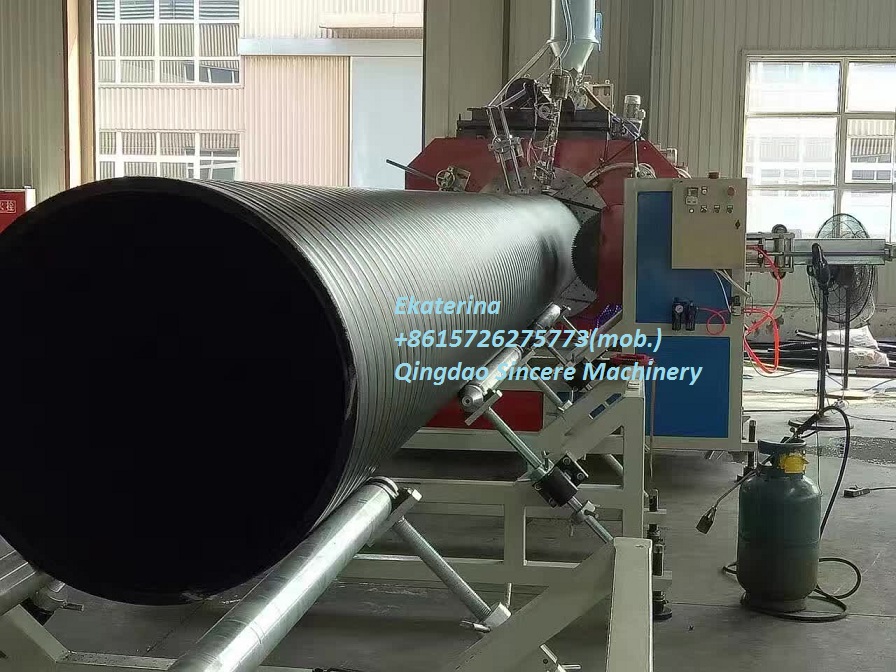

HDPE高密度聚乙烯结构壁内肋增强波纹管排水排污管缠绕管挤出生产线

HDPE高密度聚乙烯中空壁结构壁内肋增强波纹管市政排水排污管塑钢缠绕管挤出生产线 200-3000mm

HDPE structured-wall corrugated plastic pipe manufacturing machinery.

HDPE Hollowness wall winding pipe making machine.

**200-3000mm

**SN2, SN4,SN8,SN12.5, SN16

Part 1: HDPE Rib Reinforced Corrugated type Spiral Pipe production line

1. HDPE Rib Reinforced Corrugated type Spiral Pipe production lineis a kind of new generation high performance.

plastic spiral pipe line for large diameter buried drain pipe according to hollow wall winding pipe

production technology with the intellectual property. It can produce pipe size from Ø200~Ø2400mm

which is widely used in fields of civil water drain, wastewater drain.

2. The pipe could also be made by the recycled polyethylene material. These properties make it superior

advantages compared with other kinds of drainage pipe.

1) The investment is lower and the automatic control system is easy for operation and maintenance.

2) Adopt winding method by winding the semi-round two side circle profile

3) The inner PE-layer is Composited with the U-type pipe in melting condition. And they will never been

delaminated after spraying cooling forming, with good adhesion effect.

4)Adopting Electric-magnetic heating system which can save 40% to 60% electric power.

5)All Electric Part (breaker/motor/INCKO/Inverter) is Siemens/Schneider/Omron

6)Production Speed is 1-20m/min.

7)Max. Pipe Size: 3000mm.

3. The features of PE Spiral Corrugated Pipe:

1) Light weight-per-meter

2) Belling link, tight cementation

3) Pressure against, high strength

4) Anti-frozen and long service life (50 years )

5) Convenient construction

Part 2:HDPE large diameter hollow wall winding pipe production line

1. HDPE Large diameter winding pipe(diameter from 200mm-3000mm) has high ring stiffness and high brunt intensity with "H" structure. It can be used for approximate 50 years and has many advantages such as low cost assembly and easy operation, with standing pressure, corrosion resistant such as acid, alkali and salt etc. It is becoming as areplacement of cement pipe and cast iron pipe nowadays. It is being widely used as sewage and drainage pipe.

2. HDPE large diameter hollow wall winding pipe machine .

**The HDPE large diameter hollow wall winding pipe extrusion line is designed with advantaged technology and improved based on long time practice experience. Diameter range can be 200-3000mm.

**Our machine is featured with comfortable operation and high performance/price ratio.

**Due to our special design, it is very convenient in transportation and installment.

**We also developed energy saving method to save energy consumption in large diameter hollow wall winding pipe extrusion.

**By adopting two sets of high efficient extruders, the output capacity is big. Our winding pipe extrusion line can make pipe with ring stiffness 4, 8, 12KN/m2. All parts precisely designed and manufactured so the whole extrusion line works stably and reliably.

**Special design for easy maintenance.

**The HDPE large diameter hollow wall winding pipe extrusion line is mainly used for producing large diameter hollow wall winding pipe.

3. Technical parameters:

| Model | XSPG-800 | XSPG-1200 | XSPG-1600 | XSPG-2200 | XSPG-3000 | |||||

| Extruder | XSSJ-65*30 | XSSJ-50*30 | XSSJ-65*33 | XSSJ- 50*30 |

XSSJ-80*33 | XSSJ- 50*30 |

XSSJ-80*33 | XSSJ-65*33 | XSSJ- 100*33 |

XSSJ- 65*33 |

| Output capacity | 250kg/h | 120 kg/h | 300 kg/h | 120 kg/h | 500 kg/h | 150 kg/h | 750 kg/h | 250 kg/h | 900 kg/h | 300 kg/h |

| Pipe diameter | 200-800 mm | 400-1200 mm | 800-1600 mm | 1200-2200 mm | 2000-3000 mm | |||||

| Production speed | 2-16 m/h | 2-12 m/h | 1-6 m/h | 0.5-5 m/h | 0.3-3 m/h | |||||

| Installed Power | 180 kw | 250 kw | 300 kw | 400 kw | 500 kw | |||||

在线联系供应商

Other supplier products

| 塑料回收造粒生产线,塑料造粒机,pp、pe,pet造粒机,拉条造粒,水环造粒 | PP/PE塑料造粒生产线200kg/h,250kg/h 300kg/h,500kg/h 。PP PE ABS PET PMMA 塑料回收设备造粒线。 塑料PP PE ABS PET PMMA的双阶造粒线。 造粒生产线产量:从150kg/h到1000kg/h。 装机容量:60kW-800k... | |

| 高密度聚乙烯(HDPE)中空壁大口径缠绕管波纹管排水排污管生产设备 | HDPE高密度聚乙烯中空壁结构壁内肋增强波纹管市政排水排污管塑钢缠绕管挤出生产线 200-3000mm **HDPE large diameter hollow wall winding pipe production line**HDPE Structural wall winding p... | |

| 三层pp pe ppr管复合管材挤出生产线 | ppr管材挤出生产线。 三层ppr供水管挤出生产线。 三层hdpe供水管材挤出生产设备。 塑料pp ppr pe管材挤出生产线。 管材直径:16-1600mm。 管材挤出生产线组成: 原料真空上料机,干燥料斗,单螺杆挤出机,三层共挤机头,真空定径喷淋水箱,牵引机,切割机,堆料架,破... | |

| MBBR浮游生物填料挤出生产设备 | 青岛新斯尔机械设备有限公司专业生产PE/PP环保污水处理生物填料设备,开发出一出四、一出六污水净化生物悬浮填料生产线。 新型专业PE/PP环保污水处理生物填料设备,一出四、一出六污水净化生物悬浮填料生产线自动化水平高,出料均匀,一出六的设备改进更是提高了设备出产率,生产的产品应用到废水和中水生... | |

| 3PE FBE 钢管防腐涂覆生产线 | 3PE FBE 钢管内防腐涂覆生产线。 3PE FBE 钢管外防腐涂覆生产线。 1.PE 3PE 2PP 3PP燃气管道防腐涂层钢管。 2.主要描述: 防腐涂料在钢管上的应用是采用环氧粉末和韧带层的防腐涂层,聚乙烯包裹或涂层而成,这种钢管防腐技术不仅在国内外得到广泛应用,常用于天然气,油,... |

Same products

| WPC 木塑室外地板挤出生产线 | 卖方: Qingdao Trusty Plastic Machinery Co.,Ltd | 木塑复合材料(WPC)与木材不同,具有更高的耐腐蚀性和耐温性。其低残余湿度和多孔结构也赋予了它更高的强度。凭借这一特性,WPC地板(或甲板)被广泛应用于各种休闲场所的建造,如夏季咖啡馆、凉亭和门... | |

| High Efficiency Series of Screw Extruder | 卖方: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | 卖方: Nanjing ChNanjing Chuanqi intelligent Equipment Co., Ltd.uanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | 卖方: Nanjing ChNanjing Chuanqi intelligent Equipment Co., Ltd.uanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | 卖方: Nanjing ChNanjing Chuanqi intelligent Equipment Co., Ltd.uanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |