Die Casting

Die Casting

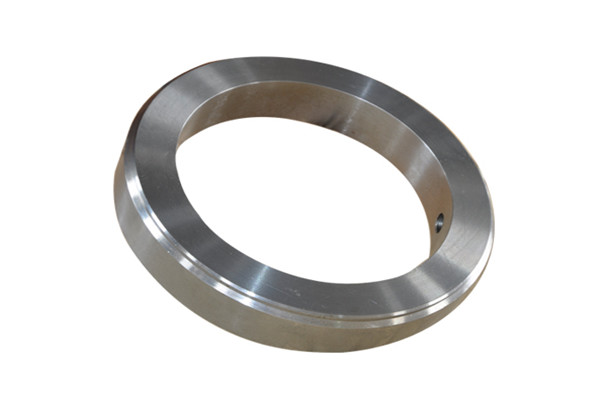

As a professional aluminum die casting co inc, ETCN provides our clients qualified mould die castingservice. The product uses a die-casting process to complete the blank, CNC servicemachining and polishing treatment, suitable for auto parts. In addition, diecasting servicesincludes different types of materials such as zinc pressure die casting, aluminum pressure die casting, brass die casting, copper die casting, cast iron die castingand etc.

Advantage of Die Casting

High Material Utilization Rate

Due to the high precision of casting process, die-casting parts can be assembled and used only after a small amount of mechanical processing, and some die-casting parts can be directly assembled and used. The material utilization rate is about 60%-80%, and the blank utilization rate reaches 90%.

Good Product Quality

The dimensional accuracy of injection die castingengineering is high, generally equivalent to 6~7, or even up to 4; the surface finish is good, generally equivalent to 5~8; the strength and hardness are higher, and the strength is generally 25~30% higher than sand casting, but it is extended.The rate is reduced by about 70%; the size is stable, and the interchangeability is good; it can be used in thin-walled complex castings. For example, the current minimum wall thickness of zinc alloy die castings can reach 0.3 mm; aluminum alloy castings can reach 0.5 mm; the minimum casting aperture is 0.7 mm, and the minimum pitch is 0.75 mm.

High Production Efficiency

Machine productivity is high. For example, the domestic JⅢ3 horizontal cold-air die casting machine can die-cast 600-700 times in eight hours on average, and the small hot-chamber die-casting machine can die-cast 3,000-7000 times in eight hours on average. The die-casting mold has a long life and one pair of die-casting molds. The die-cast clock alloy has a life span of hundreds of thousands or even millions of times; it is easy to realize mechanization and automation.

Excellent Economic Effect

Due to the precise size of the die casting and sand castingthe surface is smooth and clean. Generally, it is not used for mechanical processing but directly used, or the processing volume is small, so it not only improves the utilization rate of metal but also reduces a large number of processing equipment and man-hours; and reduces die casting cost; combination die-casting can be used with other metal or non-metal materials. Our mental casting services like iron casting services save not only assembly man-hours but also metal.

Easy To Use Inserts

It is easy to set a positioning mechanism on the hot chamber die casting and cold chamber die castingmold to facilitate insert casting of inserts and meet the local special performance requirements of die-casting parts.

在线联系供应商

Other supplier products

| Forging | Forging production is one of the main processing methods to provide mechanical parts blank in the mechanical manufacturing industry. Through forgin... | |

| CNC Grinding | After CNC milling or CNC turning forming, the surface roughness and behavior tolerance requirements of products are completed by CNC grinding, and ... | |

| Forging | Precision forgingproduction is one of the main processing methods to provide mechanical parts blank in the mechanical manufacturing industry. Throu... | |

| Industrial Machining and Manufacturing Services Application | As a custom plastic molding company, ETCN has experience in cooperating with companies in various fields, relying on a complete industrial chain to... | |

| CHINA CUSTOM CNC MACHINING SERVICE | As a China CNCmachining medicalsupplier with over 20 years of experience, ETCN is specialized in offering custom CNCplastic machining services. As ... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |