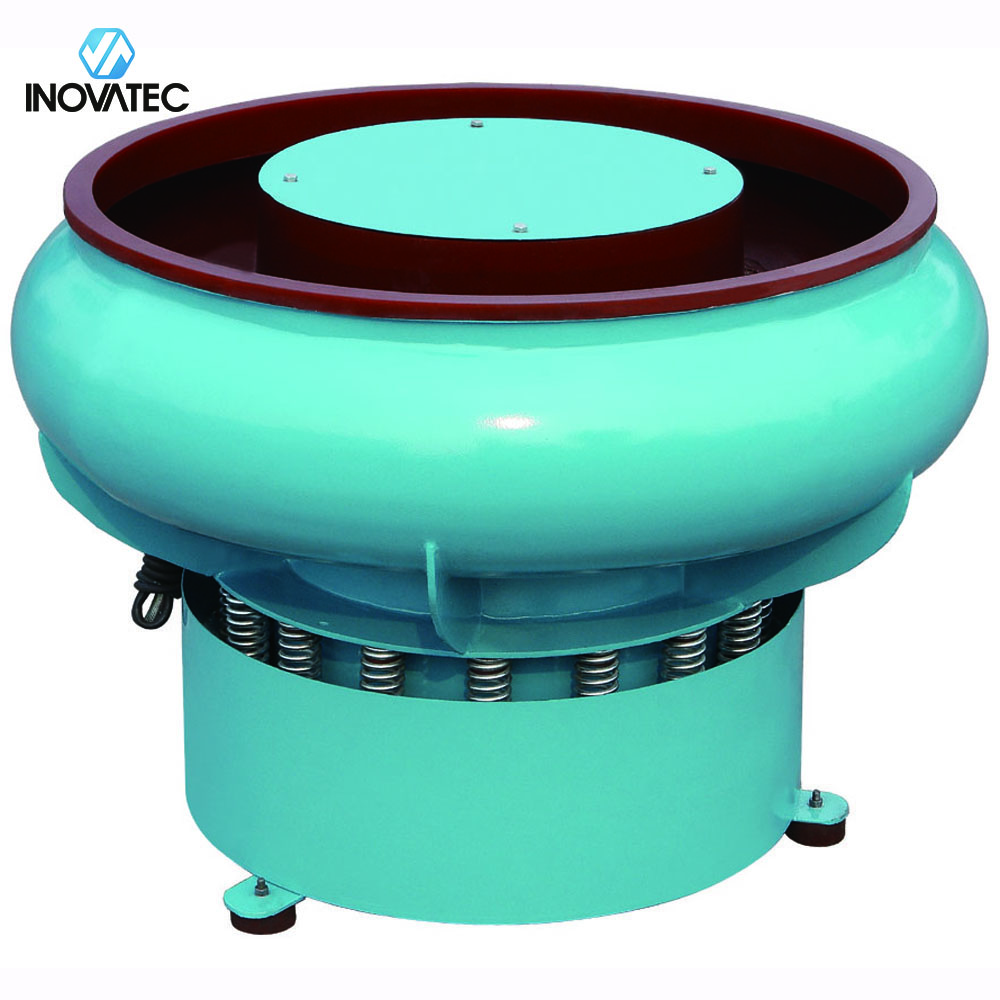

Vibratory dryer with heating element – Vibratory drier

FUNCTIONAL PRINCIPLE

The vibratory dryer generate gentle movement of parts through corn cob or maize During vibratory moisture on surface of parts absorbed by media and heating The relative movement of parts and corn cob give parts surface also shinning effect

TECHNICAL FEATURES

– Helically shaped work channel without built-in rampallows gentle component movement. – Optional PU lining or Polyurethan lining design for both structure – Temperature adjustable accoding to practical requirement – Separation seive integrated in machine for continuous processing

SPECIAL EQUIPMENT

– Optional Pneumatic level shetter – Optional cust cover and sound proof cover – For drying exremely delicate or high value added component, machine can be incoporated with poluurethane material which protect parts, the machine available with hot blasting air

– Optional with hot air only and without any media

在线联系供应商

Other supplier products

| Ceramic deburring media – RMB/D1 polishing abrasive | RMB/D1 ceramic grinding media is produced by mixing porcelain, kaolin,clay, river clay together with brown alumina oxide abrasives. The wet materi... | |

| Crankshaft Polishing machine | Applications: Applied to all kinds of shafts,poles,covers parts surface treatment.Polishing,grinding,rounding and deburring without change parts o... | |

| Vibratory finishing machine for Roto finish | Standard Features: Easy to change the separation deck Heavy-duty long service vibration motor Optional VFD (Variable Frequency Drive to control mo... | |

| Vibratory Deburring Machine Tumbler for ball burnishing process | Standard Features: Effective motor position for Excellent Vibration. High tensile bolts and nuts for long service life of motor and machinery. Eff... | |

| Longitudinal vibratory finishing machine – Continuous | Introduction Recently with increasing cost of manual polishing process and high requirement of automation, continuous linear vibratory finishing... |