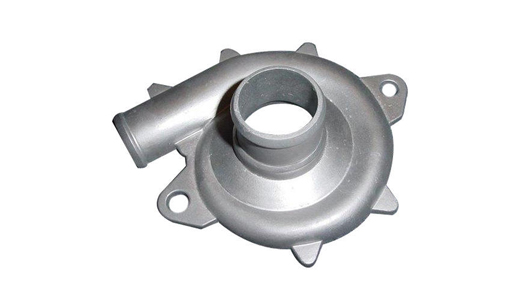

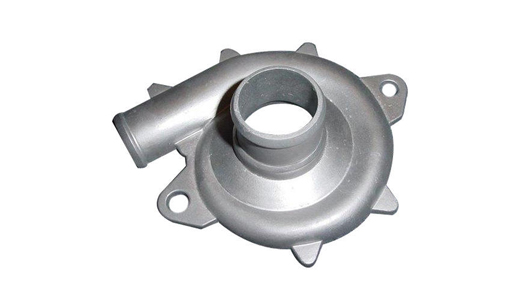

Vacuum Investment Casting

Vacuum investment castingis one of the precision investment casting methods. This special technic is mainly applying to producing the small but high requirements casting items such as aircraft parts, jewelry, and accessories. The term, vacuum investment casting, refers to the process of melted metal pouring into the mold under negative pressure. This negative pressure is created by a vacuum machine. In this way, the product is able to be the exquisite masterpiece that the designer wishes to present. And this method can meet the mass production requirement, the change of style and variety can be considered at the same time.

The Process of Vacuum Investment Casting

The vacuum investment casting jobs is carried on in the specific furnace which is can be categorized by 2 types according to their product metallurgical characteristics: the equiaxed, and the controlled solidification castings. For the first type, there's no special consideration to control the solidification in the mold. But for the furnace with controlled solidification, it has the ability to exert a high level control on the solidification process in the mold.

The application of Vacuum Investment Casting

The aerospace industry is one of the major applications during the melting of metal material for vacuum investment casting. Because there're many complex alloys and superalloys, such as titanium and nickel-based parts are used in this industry. Melting these alloys in a vacuum, under an oxygen-free atmosphere, limits the formation of nonmetallic oxide and nitride inclusions in the metal.

Advantages of Vacuum Investment Casting

Investment casting process advantages and disadvantages of precision casting, also known as investment casting, with other casting methods and parts forming methods compared to investment casting has the following advantages.

In summary, precision casting has the advantages of small investment scale, large production capacity, low production costs, complex product process simplification, fast investment. Thus, in competition with other processes and production methods in a favorable position.

Rayforce Manufacture is a privatemetal casting company, we provide metal casting china, vacuum die casting and etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Low Pressure Die Casting | The low pressure die casting is to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting par... | |

| Squeeze Die Casting | The squeeze die casting, also called extrusion casting or liquid die forging, is a kind of newly developed metal forming technic that combines the ... | |

| Low Pressure Die Casting | The low pressure casting machineis to let the melted metal flow into the casting mold under a certain degree of pressure, and solidify the casting ... | |

| Green Sand Casting | Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, ... | |

| Vacuum Die Casting | The vacuum pressure casting, as this name indicates, is casting method which the major processes including the melting, pouring, solidifying are pe... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |