Pharmaceutical Water System

Pharmaceutical Water Systems

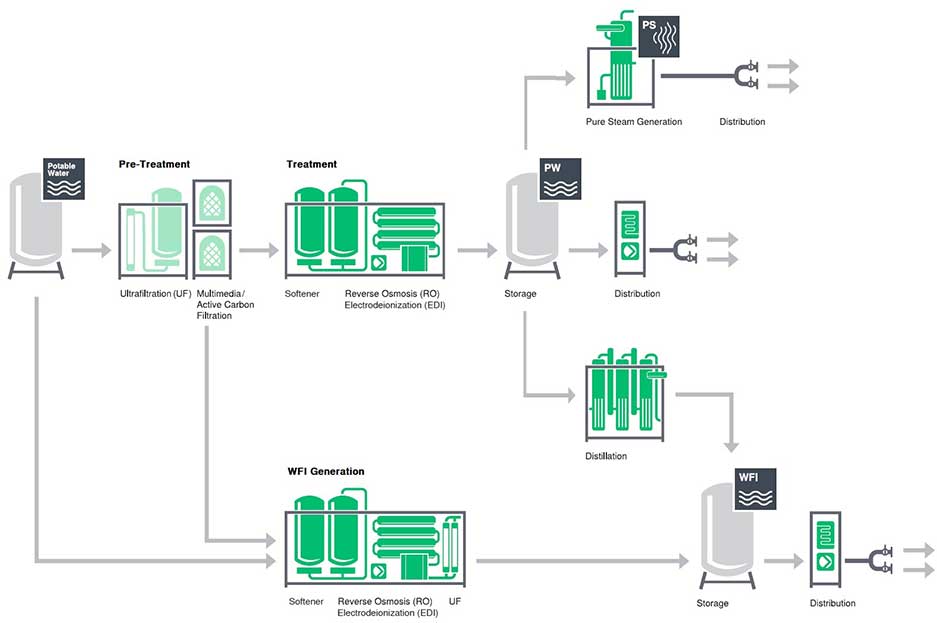

Water is the most widely used process raw material in the pharmaceutical industry, which is used as the composition, solvent and diluent of drugs. Pharmaceutical water is mainly divided into two categories:

Purified water: it is pharmaceutical water prepared from raw water by distillation, ion exchange, reverse osmosis or other appropriate methods, and does not contain any additives.

Water for injection: It is the water obtained by taking purified water as raw water, distilling in a specially designed distiller, condensing and cooling. Sterile Water for Injection is the water prepared according to the injection production process.

The purified water system in pharmaceuticalis composed of water treatment equipment and transportation system. Through design, installation and confirmation, judge and evaluate whether the equipment meets the predetermined production capacity, water quality standard, capacity, flow rate, pressure, temperature, disinfection method, etc.

The operation and maintenance of water system in pharmacompany shall be monitored and managed according to the requirements of verification and documents. Ensure that the operating parameters of the system are within the range of operating parameters confirmed by the equipment.

TYPES OF BIOCELL PHARMACEUTICAL WATER SYSTEMS

Pharmaceutical Water Purification System

Water For Injection System (WFI)

Pure Steam Generation System(PS/CS)

Purified Water System(PW)

PW/WFI Storage & Distribution Systems

Pharma Water System Control & SCADA

Sanitary Heat Exchanger

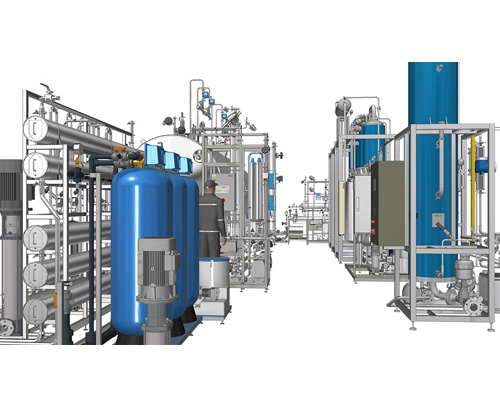

Pharmaceutical Water Purification System

The pharmaceutical water system is composed of water treatment equipment and transportation system. Through design, installation and confirmation, judge and evaluate whether the equipment meets the predetermined production capacity, water quality standard, capacity, flow rate, pressure, temperature, disinfection method, etc.

