OEM PARTS WITH DIE CASTING

Definition of aluminum die casting parts

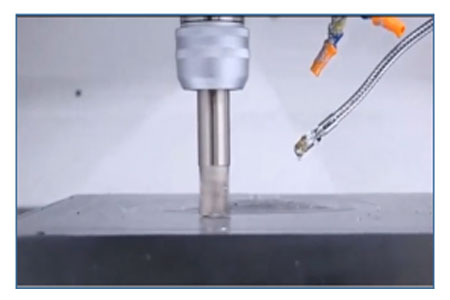

Aluminum alloy die casting is a kind of pressure casting part, which uses the die casting mechanical die casting machine to install the casting mould, and pours the heated liquid aluminum alloy into the feed port of the die casting machine. The aluminum alloy parts with limited shape and size of the die are cast by the die casting machine. Such parts are usually called aluminum alloy die castings.

Advantages of oem casting parts

Because the metal aluminum alloy has good fluidity and plasticity.Aluminum alloy die castings can not only make a variety of complex shapes, but also have high precision and finish.The mechanical processing of castings and the casting allowance of metal aluminum alloy are reduced, which not only saves electric power and metal materials, but also greatly saves labor costs.Aluminum alloy has excellent thermal conductivity, low specific gravity and high processability.

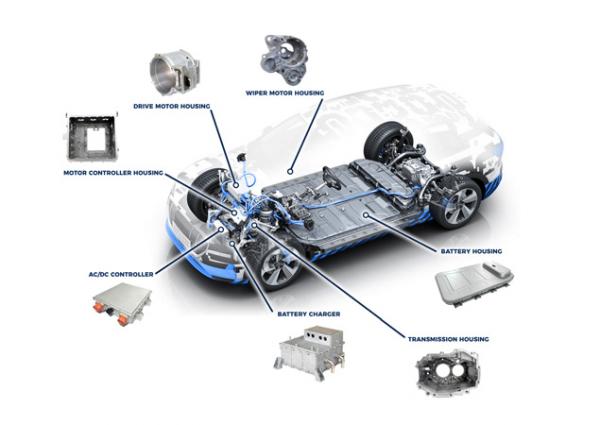

Applications of automotive parts die casting

Aluminum alloy die castings are widely used in automobile manufacturing, internal combustion engine production, motorcycle manufacturing, motor manufacturing, oil pump manufacturing, transmission machinery manufacturing, precision instruments, landscaping, power construction, architectural decoration and other industries.

Aluminum alloy automotive casting componentscan be made into aluminum die-casting automobile parts, aluminum die-casting automobile engine fittings, aluminum die-casting engine cylinder, aluminum die-casting gasoline engine cylinder head, aluminum die-casting valve support, aluminum die-casting power accessories and other parts.

Recycling automotive aluminum die casting

There is little difference in the function of primary and secondary recycled aluminum die-casting. Secondary aluminum alloy is made of pure aluminum mixed with magnesium, iron, copper and other materials. Due to cost, it is rarely used in pure aluminum casting. More than 95% of aluminum castings made in North America are made from recycled aluminum after consumption. The ease of use of aluminum alloy in die casting and its lighter weight and durability make it the first choice for designers in almost all industries, for which secondary aluminum needs only 5% of energy to be produced. Most of the energy consumption of aluminum die casting is used to heat and remelt the metal in the manufacturing process.

EMP Tech, as an excellent die-casting parts manufacturer, offers a wide range of aluminium parts for you to choose from.

在线联系供应商

Other supplier products

| GAS CAR PARTS | Aluminum die castings can be used in wiper systems, engine systems, filter systems, air conditioning systems, precision compressor parts, shock abs... | |

| ALUMINUM DIE CASTING VALVE PARTS | Aluminum Die Valve CastingParts Product Details: As one of die cast aluminum suppliers, we have types of related products for sale... | |

| CUSTOM BRACKET ADC12 ALUMINUM DIE | Commonly used custom mounting bracketsare custom aluminium mounting brackets, automobile generator brackets, engine brackets, and seat brackets. ... | |

| ALUMINUM MOUTING BRACKET | The aluminium mounting bracketsare made of aluminum alloy, which can not only be integrated, but also stable and safe. As a professional casting... | |

| DIE CAST TOOLING | The tooling room is also the process equipment room, and various tools used in the manufacturing process, such as tools, fixtures, molds, measuring... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | 卖方: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | 卖方: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| 陶瓷型芯注射机 | 卖方: 秦皇岛埃孚科技有限公司 | 陶瓷型芯注射机主要用于形状复杂,高品质、高精度铸件的陶瓷型芯的成型。该设备通过吸收国内外先进制造技术和精铸行业的自身特点,研制开发成功。 合模力:35T-100T | |

| 压蜡机 | 卖方: 秦皇岛埃孚科技有限公司 | 注蜡机用于精密铸造生产中蜡模的制作。合模力最大 :10T-150T | |

| 全自动脱蜡釜 | 卖方: 秦皇岛埃孚科技有限公司 | 脱蜡釜,是精铸生产中的型壳脱蜡专用设备 内腔尺寸: Φ1000×1200mm/ Φ1200×1500mm/ Φ1400×1600mm |