Plastic Extruder For Thermoplastic Elastomer

Mixing Modification of Elastomer——Blending Modification of SBS/SEBS

Applications of Thermoplastic Elastomer:

The English acronym of thermoset extrusionis TPE. In the Chinese market, TPE refers to SBS/SEBS blending modification materials. Because SBS/SEBS elastomer usually has a high viscosity and is difficult to be directly processed, TPE thermoplastic elastomer material (TPS) is prepared by blending SBS/SEBS with plasticizer oil, reinforcing resin, compatibilizer, functional assistant, compatibilizer and so on. Compared with SBS/SEBS, the modified TPE has a lower viscosity, higher plasticity, easier processing and molding. It also has a wide range of adjustable hardness and physical properties. And it does not need vulcanization, can be recycled to reduce costs and other characteristics, so the application field is more extensive. It is mainly used in all kinds of seals, automotive interiors, glue-coated materials, all kinds of pipe fittings, wires and cables, etc.

According to different hardness requirements, SBS or SEBS blending modification adjusts the proportion of SBS/SEBS, PP, filler and filling oil. The increased rigidity of PP, SBS/SEBS and filling oil can improve flexibility.

Features of thermoplastic extrusion:

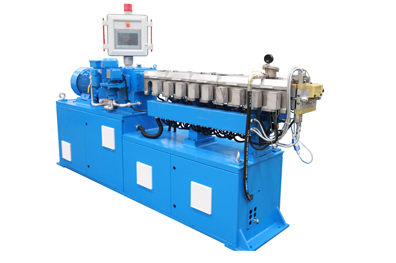

Design of screw barrel with a large aspect ratio. Large aspect ratio L/D=48:1-52:1 provides longer residence time, which is beneficial to the melting of resins and elastomers, homogenization and mixing of filling oil and polymers.

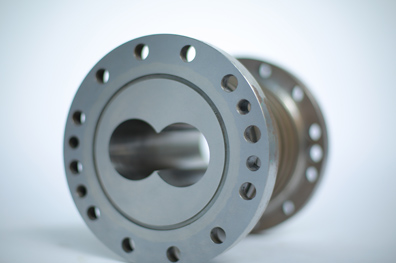

High-precision screw and barrel design. The clearance between screw and barrel is small, the dimension accuracy is high, and the screw structure is optimized to effectively complete the mixing process of resin melting, filler dispersion and filling oil homogenization.

Cutting method. At present, the underwater granulation device at home and abroad has been continuously improved, which basically meets the requirements of different hardness, so underwater granulation is adopted.

Mixing modification of elastomer——Description of TPV dynamic vulcanization process

Applications of Thermoplastic vulcanizate:

Thermoplastic vulcanizate is referred to as TPV in short. It is a process that combines some properties of vulcanized rubber with processing properties of thermoplastic plastics. At present, the common components are PP, EPDM, filler, filler oil, crosslinking agent and processing aids. The so-called dynamic vulcanization refers to the simultaneous vulcanization (crosslinking) and melts dispersion of rubber. In the continuous phase of the vulcanized rubber phase uniformly dispersed resin, the particle size of the dispersed phase is 1-2 micron under the appropriate temperature field and shear field, which puts forward very high requirements for the blending equipment and preparation technology. TPV products are mainly used in all kinds of seals, soles, pipes, wires and cables.

Features of twin-screw extruder:

The twin screw extrusion machine with high speed and high torsion is adopted. High torque can withstand larger loads and adapt to the characteristics of high strength of vulcanized rubber melt; high screw speed provides a higher shear rate, which disperses vulcanized rubber into small rubber particles and evenly disperses in resin.

Screw barrel with large aspect ratio and multi-way metering feeding. Large aspect ratio L/D=48:1~52:1 provides longer residence time, which is conducive to completing the melting homogenization, vulcanization and dispersion of complex mixing process. At the same time, it is equipped with multiple groups of metering feeders to feed resin, rubber, filler, filling oil and crosslinking agent into the barrel step by step.

