Packaging Machinery Manufacturer

Our product line contains a die-cutting machine, film lamination machine, folder gluer machine, greyboard slitting machine, paper bag machine, window patching machine, flute lamination machine, carton forming machine, and many other products. As a product packaging printingfactory, we are able to use sheet-fed, paper rolls and corrugated paper to provide specialized and personalized packaging production solutions with high precision, high speed, and high automation for customers in the fields of food packaging, electronic packaging, daily chemical packaging, cosmetic boxes, medicine boxes, office supplies and so on. We are committed to continuously improving production efficiency and packaging technology level by promoting technological progress and service innovation in post-press packaging machinery chinamanufacturing to achieve sustainable and high-quality development of the industry.

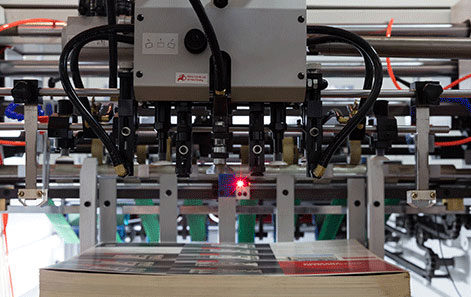

Continuous Quest for Our Packaging Machinery

Our packaging machinery in china is based on international advanced technology, has high stability, high safety performance, high precision of the finished product, which is widely used in paper packaging, such as paper box, product packaging printing and so on.

Packaging Machine Manufacturing-FAQs

Q

Can the machine be customized as our need?

A

Surely our machine can be customized as your need.

Q

Could you print our company LOGO on the nameplate and package?

A

Yes, all the packaging printer machines and post press machinescan be printed with your LOGO.

Q

Can l visit your factory?

A

By all means, we warmly welcome your arrival. Before you take off from your country, please let us know. We will show you the way and arrange a time to pick you up if possible.

Q

Do you have QC department?

A

Yes, we have 6 QC persons.

Q

What is the delivery time for mass production?

A

The mass production of packaging printing and post-printing machine is about 45 days.

If you want to know more about packaging printing machine price, please contact us.

As a packaging machinery company, we will provide more kinds of related products for sale, if you have needs, please leave us a message.

在线联系供应商

Other supplier products

| High Speed Paper Cup Fan Punching Machine | It is suitable for multi-colour printing of roller paper, tinted with high precision, and high speed cutting and stripping at the same time. It i... | |

| Automatic High-speed Multi-function Folder Gluer Machine | The multi function packing machineadopts a lightweight design, reducing noise, improving equipment handling, reliability. Modular design, perfec... | |

| 1050D Automatic Deep Embossing Die Cutting Machine | We designed 1050D Automatic Deep Embossing Die Cutting Machine, which is the greatest research and development and manufacturing of new equipment w... | |

| 1050 ES Automatic Stripping Die-Cutting Machine | As one of the professional packaging machinery suppliers, Our product line covers a wide range of products including die-cutting machine, film lami... | |

| Window Patching Machine | Window Patching Machinefor Sale GROWING has been specializing in manufacturing window patching machines for years and has rich management experien... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |