板式给料机

Introduction

transporting raw material to the crushing plant, where their combination of reliability and robustness have proven to give many years of trouble free operation with minimal maintenance.

Features

Plate Feeder is noted for its smooth reciprocating action providing a uniform feed rate. The feed rate is varied by changing the eccentric throw on select models.

Application

Plate Feeder is ideal for sand, gravel, and recycle applications or in portable plants where the rugged durability of the feeder aides in the crusher discharge. The Universal Engineering Reciprocating Plate Feeder is built in a range of sizes and types for shovel or dragline loading, ramp loading, or bulldozing to trap. It is available in varying widths and lengths to fit your specific application.

Working principle

The working process is divided into two parts: firstly, the dynamic is produced by motor and transited to connecting rod and ratchet wheel by reducer. Secondly, the dynamic prompts the connecting rod of eccentric device to reciprocate. The dynamic also prompts pawl and ratchet wheel to make driving sprocket rotate so that link plate intermittently moves. As a result, minerals are conveyed.

Technical parameters

model Chain plate Feeding particle size(mm) Production

capacity(m3/h) motor weight(kg)

width(mm) Center

distance of sprocket(mm) Speed(m/s) Model power

GBZ120-4.5 1200 4500 0.05 ≤500 100 Y160L-4 15 31279

GBZ120-5 5000 33427

GBZ120-5.6 5600 34321

GBZ120-6 6000 35900

GBZ120-8 8000 Y180L-4 22 41342

GBZ120-8.7 8700 43164

GBZ120-10 10000 46962

GBZ120-12 12000 51844

GBZ120-15 15000 Y200L-4 30 62157

GBZ150-4 1500 4000 ≤600 150 Y160L-4 15 33197

GBZ150-6 6000 Y180L-4 22 39257

GBZ150-7 7000 43352

GBZ150-8 8000 45962

GBZ150-9 9000 Y200L-4 30 50522

GBZ150-12 12000 Y225M-4 45 59915

GBZ180-8 1800 8000 ≤800 240 Y225M-4 45 51360

GBZ180-9.5 9500 57397

GBZ180-10 10000 59632

GBZ180-12 12000 66029

GBZ240-4 2400 4000 ≤1000 400 Y200L-4 30 44780

GBZ240-5 5000 50737

GBZ240-5.6 5600 52447

GBZ240-10 10000 Y225M-4 45 76373

GBZ240-12 12000 85331

在线联系供应商

Other supplier products

| 干式磁选机 | 永磁粉筒式干式磁选机是鑫海矿山机械集团专业打造的干式磁选机产品,鑫海永磁粉筒式干式磁选机性能质量高,采用干式磁选,适用粒度范围7~10mm。目前鑫海永磁粉筒式干式磁选机在众多矿山工程中得到应用,以其出色的性能在业界享受盛誉。想了解更多的鑫海永磁粉筒式干式磁选机产品技术参数以及鑫海永磁粉筒式干式... | |

| 全自动絮凝剂制备系统 | 全自动絮凝剂制备系统是鑫海矿山机械集团专业打造的自控设备之一,鑫海全自动絮凝剂制备系统采用PLC、变频器和液位控制器等元件,根据控制要求编制控制程序,具有运行指示和故障报警功能,可以实现全自动运行和设备故障时紧急停止。鑫海全自动絮凝剂制备系统采用国际高端技术,在市场上深受中外客户的欢迎。欢迎点... | |

| 橡胶渣浆泵 | XPA(2) 型橡胶渣浆泵 — 产品概述XPA(2)型橡胶渣浆泵是鑫海矿山机械集团自主研发的高效、功耗低、质量优良、耐腐蚀、耐磨的新型橡胶渣浆泵产品,XPA(2)型橡胶渣浆泵耐腐耐磨,抗冲击能力较强,可广泛适用于矿山、冶金、电力、煤炭、化工、建材等行业的输送作业。欢迎点击在线咨询按... | |

| 鑫海耐磨橡胶 | 烟台鑫海耐磨橡胶筛网以鑫海自主研发的超级耐磨橡胶原料为材料,耐腐蚀、抗冲击、抗撕裂、噪音低等优点。较常规胶网几个月就要更换的周期来看鑫海耐磨胶网大大的节约了耗材,减少了浪费。想了解更多的鑫海耐磨橡胶筛网产品技术参数以及鑫海耐磨橡胶筛网价格等详细信息,请点击在线咨询按钮,与鑫海矿山机械集团进行交... | |

| 双叶轮浸出搅拌槽 | 烟台鑫海生产的双叶轮浸出搅拌槽是一种平稳节能、结构紧凑。使用叶轮作为内衬橡胶、维修方便的浸出作业设备,鑫海双叶轮浸出搅拌槽常用作黄金氰化厂搅拌浸出及碳吸附用,也可用于冶金、化工、轻工部门相应条件下的混合搅拌浸出作业。想了解更多的鑫海双叶轮浸出搅拌槽设备产品技术参数以及鑫海双叶轮浸出搅拌槽价格等... |

