Ball Mill 15.550 Lgx4.2 M Dia/Ball Mill Aluminum Grinding

Ball mill is also known as ball grinding mill. Ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous non-ferrous metals. The ball mill can grind various ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overflow type due to different ways of discharging material. There are many types of grinding media suitable for use in a ball mill, each material having its own specific properties and advantages. Key properties of grinding media are size, density, hardness, and composition.

In terms of ongoing operations, the grinding media in Ball Mill Aluminum Grinding/Ball Mill 15.550 Lgx4.2 M Dia has a much higher wear rate compared to that of the table and rollers in a ball mill. With a ball mill, it is important to monitor the performance through axial testing, to ensure that the media grading is correct and that there is a sufficient quantity of top-size media in the mill to sufficiently grind the mill feed materials. If this is not the case, ‘nibs’ (large, unground material) will collect at the end of the first chamber and block the slots of the mill diaphragm. However, topping up the mill with additional media is a simple task and most cement manufacturers will re-grade their cement mill media on an annual basis.

The other major repairs that take place on ball mills are to replace the liners and diaphragms and on a ball mill to replace (or turn) the rollers and replace the table. The liners on a ball mill generally last up to 5 years in the first chamber and as long as 8 years in the second chamber and therefore are infrequently changed. Diaphragm plates will require changing more frequently, but certainly not on an annual basis. Whilst the wear parts on a ball mill will not require changing on an annual basis, work will be required. This could be hard-facing the roller and table or reversing the roller segments. Eventually the wear parts will require replacement. Therefore the maintenance requirements of the ball mill are higher than those of the ball mill. Overall, the maintenance costs are not dissimilar for both types of mills: while the wear rates for a ball mill are higher than for a ball mill, the cost of the replacement parts is lower, and the opposite applies for the ball mill – i.e. lower wear rate but higher replacement costs.

On the basis of service for customers, Henan Fote Heavy Machinery Co., Ltd. continuously innovate and boldly

conceived to ensure a leading position in key technology area. Product quality and the good service is considered the life of our company, so we have many excellent engineers and efficient salesman which can guarantee the customer getting the satisfaction product and the latest product news they want. Quality and service are not only the principle of permanent insisting on but also the main cause that the customers are willing to establish stable business relationship and long-term cooperation with us.

Contact Infomation

Email:

Website:

Address: High and New Industrial Zone, Kexue Revenue, High and New Technology Industrial Development Zone, Zhengzhou, China

在线联系供应商

Other supplier products

| Gold Ball Mill Prices/Mini Gold Ore Ball Mill Machine | Descriptions of Gold Ball Mill Prices/Mini Gold Ore Ball Mill Machine Gold Ball Mill Prices/Mini Gold Ore Ball Mill Machine is the key re-crush eqi... | |

| Smooth Roll Crusher Type 2411/Double Roll Crusher For Hard Stone | With the development of our country each industry grows, roll crusher has a large number of sales, the crushing roll crusher for ore dressing, che... | |

| Diesel Powered Lime Kilns/Large Capacity Active Lime Rotary Kiln | Large Capacity Active Lime Rotary Kiln/Diesel Powered Lime Kilns is used for calcimine of high aluminum vandal ochre in refractory material indust... | |

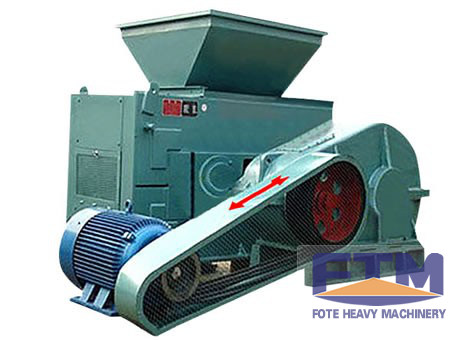

| Hot Selling Aluminum Scrap Briquette Machine/Aluminium Powder Briquette Machine With High Quality | Aluminum powder briquette machine with best price are the equipments pressing powdered materials into ball shape. The design of the product is mai... | |

| Copper Ore Processing Plant/Magnetite Iron Ore Beneficiation Plant | Iron ore is an important raw material for the steel manufacturing companies and all rocks that contain iron element or iron compound can be called... |

Same products

| YZH WHEN1500固定式液压机械臂 | 卖方: 山东伊润基础工程有限公司 | 以下是YZH WHEN1500固定式液压拆除臂的详细介绍,包括其特点、优点和案例研究:YZH WHEN1510固定式底座碎石机臂的特点:智能多模式控制:支持驾驶室操作、无线/有线远程控制、光纤+... | |

| YZH WHEN1410固定式底座碎石机 | 卖方: 山东伊润基础工程有限公司 | YZH WHEN1410固定式底座碎石机是一种专为采矿、冶金及相关行业大型物料的二次破碎而设计的专用设备。通过更换附件(如液压锤或莲花爪),它可以执行多种功能,包括破碎、抓取和拆除。 WHEN... | |

| YZH WHEN 1300固定式底座碎石机 | 卖方: 山东伊润基础工程有限公司 | WHEN 1300固定式底座碎石机的特点:智能多模式控制:支持驾驶室操作、远程控制和视频监控。远程控制范围可达10-20km,集成有线/无线双模操作。配合高性能控制器,可实现精确定位和灵活控制。... | |

| WHE1500 Pedestal Breaker Boom Systems | 卖方: 山东伊润基础工程有限公司 | WHE1500底座式断路器臂架系统的特点: WHE1500底座破碎机臂系统是一种集机械、电气和液压系统于一体的专用二次破碎装置。其设计解决了采矿、冶金和相关行业中的材料堵塞和大块破碎挑战。 采用... | |

| 元征行固定式液压破碎机械:矿山破碎领域的智能环保高效解决方案 | 卖方: 广西元征行机械设备有限公司 | 在矿山、冶金、铸造等行业的二次破碎环节,一款性能卓越的破碎设备至关重要。元征行机械设备有限公司推出的固定式液压破碎机械,凭借科技智能、节能环保、高效可靠的突出优势,成为行业内的明星产品。 产品... |