stainless Steel

400 Series Stainless Steel

Stainless steel mainly composed of ferrite in use. The chromium content is 11%~30%, and it has a body-centered cubic crystal structure. This type of steel generally does not contain nickel, and sometimes contains a small amount of elements such as Mo, Ti, Nb, etc. This type of steel has the characteristics of large thermal conductivity, small expansion coefficient, good oxidation resistance, and excellent stress corrosion resistance. , water vapor, water and oxidizing acid corrosion parts. This type of steel has the disadvantages of poor plasticity, significantly reduced post-weld plasticity and corrosion resistance, which limits its application. The application of out-of-furnace refining technology (AOD or VOD) can greatly reduce interstitial elements such as carbon and nitrogen, so this type of steel is widely used.

Martensitic stainless steel

Stainless steel whose mechanical properties can be adjusted by heat treatment, in layman's terms, is a type of hardenable stainless steel. Typical grades are Cr13 type, such as 2Cr13, 3Cr13, 4Cr13 and so on. Hardness is higher after quenching, and different tempering temperatures have different combinations of strength and toughness. It is mainly used for steam turbine blades, tableware, and surgical instruments. According to the difference in chemical composition, martensitic stainless steel can be divided into two types: martensitic chromium steel and martensitic chromium-nickel steel. According to the structure and strengthening mechanism, it can also be divided into martensitic stainless steel, martensitic and semi-austenitic (or semi-martensitic) precipitation hardening stainless steel and maraging stainless steel.

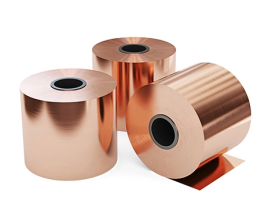

Specification Of 400 Series Stainless Steel

Features Of Ferritic and Martensitic Stainless Steel Sheet

Ferritic stainless steels include grade 430 and contain only chromium as the main alloying element. With a chromium content between 10.5-18%, they are known for their moderate corrosion resistance and fabrication properties. Manufacturability can be improved by alloy modification and is satisfactory in grades such as 439 and 444. Ferritic stainless steels cannot be hardened by heat treatment and are used in the annealed condition.

Ferritic stainless steel is magnetic. They are also less susceptible to corrosion cracking. Solderability of thin-walled sections is acceptable but degrades as part thickness increases.

Ferritic stainless steel is commonly used in: vehicle exhaust pipes, cooking utensils, architectural decoration, household appliances.

Compared with ferritic stainless steel, high carbon and low chromium content are the distinguishing features of martensitic stainless steel. Martensitic stainless steel includes 410, 420 and other steel grades. They are magnetic, have moderate corrosion resistance and poor solderability.

Martensitic stainless iron is usually used for: blades, cutlery, surgical instruments, fasteners, etc.

There are many stainless steel manufacturers in China, but we are one of the best choices for you.

Other supplier products

|

|

316 Stainless Steel Sheet |

316 stainless steel sheet metal is a popular alloy, which contains molybdenum to enhance its corrosion resistance. This alloy is widely used in var... |

|

|

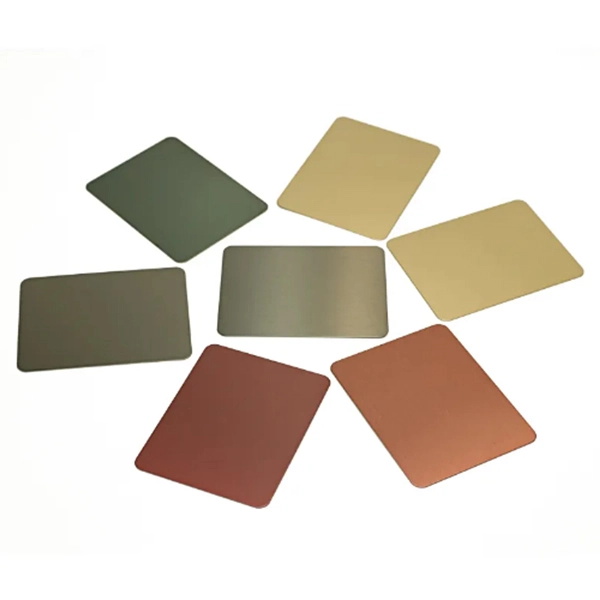

PVD Coated Stainless Steel Plate Sheet |

PVD (Physical Vapor Deposition) coated stainless steel plate sheet is achieved by depositing a thin layer of metal or compound on the stainless ste... |

|

|

Stainless Steel Materials |

Stainless steel materialsare widely used in various industries for their excellent corrosion resistance and durability. They are alloys of iron wit... |

|

|

Vibration Silver Plate Sheet Stainless Steel |

Vibration Silver Plate Sheet Stainless Steel has a textured surface with a silver color. This finish is achieved by using special brushes or roller... |

|

|

304 Stainless Steel Plate/Sheet |

Normandy Metal, your trusted 304 stainless steel plate suppliers. We offer high-quality 304 stainless sheet metal, known for its excellent corrosio... |

供应产品

Same products