ENGINE BRACKET/ENGINE MOUNTING BRACKET

Car engine mounting bracketwhich is divided into two parts is a component of automobile engine. The first one is torsional bracket, the second one is engine mounting rubber whose main function is fix the shock absorption. Torsion bracket is a kind of engine fastener, which always connected to the engine on the front axle of the vehicle body. It is different from the ordinary engine mounting rubber is that the mounting foot is a rubber pier directly installed in the bottom of the engine, and the torsional bracket is similar to the appearance of an iron bar installed in the side of the engine. There is also a torsional bracket rubber on the bracket, which plays the role of damping.

- car engine bracket

The car engine bracket is the part that holds the engine in the car. In most cars, the engine and transmission are bolted together and secured together by three or four bases. Part of the car engine bracket is bolted to the body or frame. The other part holds the engine. The engine is a source of vibration because it has many moving and rotating parts. Car engine bracket's job is not only to hold the engine in place, but also to reduce the engine vibration felt in the car. To further suppress vibration, some car engine bracket are filled with liquid and act as shock absorbers. The car engine bracket does not require any maintenance or regular maintenance and needs to be replaced only in the event of failure or wear and tear.

The working principle of engine bracket is to fix the engine firmly on the subframe or engine base of the car. It is one of several mounts that hold the engine and transmission together and in place. In this way, the metal surface of the engine does not friction with the metal surface of the body, allowing the shock wave to pass through the car, and rubber is used to fill the engine bracket. Some automakers use vacuum control or electromagnetic mounting to further control vibration absorption. Problems occur when the installation material begins to deteriorate.

Hybrid electric vehicle

|

Material |

A380、ADC12 |

|

Casting Process |

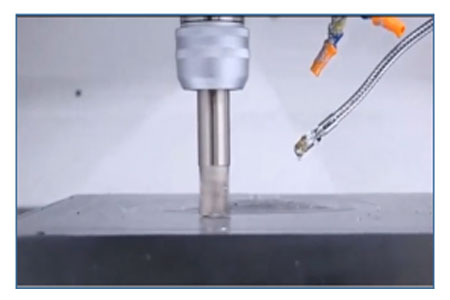

HPDC |

|

Die Casting Machine |

250-1000T |

|

Weight |

Depending on part size |

|

dimension |

Depending on part size |

|

Annual Volume |

60,000 per year |

|

Porosity requirements |

ASTM E505 Level 3 |

|

Leakage test requirement |

/ |

|

Application |

OEM |

EMP Techis a die-casting parts manufacturerand engine bracket car, mounting an engine, mounting bracket material, casting bracket design, bracket automotive, bracket engineand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Services | Bioanalytical Service Bioanalytical Service for Small Molecule Drugs and Metabolites, Large Molecules – Peptides and Proteins, etc. LCMSMS Q... | |

| TELECOM PARTS | Telecommunication PartsOverview Vehicle telecommunication is often developed as part of the Intelligent Transportation System (ITS). A vehicle tele... | |

| ENGINE OIL PAN | Engine Oil Pan The oil panis an important part of automobile engine and an indispensable part of engine lubrication system.By sealing the lowe... | |

| CNC MACHINING | EMP Techis a global, full-service aluminum die casting manufacturer china. With more than 20 years' experience in research & development, manuf... | |

| DIE CAST TOOLING | The tooling room is also the process equipment room, and various tools used in the manufacturing process, such as tools, fixtures, molds, measuring... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |