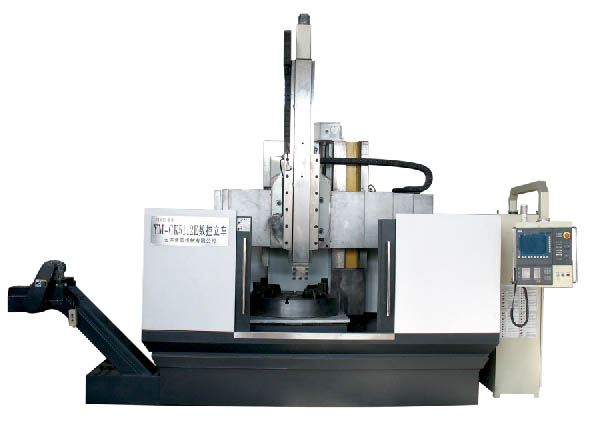

YM-CKG125 CNC High speed Vertical Turning lathe

YM-CKG125 CNC High speed Vertical Turning lathe1. This system machine tool applies to cutting such tools as cemented carbide and ceramics to make rough, semi-fine processing and fine processing for internal and external cylindrical surface, conical surface, end face, cutting groove, screw and surface of revolution, etc. of ferrous metal, non ferrous metal and some nonmetal parts.2. There are three specifications available such as high-speed type, standard type, and heavy-load type.3. High-speed cutting: the maximum cutting speed is up to 2000m/min. The fast moving speed of the tool holder (horizontal and vertical) is up to 12m/min.4. The main transmission is driven by AC main shaft servo motor. Two-step variable speed uses the imported ZF gearbox. High-speed rotary work pieces are carried out with static and dynamic balance. High-precision transmission gears and gear grinding process are used to realize high transmission efficiency, low noise and reliable and stable operation under high speed.5. The feed system is driven by AC servo motor and the motor carries out direct linkage with ball screw by soft coupling to realize non-transmission clearance with high-precision operation.6. The column is in type of thermal symmetry and it is installed in the base of working platform. By the calculation of finite elements of the computer, effective vibration isolation measures are adopted with the features of high stiffness and high anti-vibration capacity.7. The working platform is in type of thermal symmetry and the main shaft adopts double short and circular column roller bearing center with high-precision and adjustable radial clearance while the axial direction utilizes large thrust sphere bearing with high-precision as the rolling guide and then the cooling device of oil temperature is equipped with, thus, the working platform is featured with high rotation precision, large bearing capacity and small thermal deformation.8. The feed motion of tool holder and ram adopts straight line bidirectional roller rolling guide to make the motion of tool holder own stable motion, high transmission efficiency and excellent precision retentively.9. CNC system adopts Siemens or FANUC system or other systems appointed by the user.10. The machine tool is equipped with chip removal device and semi-closed hood.11. Upon the demands of the users, tool magazine, butted-knife installation within the machine, boring-milling function, function of indexing and feed of working platform, grinding function, left vertical tool holder as well as full-closed-loop control etc. can be offered.12. Therefore, the electric components, hydraulic components and the functional parts all select international famous high-grade brand.

在线联系供应商

Other supplier products

| YM-CK5116Epro Semi-closed CNC Single Column Vertical Lathe | YM-CK5116Epro Semi-closed CNC Single Column Vertical Lathe 1. The product is in Pro version with professional design, being an improved product wit... | |

| YM-CK5123Epro CNC Single-ColumnYM-CK5123Epro CNC Single-Column vertical lathe vertical lathe | YM-CK5123Epro CNC vertical lathe for sale 1. The product is in Pro version with professional design, being an improved product with a huge market s... | |

| C5228E Double-column Vertical Lathe | C5228E Double-column Vertical Lathe 1. Modularization design and the general products are mature, stable and reliable. 2. Excellent casting (HT300)... | |

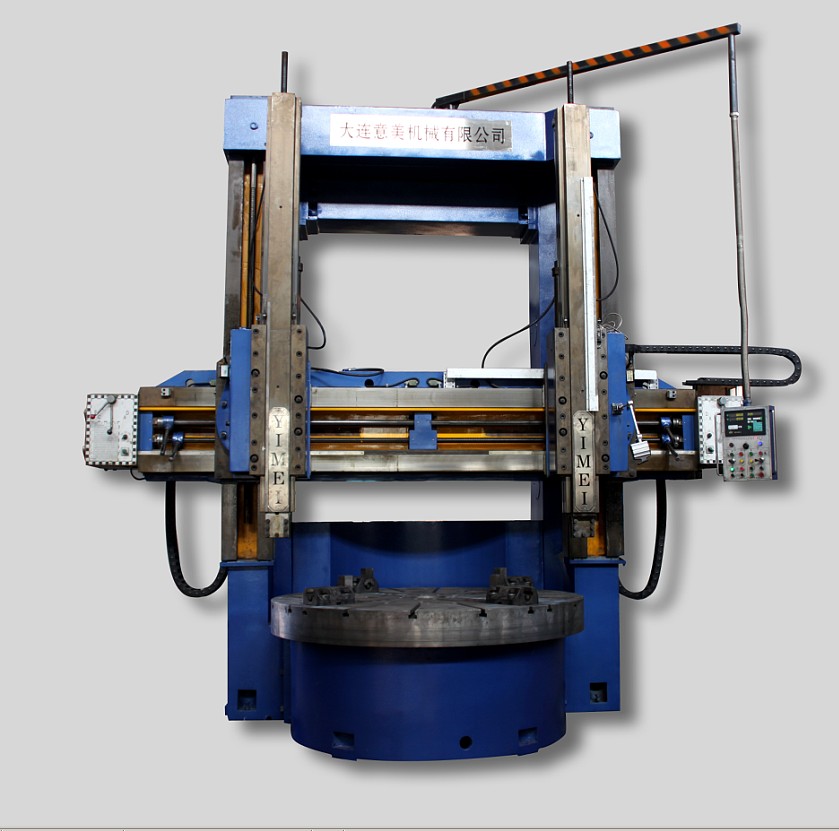

| Double Column Double Column Vertical LatheVertical Lathe | Double Column Vertical Lathe 1.The super-high quality and mass remarkably surpass the domestic first-class factories. 2.The beam guide and ram guid... | |

| CXK320 CNC vertical turning and milling center | CXK320 CNC vertical turning and milling center 1. CXK series CNC vertical turning and milling center was developed by our company independently. T... |