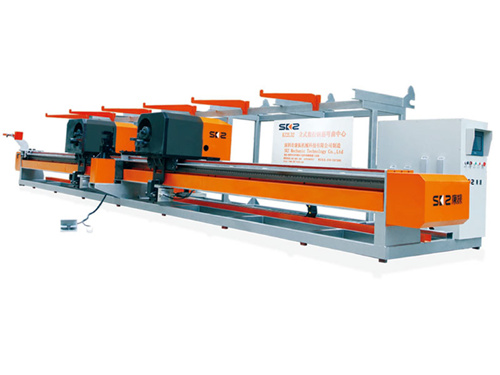

Space saving Integrated Rebar Cutting

A perfect Combination of rebar shear line &rebar bending center

Highlights:This production line is a perfect combination of rebar shearing line and rebar bending centerAn integrated equipment with the function of both shearing and bendingIt realizes lean manufacturing of rebar processingSpace saving: no space required for cut-to-size rebar, the combined machine covers an area of 120㎡Save labor: the machine is with direct consignment, save the labor for lifting and carryingImproved efficiency: process the raw material into semi-finished bends with minimum durationguaranteed quality: the working procedure is closely connected, enables to detect abnormal conditions and correct it without delayEasy operation: equipped with humanized running program and modularized setting. easy to operate

|

Model |

KQW32BX |

||||||||||||||||||

|

Max Shear Foree (KN) |

1750 |

||||||||||||||||||

|

Conveying Speed(m/min) |

≤60 |

||||||||||||||||||

|

Max Steel Strength (MPa) |

570 |

||||||||||||||||||

|

Cutting Langth (mm) |

Manual |

0-1200 |

|||||||||||||||||

|

Automatic |

1200-12,000 |

||||||||||||||||||

|

Culling Capacity |

(φ)(mm) |

10 |

12 |

14 |

16 |

18 |

20 |

22 |

25 |

28 |

32 |

36 |

40 |

||||||

|

17 |

14 |

12 |

11 |

9 |

8 |

8 |

5 |

5 |

4 |

2 |

2 |

||||||||

|

15 |

12 |

11 |

9 |

8 |

7 |

7 |

5 |

4 |

3 |

2 |

2 |

||||||||

|

Average Pewer Consumption (KW/h) |

25 |

||||||||||||||||||

|

Max Bending Angle (°) |

(φ10-φ28) +180 -100(φ32) +90 -90 |

||||||||||||||||||

|

Max Bending Size (mm) |

10500 |

||||||||||||||||||

|

Min Bending Size (mm) |

90 |

||||||||||||||||||

|

Min Bending Size Length (mm) |

(φ10),(630)(φ25),(650) |

||||||||||||||||||

|

Length Tolerance (mm) |

±2 |

||||||||||||||||||

|

Bending Tolerance (°) |

±1 |

||||||||||||||||||

|

Speed Control |

CNC Servo control |

||||||||||||||||||

|

Labeled elechic Power (kw) |

14 |

||||||||||||||||||

|

Moving Speed (m/s) |

|||||||||||||||||||

|

Bending Speed (°/s) |

65 |

||||||||||||||||||

|

Cylinder Pressure (Mpa) |

|||||||||||||||||||

|

Manufacture range |

Strand Diameter φ(mm) |

10 |

12 |

14 |

16 |

20 |

22 |

25 |

28 |

32 |

|||||||||

|

Nos to be sheared (pcs) |

6 |

5 |

4 |

3 |

3 |

2 |

2 |

1 |

1 |

||||||||||

|

Weightlkg) |

4500 |

||||||||||||||||||

在线联系供应商

Other supplier products

| VERTICAL DOUBLE BENDER | VERTICAL DOUBLE BENDER,high efficiency rebar shear-line,Vertical Double Bender Factory high efficiency rebar shear-line Vertical Double Bender Fa... | |

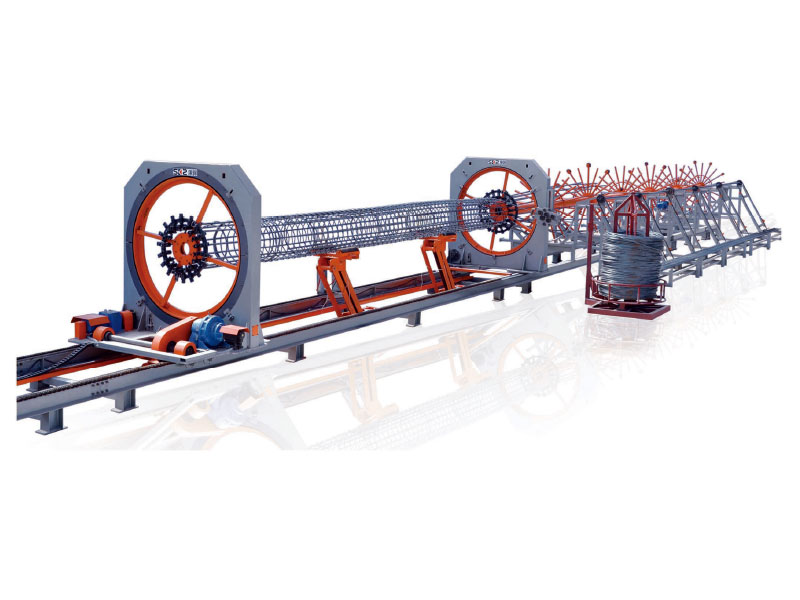

| Cage Making Machine Factory | The construction of the steel cage is the significant part of the basic bridge construction.In the past of the traditional construction, reinfor... | |

| high output Truss Girder Welding Machine | Highlights: International famous trademarks are selected for key driving parts, actuators, and electric/pneumatic components; the life cycle... | |

| automatic stirrup bender machine | KZ12ADX is special model to manufacture stirrup bender from straight bar.The machine is capable of providing our clients the most accurate ... | |

| INTEGRATED REBAR CUTTING & BENDING MACHINE | INTEGRATED REBAR CUTTING & BENDING MACHINE,Space saving Integrated Rebar Cutting,Save labor Integrated Rebar Cutting Space saving Integrated R... |