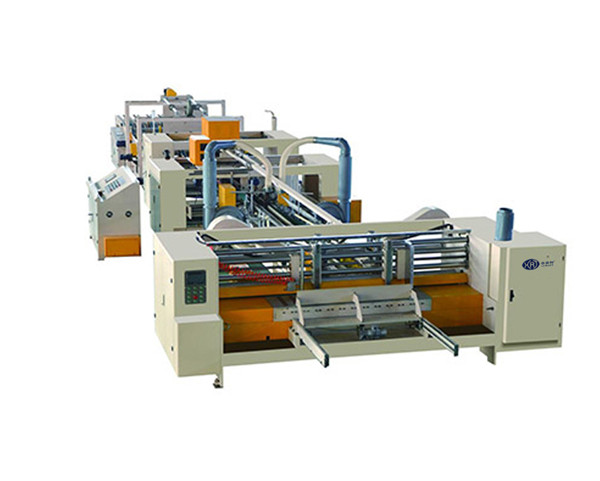

Automatic carton stitching machine

Automatic carton stitching machine

Carton stitching machine

Automatic carton stitching machine

|

Maximum(A+B)*2 |

3000mm |

The minimum length A |

250mm |

|

Minimum(A+B)*2 |

900mm |

The maximum height D |

1150mm |

|

Maximum(C+D+C) |

1200mm |

The minimum height D |

250mm |

|

Minimum(C+D+C) |

350mm |

Nail tongue width E |

35-40mm |

|

The minimum roll cove C |

25mm |

Mechanical length |

19000mm |

|

The biggest shake cove C |

560mm |

Machine width |

4450mm |

|

The maximum width B |

1320mm |

Machine weight(T) |

25 |

|

the minimum width B |

200mm |

Speed(nail/min) |

800 |

|

The biggest length |

1320mm |

order |

1-99 |

|

Nail distance |

30-80 |

Nailing speed |

120m/min |

|

Sticky box speed |

200m/min |

Power(KW) |

60 |

The function and characteristic

With the expansion of business scope,Shandong RiNo International Trade Co., Ltd quickly moves forward to the world and becomes an export-oriented company that integrates production and trade, includes paper packaging products, corrugated packaging machinery equipment, packaging product manufacturing equipment & consumablessuch as Corrugated Cardboard Machine, Printing Machine, Folder Gluer Machine, Automatic Die-cutting machine, Iron Wire and many other products,providing a full range of services from product to technical support.

The paper feeder

Paper feeding part adopts frequency conversion timing belt, vacuum adsorption front, equipped with side flapping device, ensure that the feed is not skew.

The folder part

The folding characteristics is mounted with creasing wheel, carries on second time of creasing. This makes the folding of the carton more beautiful. This machine before stitching box in the folded part have a shaping device, folding the carton before stitching, ensure there is no scissors difference.

The correction device

The correcting section adopts the servo motor to correction , then synchronous belt transport the box into stitching section, ensure no scissors difference.

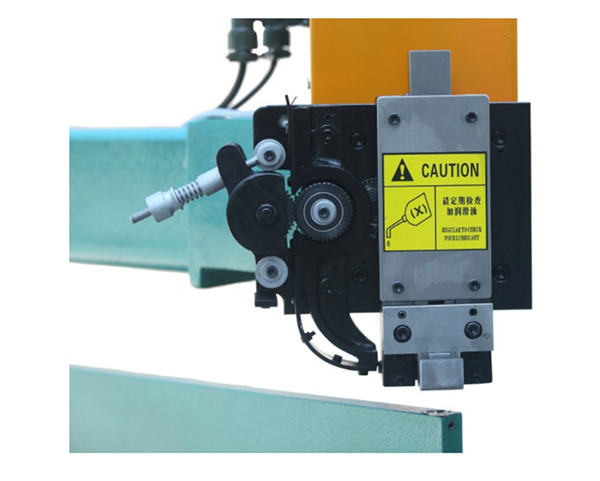

The stitching box part

Stitching head adopts special materials, durable and not easy to damage speeds up to 800/1000 nails per minute, the machine features is that the head adopt servo motor direct drive, speed is stable and accurate. Can do single nail, double nails, head and tail stitch, strengthening the middle stick operation. A nail line using 2 spools 20 kilograms of automatic wire feeding, reduce the time for changing wire spool.

Nail head parameter:

|

Nail head speed |

800 nail/min |

|

The minimum thickness of the board |

4mm |

|

The maximum thickness of the board |

12mm |

|

U nail internal width |

12mm |

|

Flat wire specifications |

17#(2.0 x 0.75) |

|

Nail box inclination |

45 |

|

The minimum distance of nailing |

30mm |

|

The motor power |

12kw |

在线联系供应商

Other supplier products

| Packing Machine-PE | Packing Machine-PE bundling/strapping Machine Machine parameters: The biggest bundle size 1000mm x 800mm The min. bundle s... | |

| Automatic feeding flexo printer with slotter | Automatic feeding flexo printer with slotter Printing Machine Chain-drive feeder printing machine Model Area of valid printing ... | |

| 3/5/7 ply corrugated paperboard production line | 3/5/7 ply corrugated paperboard production line Corrugated cardboard production line 3/5/7 ply corrugated cardboard line U-V5B hydraulic mill ro... | |

| Semi-automatic carton folder gluer machine | Semi-automatic carton folder gluer machine Folder gluer machine Carton folder gluer machine Model UG3-2800 2800mm ... | |

| Manual high speed corrugated carton stitching machine | Manual high speed corrugated carton stitching machine Carton stitching machine Semi automatic stitching machine Machine parameters: mod... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |