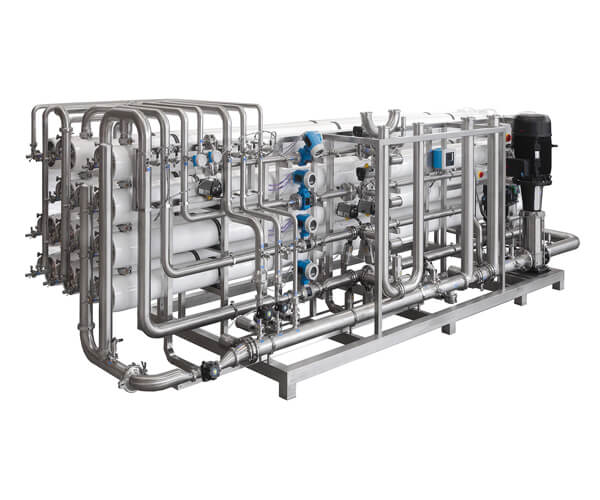

REVERSE OSMOSIS PLANT

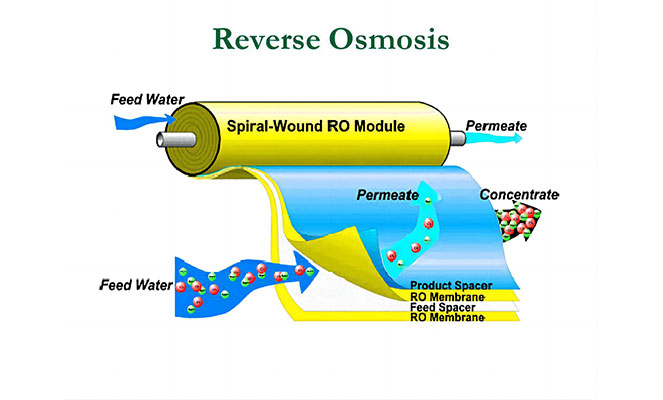

Separate the pure water from the solution containing solute with a semi permeable membrane that can only pass through water. At this time, the water on the pure water side will spontaneously pass through the semi permeable membrane and enter the solution side. The water surface on the solution side will rise. This phenomenon is penetration. When the liquid level rises to a certain height, the pressure on both sides of the membrane reaches equilibrium, and the liquid level on the solution side no longer rises. At this time, there is a pressure difference on both sides of the membrane, which is called osmotic pressure. If a pressure greater than the osmotic pressure is applied to the solution side, the water molecules in the solution will be squeezed to the pure water side. This process is just the opposite of osmosis, which is called reverse osmosis (RO). We can see from the process of reverse osmosis that due to the pressure, the water molecules in the solution enter the pure water, the amount of pure water increases, and the solution itself is concentrated.

