Automatic weighing edible oil filling machine Automatic Liquid Filling Machine

Automatic weighing edible oil filling machine Automatic Liquid Filling Machine

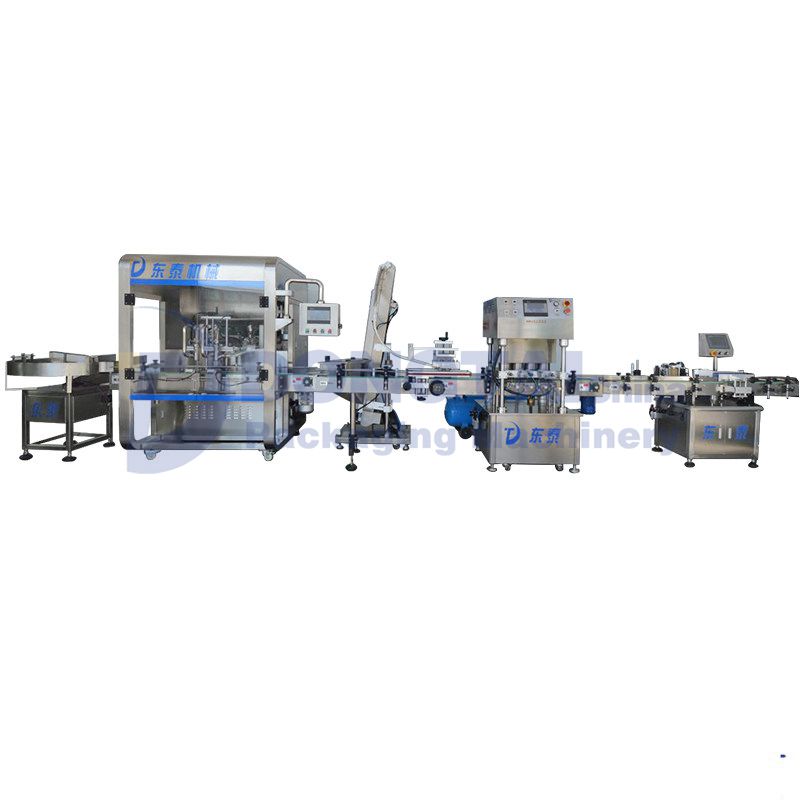

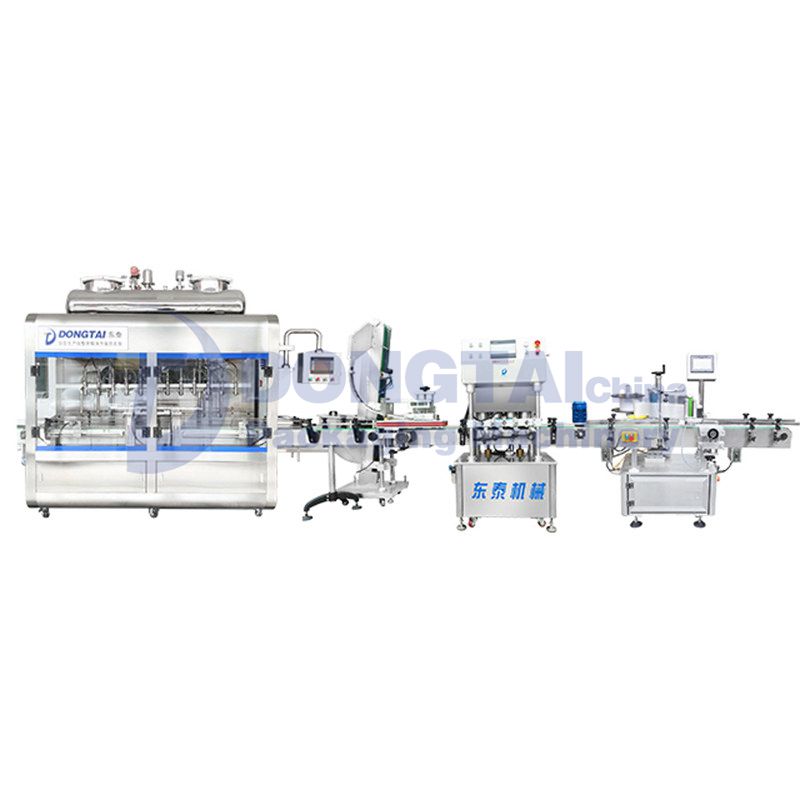

Automatic weighing edible oil filling machineis suitable for filling edible oils. The filling range is from 0.5 liters to 20 liters. The equipment is linear filling. Including filling machine, sealing machine, labeling machine to form edible oil filling line. Equipment appearance 304 stainless steel. High precision and high efficiency. It is an ideal equipment for oil filling.

