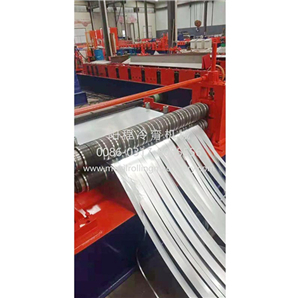

YC Automatic 1.25M-1.5MM Steel Coil Slitting Line

Automatic Slitting Line

SPECIFICATIONS

Hydraulic decoiler with coil car→feeding platform→leveling system→slitting system→scrap winding system→tension stand→hydraulic recoiler with coil car, PLC computer control system, hydraulic system, electric motors

SURFACE TREATMENT

1). Processing material: steel strip, coil tensile strength 280Mpa-550Mpa

2).Thickness of coiled plate: 0.3-1.5mm

3).Width of coiled plate: within 1250mm

4). Precision of slitting width tolerance: ±0.05mm

5). Line speed: 15-30m/min

6). Loading capacity of de-coiler machine(feeding machine): 7T

7). Loading capacity of re-coiler machine(receiving machine): 7T

8). Coil I.D: 450-550mm

9). Coil O.D: 1250mm

10). Knife pivot diameter of slitting: 145mm

11).Slitting blade 200×145×10

12).Number of blades: 18 sets

13).Material of slitting blade: Cr12MOV

14).Hardness of blade: HRC58°—60°

15).Recoiler I.D :508mm;

16). Power: 380V/50Hz/3Ph (or as per your request)

TECHNOLOGY

(1) Hydraulic coil Car

◆The car can move levelly and vertically, which is convenient for putting the steel coils to the un-coiler.

◆It is driven vertically by hydraulic cylinder with 4 guide pillars.

◆The level movement is driven by hydraulic motor.

(2) 7T Hydraulic de-coiler (4KW)

◆supporting steel rolls and uncoiling

◆the movable structure of double way hydraulic top tight

◆hydraulic pressure drives the level and landscape orientation movement

(3). (11KW)

◆Drive system consists of drive stand, decelerator, 11KW motor, the gear distribution box, coupler, connection shafts and cover.

◆Main section is made up of base, fixed brackets, large slide block, 2 blade pivot, movable brackets, slide block, the adjustment device of front and back of the brackets and the lifting device of blade pivot, supporting blades, isolating cover and rubber ring, etc.

◆the main section adopts manually move out the brackets which is very convenient to change the blades

(4). Scrap Winder (3KWx2)

◆It consists of base, the shaft and plate of edge material, friction wheel, supporting wheel chain, chain, decelerator and 3KWx2 electric machine.

(5). Tension stand

◆consist of base, pre-dividing shaft, bracket, press shaft, hydraulic damp device and hydraulic shaft lifting the press down device

(6). 7T Hydraulic recoiler (4KW)

◆It is consist of base, bearing frame, recoiler shaft, the expansion device of hydraulic recoiling, the expanded recoiling plate, movable arm bearing, supporting decelerator and motor.

(7). Hydraulic unload car

◆the car can carry the dividing coils and lift up and down and is movable

(8). Electrical control system:

◆including the complete wire to installation as well as the electrical box to operate the whole lines

(9). Hydraulic System

◆the hydraulic stand, pipes and the connect part

SALES TERMS

1). Machine Price: Please contact us, we will try to give you good discount for starting our cooperation

2). Payment term: 30%TT should be paid as advance deposit, 70%TT before shipment

Or 100% LC at sight

3). Package: naked with simple plastic film and loaded in one 20-feet container

4). Delivery time: 50 working days after receipt of the deposit

5). Guarantee: 12 months. If any part of machine breaks, we will supply it for free.

6). After sales service

This is maintained free of charge for 12 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians traveling abroad, and pay 100USDdayperson.

在线联系供应商

Other supplier products

| Ceiling CD60x27 and UD28x27 Profiles Double Line Roll Forming Machine | Ceiling CD60x27 and UD28x27 Profiles SURFACE TREATMENT 1) Processing material: steel strip 2) Material thickness: 0.3-0.7mm 3) Formed sizes on on... | |

| 4MM-3200MM CNC Cutting Machine | Parameters 1) Max cutting thickness: 4mm 2) Max cutting width: 3200m 3) Cutting angle: 1.5° 4) Intensity of sheared material: 450N/m㎡ 5) Dist... | |

| Wall Angle Roll Forming Machine | Study the the complex steel profile output from our steel rolling machine succeeded.Below is a short list of the applications and products produced... | |

| Metal Omega Profile Roll Forming Machine | We also can design the machine strictly according to your required profile. SURFACE TREATMENT 1) Processing material: 150mm width steel strip 2) M... | |

| EPS&Rock Wool Insulated Sandwich Panel Production Line | We also can design the as per your required profile drawing SPECIFICATIONS Composite De-coiler(4 sets)—Roll Forming Machine --laminating sy... |