Technical Data of Reverse Osmosis Plant

|

Item |

Reference value |

|

Comprehensive desalination rate |

>97~99% |

|

Intercepted molecular weight of organic matter |

>150MW |

|

Bacterial elimination rate |

>99% |

|

Pyrogen elimination rate |

>99% |

|

Silica removal rate |

>98.5% |

|

Removal rate of heavy metal ions |

>96~99% |

Primary Reverse Osmosis Unit

|

Item Type |

Water output (m3/h) |

Minimum water intake (m3/h) |

Desalination rate (%) |

Temperature of the working water (℃) |

|

FSJ41X-0.5XB |

2 |

98 |

5-35 |

|

|

FSJ42X-1XB |

1 |

98 |

5-35 |

|

|

FSJ42R-2XB |

2 |

97 |

5-35 |

|

|

FSJ43R -3XB |

3 |

97 |

5-35 |

|

|

FSJ43R-4XB |

4 |

97 |

5-35 |

|

|

FSJ82R-6XB |

6 |

97 |

5-35 |

|

|

FSJ82R-8XB |

8 |

13 |

97 |

5-35 |

|

FSJ83R-10XB |

10 |

15 |

97 |

5-35 |

|

FSJ83R-15GB |

15 |

20 |

97 |

5-35 |

|

FSJ84R-20GB |

20 |

26 |

97 |

5-35 |

|

FSJ85R-25GB |

25 |

35 |

97 |

5-35 |

|

FSJ86R-30G |

30 |

40 |

97 |

5-35 |

|

FSJ86R-50G |

50 |

67 |

97 |

5-35 |

Secondary Reverse Osmosis Unit

|

Item Type |

Water output (m3/h) |

Minimum water intake (m3/h) |

Desalination rate (%) |

Temperature of the working water (℃) |

|

FSJ41X-0.5XB-2 |

98 |

5-35 |

||

|

FSJ42X-1XB-2 |

1 |

98 |

5-35 |

|

|

FSJ42R-2XB-2 |

2 |

97 |

5-35 |

|

|

FSJ43R -3XB-2 |

3 |

97 |

5-35 |

|

|

FSJ43R-4XB-2 |

4 |

97 |

5-35 |

|

|

FSJ82R-6XB-2 |

6 |

97 |

5-35 |

|

|

FSJ82R-8XB-2 |

8 |

15 |

97 |

5-35 |

|

FSJ83R-10XB-2 |

10 |

15 |

97 |

5-35 |

|

FSJ83R-15GB-2 |

15 |

31 |

97 |

5-35 |

|

FSJ84R-20GB-2 |

20 |

38 |

97 |

5-35 |

|

FSJ85R-25GB-2 |

25 |

97 |

5-35 |

|

|

FSJ86R-30G-2 |

30 |

97 |

5-35 |

|

|

FSJ86R-50G-2 |

50 |

97 |

5-35 |

Introduction of Reverse Osmosis Plant

The reverse osmosis membrane used by the reverse osmosis equipment is a semi permeable spiral roll membrane. When the raw water is sent to the reverse osmosis membrane at a certain pressure, the water passes through the micro aperture on the membrane and is collected to obtain pure water. The impurities in the water, such as soluble solids, organic substances, colloidal substances and bacteria, are intercepted by the reverse osmosis membrane, concentrated in the intercepted solution and removed. Single stage reverse osmosis can remove more than 97% of the dissolved solids in the raw water, and double stage reverse osmosis can remove more than 99% of the dissolved solids, more than 99% of the organic matter and colloid, and almost 100% of the bacteria. The two-stage reverse osmosis equipment uses the first stage pure water to enter the second stage as raw water, which can make the pure water produced reach higher quality. It is suitable for the needs of high-purity water production, and can also be used in situations where the raw water conductivity is high.

At present, reverse osmosis equipment is one of the most advanced water treatment equipment in the world. With low operating cost, economy, convenient operation and reliable operation, it is the first choice for businesses to produce pure water. The production capacity of the equipment is the value under 25 ℃ raw water and standard production conditions. Changes in

water temperature and production conditions will affect the production capacity of the equipment.

There are many reverse osmosis plant manufacturers, but we are one of the best choices for you.

For more informationabout reverse osmosis plant costand purified water system in pharmaceutical, please feel free to contact us!

在线联系供应商

Other supplier products

| Water System for Pharmaceutical Use | Water System for Pharmaceutical Use In the pharmaceutical industry, Biocell provides professional solutions for purified water system, water for i... | |

| Water For Injection (WFI) Generation System | Biocell wfi water systemadopts an advanced three-stage separation WFI generation process of steam and water, and the quality of produced water meet... | |

| PURE STEAM GENERATOR | A pure steam generator is one of the important equipment used for tank equipment, pipeline system, and filter disinfection, and pure steam generato... | |

| Water System for Pharmaceutical Use | Water System for Pharmaceutical Use In the pharmaceutical industry, Biocell provides professional solutions for purified water system, water for i... | |

| ELECTRIC CLEAN STEAM GENERATOR | Clean steam generator using electric energy as heating source is referred to as electric heating clean steam generator. The steam generated after t... |

Same products

| 拓纷生物制药冻干机 TF-LYO-2 | 卖方: 上海拓纷机械设备有限公司 | LYO生物制药冷冻干燥机采用标准化制造工艺生产,降低制造成本,缩短生产周期,同时确保性能和可靠性。冷冻干燥机的设计优先考虑安全性、多功能性、可靠性和长使用寿命,同时也确保用户和环境的安全。该设计... | |

| TOFFON冷冻干燥机TF-LYO-0.5冻干机 | 卖方: 上海拓纷机械设备有限公司 | LYO 生物制品冷冻干燥机是一种用于生物制药的专用机器,用于保存和储存蛋白质和疫苗等生物制品。它通过在低温下冷冻生物物质,然后在真空环境中除去水分,从而获得稳定,长期干燥的产品来实现这一目标。该... | |

| PHARMACEUTICAL REVERSE OSMOSIS SYSTEM | 卖方: Nanjing Biocell Environmental Technology Co., Ltd | PHARMACEUTICAL REVERSE OSMOSIS SYSTEM With RO membrane separation technology as the core, the re... | |

| SANITARY HEAT EXCHANGER | 卖方: Nanjing Biocell Environmental Technology Co., Ltd | SANITARY HEAT EXCHANGER The wfi sanitary heat exchanger(sterile double tube plate heat exchanger... | |

| CLEAN STEAM GENERATOR | 卖方: Nanjing Biocell Environmental Technology Co., Ltd | CLEAN STEAM GENERATORS The prototype of the clean steam generatorfor humidification is a pure st... |