Same products

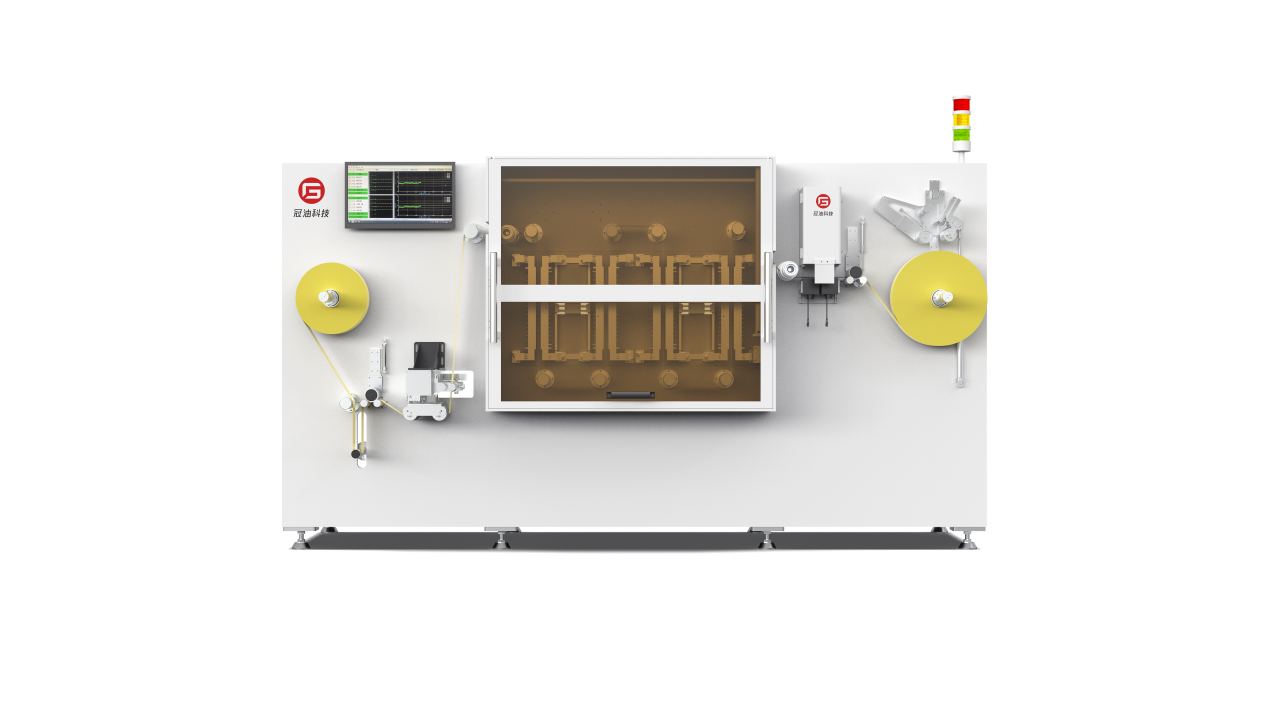

| 单工位静电打孔机 | 卖方: 武汉冠油科技有限公司 | 单工位静电打孔机是一款专业应用于国内外香烟接装纸生产厂家和卷烟生产行业的接装纸静电打孔机,具有独立知识产权。相比激光打孔机,静电打孔在实现高透气度的同时,能保持稳定性,避免激光打孔时孔径过大导致... | |

| YZH WHEN1500固定式液压机械臂 | 卖方: 山东伊润基础工程有限公司 | 以下是YZH WHEN1500固定式液压拆除臂的详细介绍,包括其特点、优点和案例研究:YZH WHEN1510固定式底座碎石机臂的特点:智能多模式控制:支持驾驶室操作、无线/有线远程控制、光纤+... | |

| YZH WHEN1410固定式底座碎石机 | 卖方: 山东伊润基础工程有限公司 | YZH WHEN1410固定式底座碎石机是一种专为采矿、冶金及相关行业大型物料的二次破碎而设计的专用设备。通过更换附件(如液压锤或莲花爪),它可以执行多种功能,包括破碎、抓取和拆除。 WHEN... | |

| JY-160S2 Standard Plastic Injection Machine | 卖方: Dongguan Jieyang Machinery Co., Ltd | Straight screw ejected assembly. Two(three)-phase temperature, ejected speed, backing pressure a... | |

| WPC 木塑室外地板挤出生产线 | 卖方: Qingdao Trusty Plastic Machinery Co.,Ltd | 木塑复合材料(WPC)与木材不同,具有更高的耐腐蚀性和耐温性。其低残余湿度和多孔结构也赋予了它更高的强度。凭借这一特性,WPC地板(或甲板)被广泛应用于各种休闲场所的建造,如夏季咖啡馆、凉亭和门... |