High Frequency Induction Heating Machine

The working frequency of CX series ultra high frequency induction heating machinecovers 50KHZ ~ 120KHZ. You can find the existence of this high frequency heating machineseries in induction welding, tool welding, pipe welding, thermal nesting, thermal packaging, etc.

Advantages of JKZ high frequency induction heating machine

Strict selection of high-quality components and optimized design scheme. After long-term use, the induction generator of JKZ high frequency induction heating equipmentcan still work stably and reliably.

A variety of remote control schemes can be selected, and this induction heating equipment can also allow you to control the working status of your high-frequency induction heating equipment through various signals such as on-off signals, 4-20mA, 0-10V, etc.

Equipped with a condition monitoring system (CMS), JKZ high power induction heater can alarm its users about possible equipment failures in real-time.

With a lightweight design scheme, it is convenient for customers to flexibly adjust the installation location of our high-frequency inverter for induction heating.

The induction coil of our high-frequency induction heating machine is simple to make and can be adapted to various workpieces of different shapes.

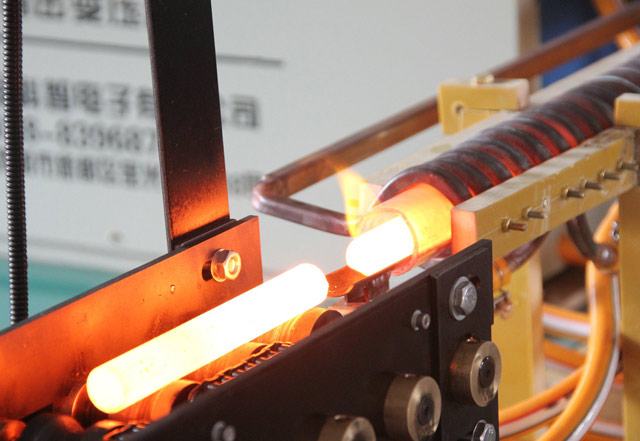

Principle Of High Frequency Induction Heating

The induction coil of the high-frequency induction heater will generate a powerful magnetic beam of polar instantaneous changes. When operating a high-frequency heater, the metal that requires heat treatment will be placed in the high-frequency coil, and the magnetic beam mentioned above will penetrate the entire ready-to-be-heated metal object. The corresponding powerful eddy current will then be generated. Since there is a resistor in the metal, strong jeophenia will then be generated and cause the temperature of the inductive heating material to rise rapidly, thereby achieving heat treatment.

High Frequency Induction Heating Is Used For?

The main applicable industry range of the high-frequency induction heating machine mainly includes high-frequency wave induction, high-frequency sensing heat treatment, high-tech wave induction metal smelting, etc.

High-frequency induction heating is a process that uses an electromagnetic field to generate heat in a metal object. It is used in various industrial applications, including:

Brazing and soldering: Induction heating is used to join two metal parts by melting a filler material between them.

Heat treatment: Induction heating can be used to harden, soften, or temper metals, improving their mechanical properties.

Melting and casting: Induction furnaces can melt and cast metals, such as steel, copper, and aluminum.

Welding: Induction welding is a non-contact method of joining two metal parts by heating them to a temperature where they fuse together.

Annealing: Induction annealing is a process that heats a metal to a specific temperature and then cools it slowly, making it more ductile and easier to work with.

Surface hardening: Induction heating can be used to selectively harden the surface of a metal object, making it more wear-resistant.

Shrink fitting: Induction heating can be used to expand a metal object and then quickly cool it, causing it to contract and fit tightly onto another part.

JKZ is a professional induction heater manufacturer, we provide induction heating power supply, induction heating unit, high frequency heat treatment, induction heating generator, induction heater china, etc. Contact us to want to know principle of high frequency induction heatingor buy induction heatingproducts.

在线联系供应商

Other supplier products

| Induction Preheating | JKZ,induction heating power supply,can provide you a complete induction heating equipment experience service. Our service staff will give customers... | |

| Induction Annealing And Normalizing | Induction annealingand induction tempering are very important processes in the heat treatment of the metal workpiece. These two processes can effec... | |

| Ultrasonic Frequency Induction Heating Machine | SWS series ultrasonic heating machinehas a very wide application field. It can be used in automobile and motorcycle parts production, metal hot for... | |

| Induction Shrink Fitting | JKZcan provide you a complete induction heating machine chinaexperience service. Our service staff will give customers a full response immediately,... | |

| Induction Heating Machines In Automotive Industry | The automobile manufacturing industry is the most typical and core application field of JKZ induction heating equipment. Situations like shafts sur... |