Ultrapure Water System

Ultrapure water is produced by distillation, deionization, reverse osmosis technology or other appropriate supercritical fine technology. Now ultrapure water has been widely used in biology, medicine, industrial manufacturing and other fields. Ultrapure water system refers to the production system in which raw water and ultrapure water are completely produced. The conductivity of common tap water is less than 10-20 after being treated by the primary reverse osmosis system μ S/cm, permeate conductivity1-5 after secondary reverse osmosis system μ S/cm is even lower. The reverse osmosis system can be supplemented with ion exchange equipment or EDI equipment to prepare ultrapure water, making the resistivity as high as 18.25 megohm. cm.

GOOD DESIGN PRINCIPLES OF BIOCELL PHARMACEUTICAL WATER SYSTEM

01

Customization

Comprehensively understand the customer's actual needs for water preparation process, system configuration, etc., and customize the water system.

02

Cooperation

BIOCELL is a member of China Pharmaceutical Equipment Industry Association, and has long maintained technical exchanges and cooperation with many well-known domestic pharmaceutical enterprises.

03

Experienced

BIOCELL has a group of industry senior experts, professional designers and experienced project installers who have practiced in many application fields for many years, with an average working time of more than 10 years.

在线联系供应商

Other supplier products

| Automatic Cappuccino Machine for Home Use | EDI is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration techn... | |

| PURE STEAM GENERATOR | PURE STEAM GENERATORS A pure steam generatoris one of the important equipment used for tank equipment, pipeline system, and filter disinfection, a... | |

| WATER PRE-TREATMENT | Based on the quality of different raw water, we are committed to providing customers with customized solutions. Modular design is adopted, with rea... | |

| Pharmaceutical Water Purification System | The operation and maintenance of equipment shall be monitored and managed according to the requirements of verification and documents. Ensure that ... | |

| PW/WFI Storage & Distribution Systems | The purified water generation and distribution systemis the core unit of the whole pharmaceutical water system, and its main function is to ensure ... |

Same products

| 拓纷生物制药冻干机 TF-LYO-2 | 卖方: 上海拓纷机械设备有限公司 | LYO生物制药冷冻干燥机采用标准化制造工艺生产,降低制造成本,缩短生产周期,同时确保性能和可靠性。冷冻干燥机的设计优先考虑安全性、多功能性、可靠性和长使用寿命,同时也确保用户和环境的安全。该设计... | |

| TOFFON冷冻干燥机TF-LYO-0.5冻干机 | 卖方: 上海拓纷机械设备有限公司 | LYO 生物制品冷冻干燥机是一种用于生物制药的专用机器,用于保存和储存蛋白质和疫苗等生物制品。它通过在低温下冷冻生物物质,然后在真空环境中除去水分,从而获得稳定,长期干燥的产品来实现这一目标。该... | |

| PHARMACEUTICAL REVERSE OSMOSIS SYSTEM | 卖方: Nanjing Biocell Environmental Technology Co., Ltd | PHARMACEUTICAL REVERSE OSMOSIS SYSTEM With RO membrane separation technology as the core, the re... | |

| SANITARY HEAT EXCHANGER | 卖方: Nanjing Biocell Environmental Technology Co., Ltd | SANITARY HEAT EXCHANGER The wfi sanitary heat exchanger(sterile double tube plate heat exchanger... | |

| CLEAN STEAM GENERATOR | 卖方: Nanjing Biocell Environmental Technology Co., Ltd | CLEAN STEAM GENERATORS The prototype of the clean steam generatorfor humidification is a pure st... |