Paper Cushion Machine

Paper Cushion Machine

LockedPaper Kraft paper cushion machine can wrinkle Kraft paper into a three-dimensional buffer, the paper cushioning machinecan effectively buffer and protect your products.

How Finished Paper Fills Will Protect Your Products

Void fill machine: To protect products from damage by filling the excess space in the box. This prevents the items inside from moving or breaking during shipment.

Paper cushioning machine: Protect items during shipment by providing stronger paper structure. Paper cushioning machine will be safely fixed in the box to reduce the chance of damage.

Wrapping: Provides protection against surface abrasion and minor handling incidents. It also prevents damages caused by internal impact when multiple items are packed together.

LockedPaper Kraft Paper Cushion Machine Benefits:

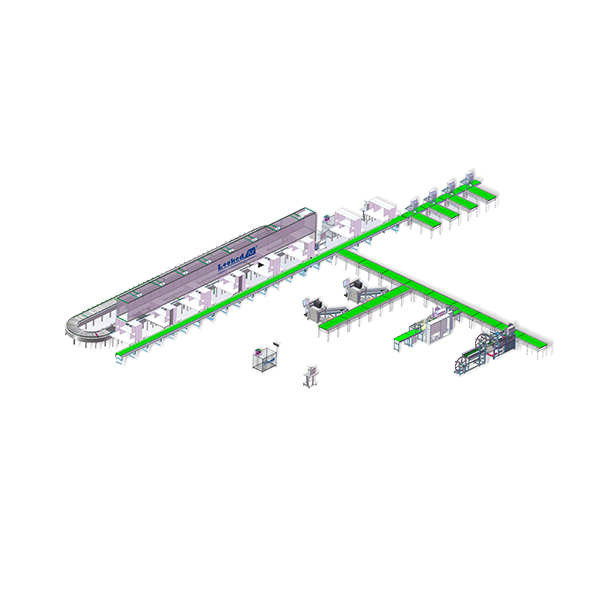

Multi-functional Operation Modes: LockedPaper's paper cushion machinecan cooperate with various types of production and packaging needs. You can set the length of paper pad meanwhile can outfeed pre-set number of paper pads so one machine can support several work stations. This helps customers to low operating cost in automatic mode.

Green Production Process: effective buffer material , 100% biodegradable, 100% recyclable, 100% reusable.

Unique Patented Technology: Our paper void fill packaging machinecan convert the multi-layer kraft paper into a three-dimensional structure to provide effective protection.

Smart Design: Light exterior design and easy to operate. The entire paper void fill system can automatically detect paper jams in the machine or out-of-paper in the material bin.

Higher Safety: all-hazard area are high isolated for double insurance operation.

Higher Efficiency: The paper speed of the system can reach 72 meters per minute.

Difference Between Air Cushion MachineAnd Paper Cushion Machine:

Comparing with air cushion machine, paper void fill machine can be used for heavy or spiny products to eliminate the damage of a product in the box during transport.

Paper Void Fill Machine Service Support & Maintenance

Our wide and well-established network of dealers ensures that our customer support is fast and responsive. We offer world class, fast service support to you with technical expertise, parts supply, repair, and replacement. There’s always a prompt response you need help.

Paper Void Fill Machine Packing Techniques

Blocking

The product and the outer packaging are separated by two cushioning material crosses to ensure that the impact from the outer packaging is reduced by the cushioning material before it reaches the product in the process of transportation.

Cushioning

The cushioning material is bent and rolled into a ball and filled between the product and the outer packaging.

Bracing

Cushioning material is used between the product and the outer packaging to prevent the product from shaking inside the carton.

For more information about Air Cushion Packing System, please feel free to contact us!

在线联系供应商

Other supplier products

| Box Auto Bagger | Introduction Of auto box packing machine With the faster growing sales and broader product selection brought to the business, most e-commerce comp... | |

| LockedPaper-F1 Kraft Paper Void Fill Machine | Introduction Of LockedPaper-F1 Kraft Paper Void Fill Machine Paper Cushioning System for void filling and light load blocking LockedPaper F1 kr... | |

| Movable Basket | Introduction Of Movable Basket Movable cart with bin, optional sensor function to have automatic start / stop function. Specifications Of movable ... | |

| Protective Automated Mailer System | Introduction Of Protective Automated MailerSystem Intelligent packaging machine designed for protective packaging of random product with bubble wr... | |

| Air Bubble Bag | Introduction of air bubble bag: Air Bubble Bag-MF series. Design for wrap protection. Absorbing the shock with positive pressure air inside.... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |