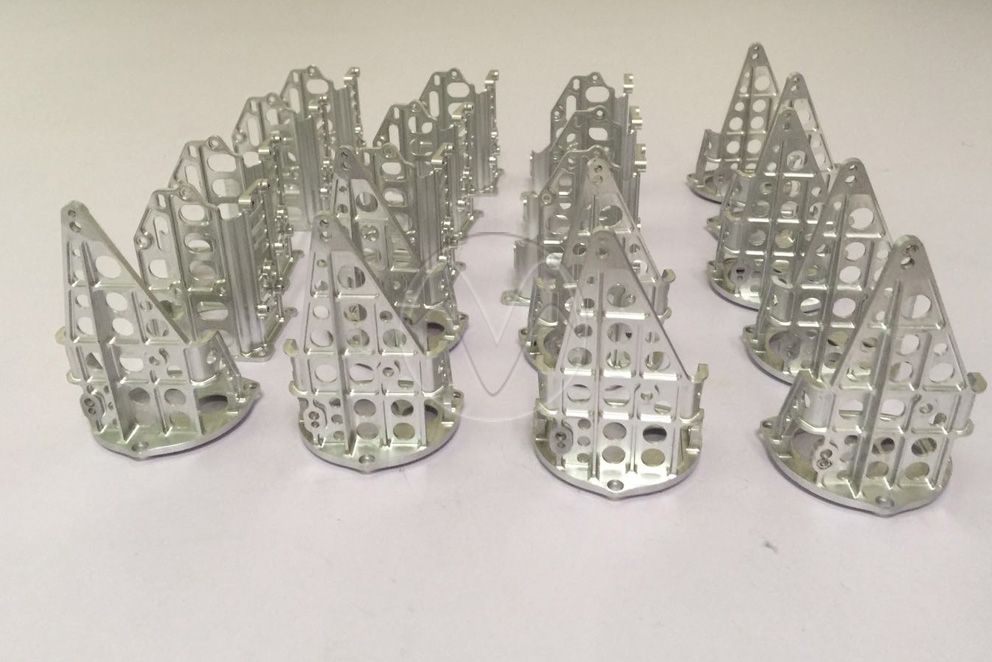

Motorcycle Parts with Metal Injection Molding

Motorcycle Parts with Metal Injection Molding

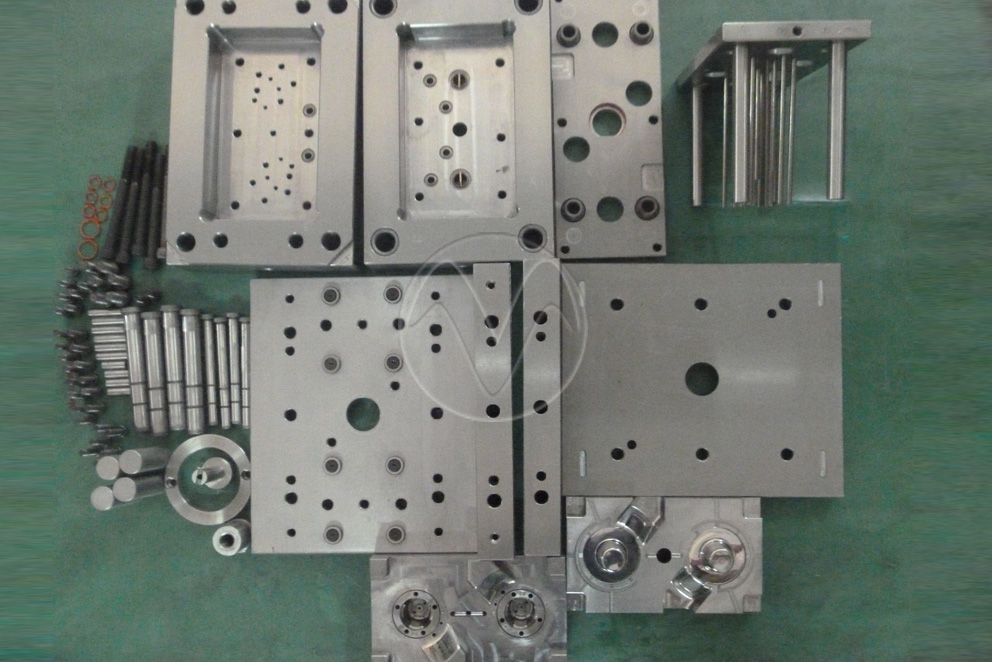

Motorcycle Parts Mold,Motorcycle Parts Stampings

In the automobile production industry, the body, chassis, fuel tank, radiator plate of the automobile, the steam drum of the boiler, the casing of the container, the iron core silicon steel of the electric motor and the electric appliance are all stamped and processed. There are also a large number of stamping parts in instruments, household appliances, bicycles, office machinery, living utensils and other products.

PRODUCTDESCRIPTION

In the automobile production industry, the body, chassis, fuel tank, radiator plate of the automobile, the steam drum of the boiler, the casing of the container, the iron core silicon steel of the electric motor and the electric appliance are all stamped and processed. There are also a large number of stamping parts in instruments, household appliances, bicycles, office machinery, living utensils and other products.

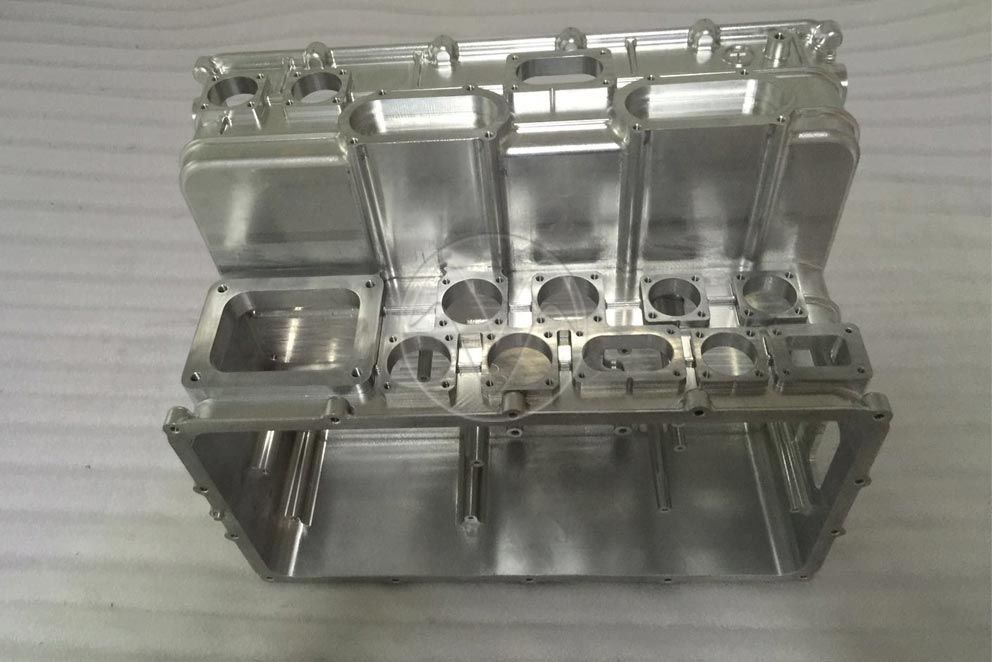

Compared with castings and forgings, precision stampings are thin, uniform, light and strong. Stamping can produce workpieces with ribs, ribs, undulations or flanging that are difficult to manufacture by other methods to increase their rigidity. Thanks to the use of precision molds, the precision of the workpiece can reach micron level, and the repeatability is high and the specifications are the same, and the holes, bosses and the like can be punched out. The surface and intrinsic properties of stamping sheets have a great influence on the quality of stamped products. Metal stamping processing has the following requirements for stamping materials:

2, the surface is smooth, no spots, no flaws, no scratches, no surface cracks, etc.;

5, low yield ratio, work hardenability.

