Metal Roofing Tile Former

This series of metal tile roll forming machine is used to make metal roofing tiles. Mainly including a step-pressing system, our steel roofing machines can effectively press the metal panels formed by the roll forming system. As one of the mature glazed tile roll forming machine suppliers in China, Hangzhou Roll Forming Technology Co., Ltd. provides metal roof machine wholesale at reasonable prices. Feel free to contact us for more information.

Features and Advantages of Metal Roof Roll Forming Machine

This step tile roll forming machines series is for continuously roll forming and pressing step tiles sheets. The step length of these steel roofing machines can be set up and the depth of each step is adjustable.

The production speed of this series is about 8 m/min.

Similar to the color steel roll forming machine in stock, this metal roofing machine series also possess multiple patents under CE Certified and EUROPEAN quality standards.

Prompt delivery of this model is available.

Raw Material for Metal Roof Roll Forming Machine

Material type: Color coated Steel, Aluminum sheet

Thickness: 0.4-0.6(mm)

Yield Strength: 230-350MPa optional

Width: 1200/1220/1250(mm)

Production Line Components and Parameters of Metal Roof Roll Forming Machine

1. Decoiler 5t/8t/10t/15t Motor/hydraulic motor/passive (optional)

2. Filming covering device optional

3. Front shear optional

4. Lubricating device no need

5. Roll forming system individual standing column structure

6. Safety cover optional

7. Step pressing unit Step length, depth, head & end length is adjustable

8. Post cutting hydraulic

9. Output System Manual supporter/ Automatic Stacker (optional)

Stackmaster (Output direction) Lateral/Longitudinal (optional)

10. Hydraulic system Power supply for decoiler /post-cutting system

11. Electric control system MITSUBISH/ SIEMENSE/AMS (optional or as requested)

Working Flow of Metal Roof Roll Forming Machine

Similar to the high-speed roofing tile-making machine, the working flow of the metal roof panel machine also goes through the following stages:

Coil Charging Car (optional) - Decoiler (passive/auto) - Front Shear(optional) - Feeding and Guiding Table - Filming Covering (optional) - Roll Forming System

Application of Metal Roof Roll Forming Machine

Metal Roofing tiles is suitable for every architectural design and it is much more convenient and takes a shorter time for installation. The following pictures show you several cases of colored metal roofing tiles.

Glazed Tiles Uses

The exquisite colored steel glazed tiles not only preserve the shape of traditional terracotta tiles but also show an elegant beauty, rich and bright colors.

The material for these metal roof bending machines is light and with high strength. The weight of colored steel glazed tiles is only about one-tenth of that of traditional terracotta tiles, and the strength is also unparalleled.

The surface of the long colored steel glazed tile has been treated with anti-corrosion and anti-rust many times, and it is not easy to be easily oxidized, usually up to 30.

Water-proof color steel glazed tile slopes are seamlessly connected. The sealing performance is quite excellent, with other roof building materials unmatched.

Short construction time. The color steel glazed tiles are fast paved, the construction time is shortened, the price is relatively reduced, and there is no seasonal impact during construction.

Specification of Metal Roof Roll Forming Machine

Machine Condition Fully New, A Grade quality

Panel Shape As profile drawing and customer’s requirements

Operator needed 1-2 persons

Power Supply 220V/380V/415V/460V, 50/60Hz, 3P (as requests)

Equipment Weight About 15t

Dimension (L*W*H) about 25*3*2m

LOADING SIZE Normally need 1x 40' (+ 1x 20GP) container.

Equipment Color Normally Blue/White, or as requests;

Place of Origin Zhejiang, China (Mainland)

Packing Standard and careful export packing

As one of the most professional roll forming machine manufacturers, we provide steel tube forming machine, roll forming equipment, coil upender, pipe milling machineand etc. For metal roofing machine pricesor more, contact us.