Characteristic:

Automatic weighing edible oil filling machine is suitable for liquid weighting and filling from 0.5 liters to 20 liters. It is an ideal packaging machine for food, medicine, cosmetics and fine chemical industry,especially used for quantitative filling for water, edible oil and lubricating oil. This machine adopts programmable controller (PLC), high-speed industrial control configuration software for real-time monitoring control, easy to use and adjust.It also can automatically complete a series of operations such as counting into the bottle, filling by weight, conveying out of the bottle. The whole machine is made according to GMP standard. Connection of each pipe is made by quick assembly, which is convenient for disassembly and cleaning. The parts which contact with materials and exposed parts are made of high-quality stainless steel. Complete machine safety, beauty and environmental protection.

Single Head Liquid Filling Machine-Product parameters:

|

Filling head |

6 |

|

Filling volume |

5-30kg |

|

Capacity |

500-1600 barrels /H (5KG);400-560 barrels /H (30KG) |

|

Filling auuracy |

±0.1% |

|

Voltage |

220V, 50Hz |

|

Power |

3KW |

|

Air source |

|

|

Size |

2200mm*1350mm*1820mm |

|

Bottle type |

Customized |

|

Diameter of bung hole |

Customized |

Main Technical Parameters:

Advantages of the Liquid Filling Machine:

Use tempered glass forwards and backwards; simple appearance, more sense of technology2. Equipment Structure Upgraded

(1) Single head, single pump, single structure, centrifugal pump feeding structure with high precision, fast speed (fast feeding),and multi-stage speed filling. Increase 20% filling speed on the premise of ensuring the filling accuracy, increase the filling speed by 20%.The buffer tank is installed in the equipment to avoid the large filling error caused by uneven pipeline pressure.

(2) The chain conveyor is suitable for various bottle filling.

The transmission chain adopts teflon roller, less friction and more stability, which can extends the service life of the equipment.

Add clamping device for bottle mouth: more convenient for small container filling, and the positioning of filling head and bottle mouth is more accurate;

Adopts O-type baffle to shield the disadvantages of tension wheel (fish-eye is used to adjust the tightness of sprocket wheel).

The conveyance adopts teflon roller type, the container conveyance is more stable, can turn forward and backward conveyance;

(3) Using listing motor to adjust the height of the filling head . Adjust the height of the touch screen with one button. The lifting structure and the motor are connected directly through the coupling with 90 degrees, which reduces friction, reduces power and saves electricity.

(4) Filling head adopts Angle seat valve type, filling inner plug is made of teflon sealing ring to prevent corrosion of special materials ;

Submersible filling method, anti-foaming, suitable for the filling of foaming liquid.

(5) Adopt a variety of weighing modules and weighing sensor measurement method, the error is small as 0.3%

(1)The filling head is opened before the power source, so that the impact force is small and the splash can be avoided;

(2)Automatic detect barrel weight , if the tare weight of the barrel is higher or lower than the parameters built in, it will be regarded as no barrel.

No filling without barrels and automatic identification stop and start . If the number of barrels is not enough or there are no barrels in the middle, the machine will automatically identify, not filling on the position without barrels.

(3) The system has a memory function, the filling part can be turned on again after pause to continue the previous work,continuous counting;

(4) There is no barrels feeding time except the first group. The capacity is 1350 barrels per hour, filling time of each group is 16 seconds.(Filling machine with 6 filling heads,frequency changer at 25 Hz)

(5) The filling weight can be constantly monitored on the touch screen;

The whole filling process can be tracked and recorded.

The filling weight of the former group can be viewed.

DONGTAIcan provide a wide variety of filling machine such as liquid filling machine, sauce filling machine, powder filling machine and granule filling machine. Our products have high quality and competitive prices. If you are interested in our products, please click here.

在线联系供应商

Other supplier products

| Thick Sauce/Paste Filling and Capping machine Sauce Filling Machine Paste Filling Machine | Thick Sauce/Paste Filling and Capping machine Sauce Filling MachinePaste Filling Machine The granule spicy sauce filling production line adopts PLC... | |

| CE Certificate Full Auto Injection Glass Vial 20ml Bottle Filling Machine,e-Liquid Filling Capping Machine Price | CE Certificate Full Auto Injection Glass Vial 20ml Bottle Filling Machine,e-Liquid Filling Capping Machine Price Characteristic: Injection Glass Vi... | |

| Semi Automatic Filling And Sealing Machine | Semi Automatic Filling And Sealing Machine DTG-40 semi auto aluminum tube filling and sealing machineis specially design to fill all kinds of liqui... | |

| Automatic Powder Filling Machine | Automatic Powder Filling Machine All stainless steel design conforms to the santitary standards.The packaging machine is mainly used in pesticides,... | |

| Sauce Filling Machines And Production Line For Chili Sauce /Tomato Sauce/Bbq Sauce Bottled Filling Machine | Sauce Filling Machines And Production Line For Chili Sauce /Tomato Sauce/Bbq Sauce Bottled Filling Machine The automatic chili sauce sauce filling ... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |