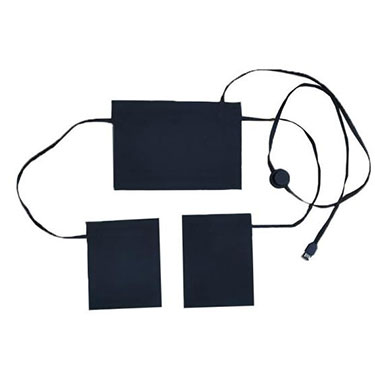

Battery Cold Plate

The main materials of battery cooling platesare aluminium alloy and stainless steel. Due to the requirements of low density and various forming processes, aluminium alloy can meet the lightweight requirements of the application end. At present, there are two process schemes for battery cold plate: integral casting and aluminium profile welding. And the technique of FSW is favored by more and more new energy automobile OEMs at home and abroad.

FSW welding has been widely used in the manufacture of EV battery cooling plate and EV battery tray FSW because of its non-melting, automation, intelligence, environment-friendly and integrated characteristics.

As one of the leading friction stir welding suppliers, Cheeven provide cooling photovoltaic panels, water cooling solar panels, battery cold plate, battery tray, etc. For more information, please feel free to contact us!

在线联系供应商

Other supplier products

| Convection Panel Heater | Cheeven has wall-mounted eco convection panel heaterwhich have functions such as power switches, electronic control / remote control, and black/whi... | |

| Carbon Nanotubes Membrane | The CNT carbon nanotubes membranewill undergo a high single-walled carbon nanotube preparation process, which gives itself excellent and stable opt... | |

| Electric Heating Radiator | As top of electric radiator manufacturersin China, Cheeven provides types of electric radiators. Efficient wall mounted electric heaterscan be used... | |

| Copper Water Cooling Plate | Copper and its alloys are often used for metal cooling plates as heat dissipation materials because of their excellent thermal conductivity. Alumin... | |

| Aluminum Alloy Wheel Welding | The main materials of the automobile hub are aluminium alloy and stainless steel. Aluminum wheel weldingis favored by more and more automobile main... |