Ways to Make Coal Briquette Plant More Efficient

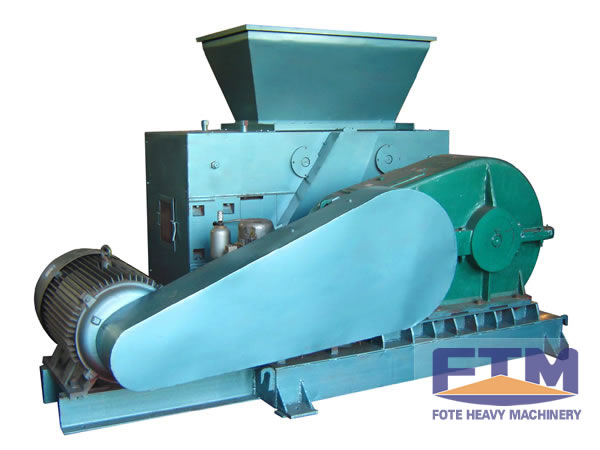

Coal briquette plant, also named as coal briquetting plant, is mainly used to process the coal wastes into briquettes of great value.To improve the working efficiency of coal briquette plant, you should take the factor of heat dissipation into accounts. According to the density of coal briquettes, you can flexibly adjust the pressure of coal briquette press.

.jpg)

Through the open gears, driving shaft and driven shaft can move simultaneously. After well installing the coal briquetting machine, you should make a trail run.If distance between rollers is too large, powered coal will fall off while molding pressure has no chance to be delivered to the central part. What’s worse, coal briquettes will be much poor in performance.

Hydraulic device, being installed in coal briquette plant, is located behind the seat of passive bearing.Spiral feeder, driven by the Electro-magnetic Speed-adjustable motors, can compulsively suppress raw materials into the major feeding mouth through the belt pulley and worm reducer.

When the feeding amount of spiral feeder equals to the required amount of dynamo, electro-magnetic speed-adjustable motors can keep constant feeding pressure to make briquettes stable in quality.If feeding amount is too large, electric overload on feeder will occur. If feeding amount is too small,working failure of coal briquetting machinewill occur.

Known as theNO.1 brand of coal briquette press, Fote briquetting machine manufacturer never stops its way to offering the best products and services for you! Looking forward to working with you in the near future.

Fote Heavy Machinery:

Fote Official Email:

在线联系供应商

Other supplier products

供应产品

Effort of FTM Crusher Company to Predict Risks

In the first three months of 2015, the national economy of China develops quite well. While, we need to realize that there still exist some unstabl...

Importance of Wood Pellet Mill for Structure

Featured in the high thermal efficiency, wide application ranges and easy storage, biomass particles can be used as the ideal substitutes of natura...

Powerful Application of Straw Pellet Mill in China

For countries rich in the biomass energy, they can powerfully apply the straw pellet mill in rural areas. The application of straw pellet machine c...

Efforts of Fote to Make Hydraulic Briquette Press

Hydraulic ball press machine, also named as hydraulic briquette press machine, is an amazing machine with the ability to turn wastes into things of...

Technical Advantages of FTM Hammer Crusher

Different crushers have different technical advantages. Compared with other crushers, hammer crusher machine is more obvious in the following techn...

Same products

YZH WHEN1500固定式液压机械臂

卖方: 山东伊润基础工程有限公司

以下是YZH WHEN1500固定式液压拆除臂的详细介绍,包括其特点、优点和案例研究:YZH WHEN1510固定式底座碎石机臂的特点:智能多模式控制:支持驾驶室操作、无线/有线远程控制、光纤+...

YZH WHEN1410固定式底座碎石机

卖方: 山东伊润基础工程有限公司

YZH WHEN1410固定式底座碎石机是一种专为采矿、冶金及相关行业大型物料的二次破碎而设计的专用设备。通过更换附件(如液压锤或莲花爪),它可以执行多种功能,包括破碎、抓取和拆除。 WHEN...

YZH WHEN 1300固定式底座碎石机

卖方: 山东伊润基础工程有限公司

WHEN 1300固定式底座碎石机的特点:智能多模式控制:支持驾驶室操作、远程控制和视频监控。远程控制范围可达10-20km,集成有线/无线双模操作。配合高性能控制器,可实现精确定位和灵活控制。...

WHE1500 Pedestal Breaker Boom Systems

卖方: 山东伊润基础工程有限公司

WHE1500底座式断路器臂架系统的特点: WHE1500底座破碎机臂系统是一种集机械、电气和液压系统于一体的专用二次破碎装置。其设计解决了采矿、冶金和相关行业中的材料堵塞和大块破碎挑战。 采用...

元征行固定式液压破碎机械:矿山破碎领域的智能环保高效解决方案

卖方: 广西元征行机械设备有限公司

在矿山、冶金、铸造等行业的二次破碎环节,一款性能卓越的破碎设备至关重要。元征行机械设备有限公司推出的固定式液压破碎机械,凭借科技智能、节能环保、高效可靠的突出优势,成为行业内的明星产品。

产品...