High-precision screw and barrel design. The clearance between screw and barrel is small, the dimension accuracy is high, and the screw structure is optimized. The melting process of resin and the homogenization process of filling oil is effectively completed, and the dynamic vulcanization process is completed by shearing and dispersing components.

Cutting method. At present, the underwater granulation device at home and abroad has been continuously improved, which basically meets the requirements of different hardness, so underwater granulation is adopted.

The above introduction is a one-step dynamic vulcanization process, which is suitable for the production conditions with a stable formulation ratio. In actual production, due to the different requirements of product performance, the proportion of each component in the formulation varies greatly, and the proportion and degree of vulcanized rubber are also quite different, so the two-step dynamic vulcanization process will have stronger applicability.

Two twin-screw extruder production lines:

The upper twin screw mixes PP, EPDM, filler and a small amount of filling oil evenly and granulates.

The lower-order twin-screw mixes the homogeneous polymer, most of the filling oil and crosslinking agent to complete the crosslinking of EPDM and disperse it evenly.

As one of the extruders manufacturers, we provide twin screw extruder, downstream extrusion equipment, china plastic extruderand etc. Want to know more? Contact us.

在线联系供应商

Other supplier products

| AKW Series Water Ring Pelletizer | For some materials such as elastomers with low hardness or easy adhesion, it is recommended to use a water ring pelletizerfor granulation. After ex... | |

| Barrels | The body of the basic grade barrel is made of 45 # steel. The liner of the barrel is made of basic alpha-101 bimetallic material. The high-grade... | |

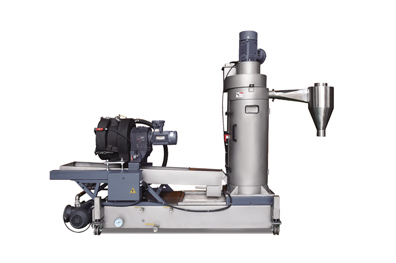

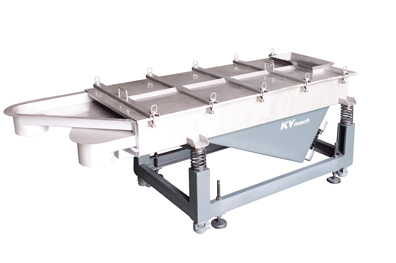

| Material handling auxiliaries | Material handling auxiliaries include material storage and transportation, mixing and metering, transportation and special treatment to the main eq... | |

| Screw Element | All component materials are supplied by domestic first-line brands or European professional materials suppliers of twin-screw plastics machines. An... | |

| HK Extruder for Small Batch Production | HK36 and HK53 small plastic twin-screw extruders are very competitive equipment models for small batch production scale, especially for the Color M... |

Same products

| WPC 木塑室外地板挤出生产线 | 卖方: Qingdao Trusty Plastic Machinery Co.,Ltd | 木塑复合材料(WPC)与木材不同,具有更高的耐腐蚀性和耐温性。其低残余湿度和多孔结构也赋予了它更高的强度。凭借这一特性,WPC地板(或甲板)被广泛应用于各种休闲场所的建造,如夏季咖啡馆、凉亭和门... | |

| High Efficiency Series of Screw Extruder | 卖方: Shandong Decao Machinery & Equipment Co., Ltd | Extruded Snacks Making Machineis a complex system that integrates multiple key equipment and proc... | |

| Benchtop Extruder | 卖方: Nanjing ChNanjing Chuanqi intelligent Equipment Co., Ltd.uanqi intelligent Equipment Co., Ltd. | Key Features of Benchtop Extruder() Precision Control: Benchtop Extruder is designed to provide m... | |

| SHJ Series Twin Screw Extruder | 卖方: Nanjing ChNanjing Chuanqi intelligent Equipment Co., Ltd.uanqi intelligent Equipment Co., Ltd. | The SHJ Series Twin Screw Extruder() represents a remarkable evolutionary step in the field of ex... | |

| Underwater Pelletizer | 卖方: Nanjing ChNanjing Chuanqi intelligent Equipment Co., Ltd.uanqi intelligent Equipment Co., Ltd. | The Underwater Pelletizer(), a technological marvel in the polymer processing sector, has redefin... |