在线联系供应商

Other supplier products

| HIGH SPEED TUBE MILL LINE | High Speed Tube MillLine is used to produce tube diameter between φ4mm to φ50mm. The top working speed of this tube mill linecan reach as h... | |

| Stainless Steel Tube Mill Line | STAINLESS STEEL TUBE MILL LINE Stainless still tube millLine is specially used for producing stainless steel straight seam welded pipe. It is ma... | |

| Guardrail roll forming machine | Hangzhou Roll Forming Technology Co., Ltd is a professional manufacturer and exporter of all kinds of standard and non-standard cold roll forming l... | |

| Rolling Shutter Door Roll Forming Machine | This series of rolling door machines are mainly used to make various rolling shutter door panels. Our rolling shutter slats roll forming machineis ... | |

| Flying Saw | Flying sawis an auxiliary equipment used in a continuous production line. Flying saw cutterautomatically fixed ruler cuts steel pipes. It is one of... |

Same products

| 9606 Angle Grinder Chamfering Stand | 卖方: 浙江石井工具有限公司 | 1. High compatibility; fits over 90% of models on the market. 2. Constructed primarily from alum... | |

| 3025 Manual Ceramic Cutting Machine | 卖方: 浙江石井工具有限公司 | The 3025 Manual Ceramic Cutting Machine is a versatile and reliable tool designed for precision c... | |

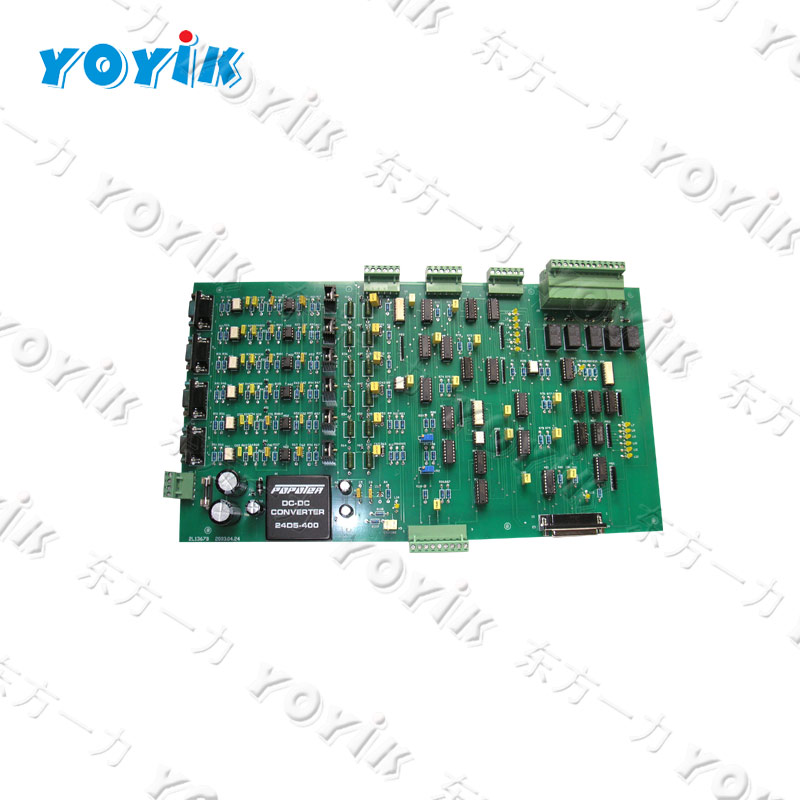

| China factory Open module ADAM-5056S for power station Sold by YOYIK | 卖方: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | China factory Open module ADAM-5056S for power station Sold by YOYIK. Deyang YOYIK is a professio... | |

| Manual Tile Cutting | 卖方: 浙江石井工具有限公司 | Manual tile cuttingis a skill that has been honed over centuries, a craft that requires patience,... | |

| Downspout Roll Forming Machine | 卖方: Zhejiang Jinggong Science & Technology Co., Ltd. | This downspout pipe roll forming machinecan produce the sealed color water pipes by forming the c... |