Stamping processing is an efficient production method. It adopts composite molds, especially multi-station progressive molds, which can complete multiple stamping processes on one press to realize unwinding, leveling, punching, forming and finishing of strips. Fully automatic production. High production efficiency, good working conditions, low production costs, and generally can produce hundreds of pieces per minute.

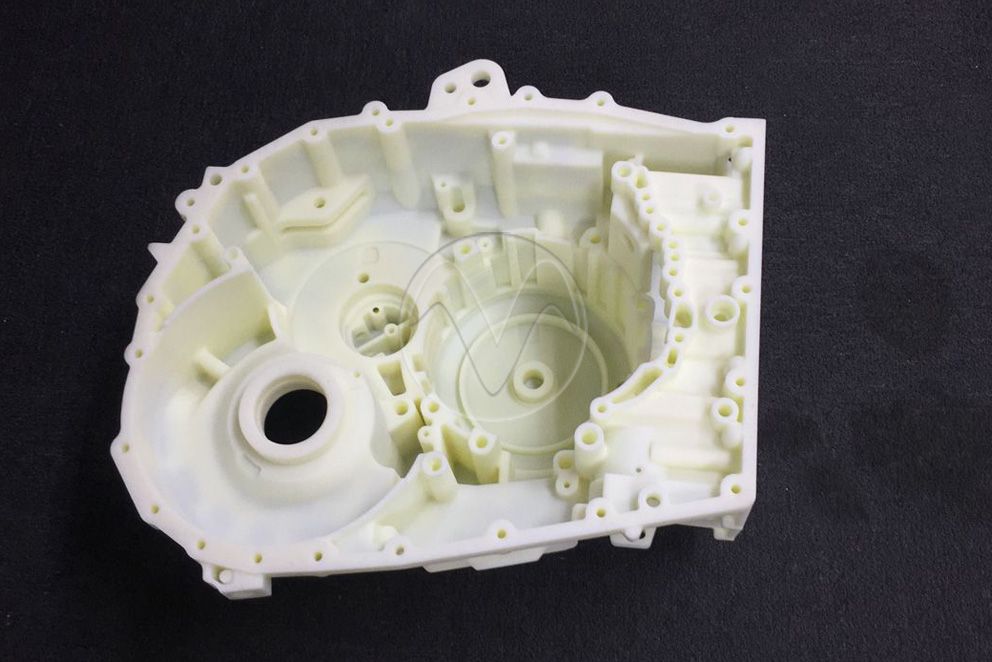

273D Printing Plastic Injection Molding 3d mold maker

在线联系供应商

Other supplier products

| Plastic injection mold products | Plastic injection mold products Injection Mold Aluminum Parts,Plastic Injection Mold Service Metal stamping dies and plastic processing dies are ... | |

| Plastic ABS Prototype Samples With CNC Machined | Plastic ABS Prototype Samples With CNC Machined ABS Rapid Prototypes,ABS Robot Prototype CNC prototype manufacturing is a method of using a CNC mac... | |

| Precision Aluminum prototype with CNC machined | Precision Aluminum prototype with CNC machined CNC Anodized Aluminum Prototype,Aluminum Metal Prototype Cutting - sawing, shearing, or chiseling (m... | |

| Aluminum Die Casting Mould | Aluminum Die Casting Mould Injection Mold Aluminum Parts,Plastic Injection Mold PRODUCTDESCRIPTION The difference between machined aluminum and ... | |

| Plastic ABS prototype with vacuum casting | Plastic ABS prototype with vacuum casting Plastic ABS Prototype,vacuum casting Average shrinkage value: +/- 0.3mm Maximum size:2500*800*800mm Toler... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |