Trapezoidal Roof Panel Roll Forming Machine

We also design the as per your required profile drawing

SURFACE TREATMENT

1) Processing material: aluminium/zinc/galvanized steel/colored steel coil

2) Material thickness: 0.3-0.7mm

3) Effective width: 1000mm

4) Feeding width: 1200mm

5) Main motor power: 4kw

6) Pump power: 4kw

7) Roller Stations: 14 stands

8) Productivity: 0-14m/min

9) Roller material: high grade NO.45 forged steel, with hard chrome plating

10) Shaft material: high grade NO.45 carbon wrought steel

11) Cutter material: Cr12 mould steel with quenched treatment

12) Shaft diameter: 70mm

13) Main frame: 350H Steel

14) Medium plate thickness: 16mm

15) Control system: PLC computer control with inveter

16) Power supply: 380V, 3 Phase, 50Hz(or as per your request)

TECHNOLOGY

Manual decoiler→feeding device→main roll forming machine→cutting system→output table, 5.5kw electric-motor, hydraulic station with 4kw electric motor, PLC control system

SALES TERMS

1). Price: Please contact us, we will try to give you good discount for starting our cooperation

2). Payment term: 30%TT should be paid as advance deposit, 70%TT before shipment

Or 100% LC at sight

3). Package: naked with simple plastic film and loaded in one 20-feet container

4). Delivery time: 50 working days after receipt of the deposit

5). Guarantee: 12 months. If any part of machine breaks, we will supply it for free.

6). After sales service

This is maintained free of charge for 12 months. When the machine is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians traveling abroad, and pay 100USDdayperson.

在线联系供应商

Other supplier products

| 2-Wave Highway Guardrail Roll Forming Machine | We also can design the as per your required profile drawing SURFACE TREATMENT 1) Processing material: steel strip 2) Material thickness: 2.5mm... | |

| YC 914-75 Steel Floor Deck Roll Forming Machine | Floor Decking Roll Forming Machine We also can design the according to your required profile SURFACE TREATMENT 1) Processing material: galvanize... | |

| Door Panel Forming Machine | SURFACE TREATMENT 1) Processing material: aluminium/zinc/galvanized steel/colored steel coil 2) Material thickness: 0.3-0.7mm 3) Effective width:... | |

| 4M Barrel Corrugated Sheet Forming Machine | Barrel Corrugated Sheet Forming Machine SURFACE TREATMENT (1) Processing material: galvanized steel sheet, aluminium sheet (2) Material thickn... | |

| YC 1250MM Embossing Machine | SURFACE TREATMENT (1) Processing material: galvanized steel sheet, aluminium sheet (2) Material thickness: 0.25-0.55mm (3) Feeding width: wi... |

Same products

| 镁锭/镁合金锭抛光机 | 卖方: 濮阳市名利石化机械设备制造有限公司 | 镁锭抛光机/镁合金锭抛光机 它可以去除镁锭/镁合金锭的杂质、缺陷,使其表面光滑平整。 | |

| 铝锭切屑机 | 卖方: 濮阳市名利石化机械设备制造有限公司 | 我们有铝锭切屑机和铝锭制粒制粉生产线。该生产线由铝锭切屑机、造粒机(制粒机/磨机)组成。切屑机将铝锭切成屑,造粒机将屑磨成颗粒或粉末。您可以根据需要购买设备或生产线。 | |

| MTL5582B MTL Intrinsically Safe Isolator 5500 Series RTD-RTD Isolator | 卖方: 840499 | MTL 5500 Intrinsically Safe Isolators Resistance Isolator MTL5582B MTL4582B - MTL5582B RESISTANC... | |

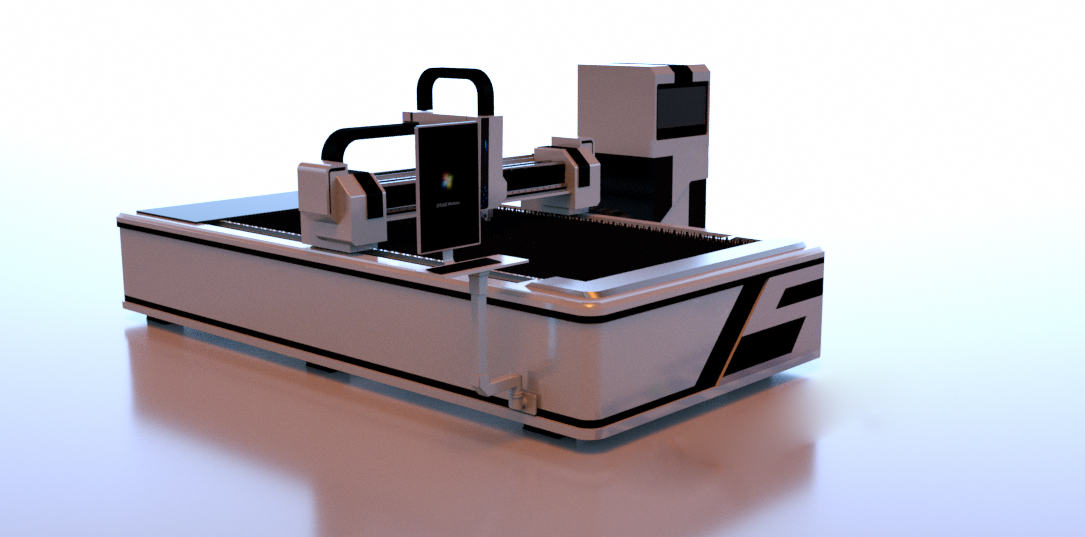

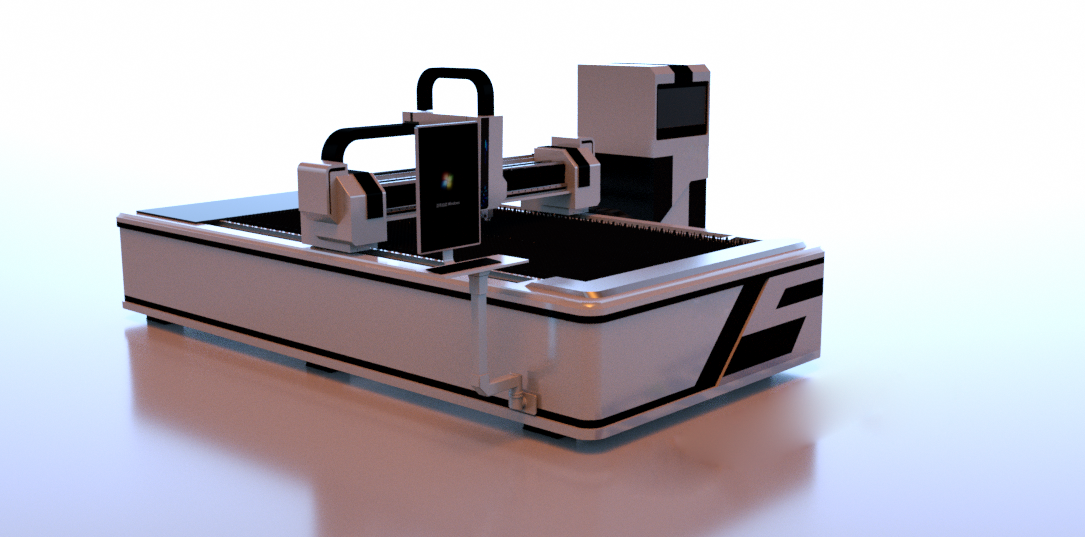

| 3015 fiber metal cnc laser cutting business | 卖方: 济南威华机械设备有限公司 | 管道必须由铜或 VA 不锈钢制成,无氧化且清洁,授权的燃气安装人员必须首先根据上述规定确定处理气体的燃气管道尺寸 | |

| 3015 fiber metal laser cutter for sale | 卖方: 济南威华机械设备有限公司 | 3015 光纤金属激光切割机出售 3000x1500mm 切割尺寸 切割气体 切割气体消耗量 O2 或 N2 管路和机器连接之间的工艺进料连接器 (O 2 2/N 2 2 ) 必须由客户... |