Automatic carton folder gluer stitching machine

Automatic carton folder gluer stitching machine

A. Paper feeding department:

Adopt SiGreen high wear-resistant suction belt, each can control the size of the air volume separately. To ensure the stability of adsorption, the machine adopts pneumatic buffer plastic shaft feeding method to effectivelysolve the problemof low compression resistance of cardboard with line, the paper feeding part adopts double drive servo separation before and after the paper feeding, while thepreloading synchronous automatic adjustment, each cardboard before and after individual precise transmission, more accurate positioning.The front baffle of the feeding part can be adjusted by electric power, and the front feeding part can be adjusted byelectric power. It is convenient and fast to meet the demand of paper supply of various specifications.

B. Wire touching part:

Thepaperboard is sent from thepaper feedingdepartment to theline touching department.Itis a feature ofour company's nailsticking machine.The originalpaperboardis often not ideal after thepreviousprocess,whichaffectsthequalityofproducts.Theline touching partis to deal with the originalrollingpart by the method oflinetouching again, so asto achieve a better folding effect,and can wellcontrolthe size of the carton after sticking nails.The keydata is obtained from countless tests and tests.The pressure of theline touching can be adjusted according tothe thickness and materialofthe paperboard. Therefore,theline touchingpart has the advantagesof reasonable structure,novel design, practical convenience and obvious effect.

automatic folder gluer stitching machine

C. Folding part:

Linkage with the paper feeding part, frequencyconversion speedregulation, folding and paper feeding partpressline synchronous adjustment. Imported porous beltconveyor cardboard, automaticfolding,the whole process of adsorption,effectively avoid weight box, film box, glazing box and other cardboard in the work of the phenomenon of skew skid pile of paper, make the machine more stable and efficient.

D.Calibration Department

1. The machine has a shapingdevice before the nailingbox attheback ofthe foldingpart.Before the nailingbox,thefoldedcartons willbe adjusted and patted againto ensure that the nailedcartons have no scissors.

2.The calibrationpartisdriven byservo motor.

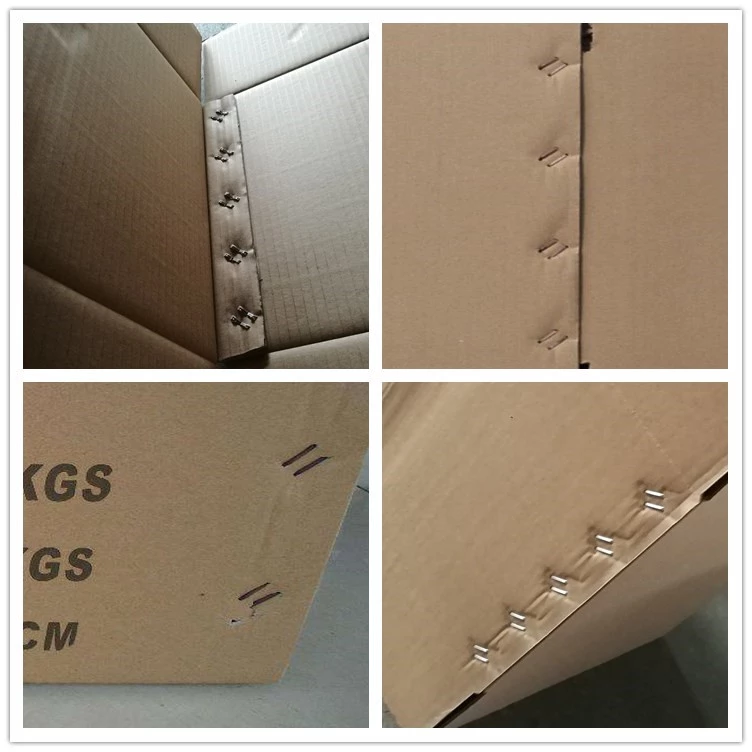

E. department:

1.Interconnect with theline touching part,frequency conversion speed regulation, add each molding wheel. roll the originalline acain

2.The machine is characterized by direct drive of servo motor with stable and accurate speed.

3. The stitchinglineadopts 2plates of2kgflat wire automatic wire feedingdevice to reduce the number of wire changingandimproveproductionefficiency.

4 This machine can beused for single nail,double nail,strengthen the multi-functionoperation of the carton.

5 nailspeedper minute upto 700 nails/minute.

F. Counting and stacking output

Completethe carton,clap,count,stack and send out the whole dozenautomatically.

We also have may other machines:

Corrugated carton stitching machine,automatic box stitching machine,semi automatic stitching machine,double piece box stitching machineand so on.

Welcome to send an for the productdetails.

1. OEM service are available.

2. Trade Manager online, also contact by Email.

3. To solve problems by pictures/videos.

4. Engineers are available service abroad.

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling fromthe very small thing(even a small screw we will choose the best quality) from thebeginning.

在线联系供应商

Other supplier products

| Corrguated carton partition assember machine | Features and functions of Full automatic partition assembler :1, suitable for all kinds of carton partition plate, block automatic insertion;2, e... | |

| full automatic nail machine for corrugated box | ♦The machine adoptsJapanese yaskawa, mitsubishi brand servo drive, precise andaccurate,the mechanical transmission part is less, can effectiv... | |

| automatic spiral kraft paper core making machine | automatic spiral kraft paper core making machine We are a foreign trade sales manufacturer integrated company, we have specialized in doing paper ... | |

| automatic flexo printing die cutting slotting machine | 1. Die cutting shaft alignment gauze shaft alignment makes the machine run more easily. 2. The circumferential direction of the master roll and th... | |

| semi automatic stitching machine | ♦ Mitsubishi dual servo drive, precision, mechanical transmission part reduction. can effectively reduce the mechanical failure rate. &diams... |

Same products

| Full-automatic Spring Packaging Machine ZF-TH700 | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Mainly used for organ packaging of textured paper. Full-automatic Spring Packaging Machinecan be ... | |

| Full-automatic Pillow Packaging Machine ZF-Z450X ZF-Z600X | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | Z450X Z600X mainly used for single-roll packaging of OPP tape, double-sided tape, foam adhesive, ... | |

| Cylinder Tea Box Shrink Packaging Machine | 卖方: Shenzhen Zhongfu Packaging Technology Co., Ltd | This cylindrical tea box shrink packaging machineis very suitable for heat shrink packaging of cy... | |

| MASTERCUT 106 PER - высекальный пресс Autoplaten | 卖方: 杭州四色印科技有限公司 | ||

| Sticker equipment | 卖方: 杭州四色印科技有限公司 | Supply 350 fully automatic high-speed die-cutting machine EVA foam PET protective film multifunct... |