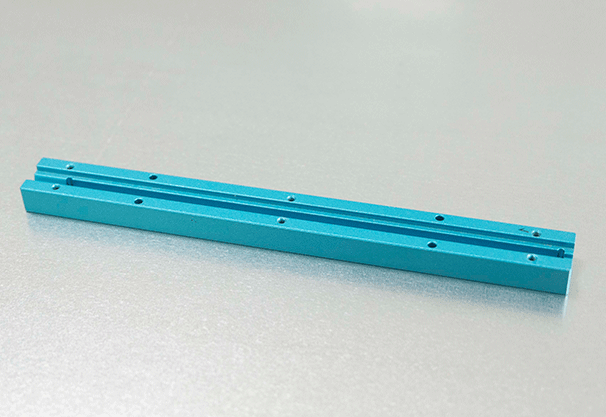

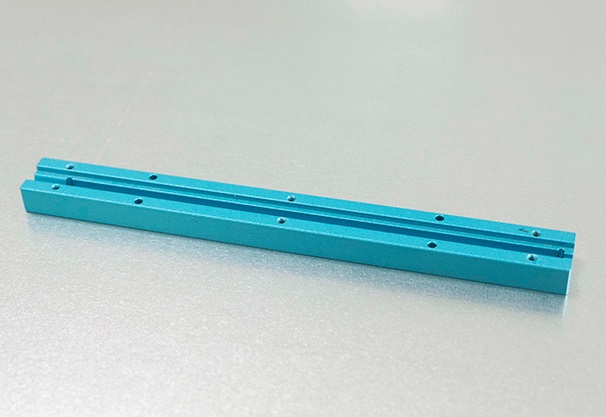

CNC Metal Machining Parts

Packson is a contract manufacturer specializing in nylonCNCMilling, CNC Turning, CNC Drilling services in China. We are able to manufacture plastic machining pieces and stainless steel cnc machining partswith various materials. POM, ABS, HDPE, Nylon, PLA, PC, PEEK, PMMA, PP , PTFE , etc. Full support different requirements of various surface treatments , tight tolerance.

Packson CNC Metal Parts Machining Capabilities

|

Machining Process: |

Drilling, Thread Milling, Broaching, Tapping, Spline, Reaming, Parting/Cutting, Profiling, Facing, Turning, Threading, Internal Forming, Pocketing, Knurling, Countersinking, Boring, Counter boring, Gear Hobbing |

|

Machining Surface Finishing |

Sandblasting, Brushing, Lapping, Anodizing, Laser etching, Painting and Plating |

|

Tolerance: |

± 0.0002 in, ±0.005 mm |

|

Ability: |

Ability to service the micromachining market with a specialty in small batches, fast processing work |

|

Machinery Axis: |

3-Axis,4-Axis, 5-Axis |

|

Industry Standard: |

ASNI, ASME, ASTM, ISO, Mil-Spec, RoHS |

Available Materials For Brass CNCMachining Parts

|

Type |

Alloy (parts) |

Features and characteristics |

Application (Industry) |

|

Aluminum |

6061 |

Upgrade corrosion resistance on 7075 |

|

|

6061 - T6 |

All-purpose aluminum with medium strength. |

Camera lens mounts, Electronic hardware, Couplings, Marines fittings, Prototypes, Aircraft fittings and Hardware |

|

|

Good forming ability, weldability |

|||

|

It's made of magnesium and silicone. |

|||

|

7075 |

Greater strength than aluminum 6061. |

||

|

Strong resistance to fatigue. |

Fuse parts, Worm gears,Keys, Regulating valve parts, Aerospace and defense applications;Bike frames,Aircraft, Meter shafts and gears, Gears and shafts, Missile parts, |

||

|

Brass |

260 |

Strong resistance to corrosion |

Fittings, Commercial products, Contacts, Aerospace and Electronic hardware |

|

Resists most of the chemicals. |

|||

|

Plate stock |

|||

|

Copper |

C101 |

Electro copper without oxygen |

Automotive, General engineering, Domestic appliances, Electrical contacts, |

|

High electrically conductive |

|||

|

The good corrosiveness in most environments |

|||

|

Low against acids, halogenic sulfides and ammoniacal solutions. |

|||

|

Plastics |

Ceramic Peek |

Great dimensionality, good shock resistance. |

Test sockets, switches, connectors |

|

Rigidity a minimal level of creep, better shock resistance. |

Connector, Switches, Test sockets |

||

|

Excellent machinability |

|||

|

PVC |

Exceptional chemical resistance and corrosion resistance. |

Used for anything, from building profiles to medical devices, from roofing membranes to credit cards, from kid’s toys to pipes for water and gas |

|

|

Great resistance to flame. |

|||

|

Low cost |

|||

|

Nylon 6/6 |

Nylon for general use |

Bearings,Insulators, |

|

|

Good flame strength and good performance machining |

|||

|

Hastelloy |

C-276 |

Great mechanical strength, above all at high temperatures |

Chemical reactors, Pipes and valves in chemical industry,Pressure vessels of some nuclear reactors,Distillation equipment, |

|

High resistance corrosion and oxidization |

|||

|

Alloy Steel |

4041 |

Good resilience and strength |

Applications of higher loads requiring the force of an alloy. |

|

Direct hardening and heat treatment |

|||

|

Harder than CR 1018 |

|||

|

Steel |

1018 |

Low carbon standard steel |

Rivets and parts in need of heavy welding |

|

Great forming ability and welding ability |

|||

|

Case harden only |

|||

|

12L14 |

Great machinability |

Endless commercial products; probably more pounds used in turned products than any other bar stock |

|

|

Case harden only |

|||

|

1137 |

Higher carbon, higher strength |

Higher stress applications, gears, shafts, studs |

|

|

Direct hardening |

|||

|

Stainless Steel |

304 |

The most widely used stainless steel |

Household and industrial applications: screws, machinery parts, car headers, food-handling equipment, |

|

Low carbon |

|||

|

Better welding ability and forming ability |

|||

|

316 |

Improved corrosion and chemical resistance than 304 |

Aerospace, Medical implants and surgical instruments, |

|

|

Improved resistance to cracking and pitting |

|||

|

416 |

Free machining |

Applications that need less corrosion resistance, more hardness, or lower cost |

|

|

Less corrosion resistant than 300 series |

|||

|

Can be heat treated |

|||

|

17-4 PH |

Higher magnetism than 304 and 316 stainless steel |

Medical, aerospace, applications needing corrosion resistance and hardness |

|

|

Oxidation and corrosion resistance |

|||

|

Titanium |

Ti-6AI-4V |

Light-weight and high strength |

Medical implants, Jewelry, Aircraft industry, |

|

High temperature and corrosion resistance |

Why Choose Packson For CNC Machining Metal Parts?

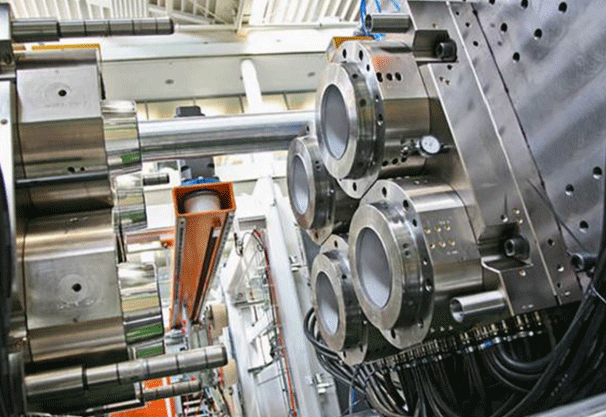

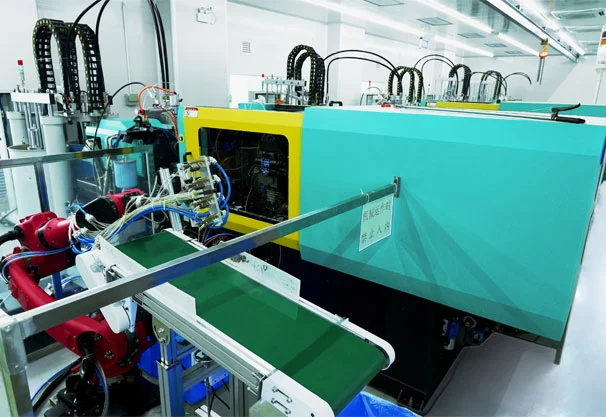

Advanced CNC Machining Equipment & Materials

With precise peek CNC machiningcenters imported from Taiwan and Japan, we are able to manufacture turned, machined and drilled parts with a wide range of plastic and metal materials. Meanwhile, outstanding software such as Autodesk PowerMill and cutters which are imported from Japan, provide the foundation for making excellent CNC machining metal parts products.

Full testing and verification of Raw Material of CNC Machining Metal Parts

Chemical and physical analyses of all raw materials in the factory are carried out by means of advanced scientific equipment. Nobody else provides such a complete quality control report of the materials, ensuring peace of mind with certificates of conformity on demand. To make sure, all ongoing CNC machining metal parts are manufactured according to your design specifications via our inspection during manufacture. That's why our CNC milling services are a leader in the industry.

Smart charging for every CNC machining project

We care about your time and money. We don't need a minimum order volume or a minimum monetary value to provide you with full flexibility based on your schedule. With experienced project stock, we provide quick and precise quotations without any speculation.

Weekly Track Record of Your CNC Machining Metal Parts

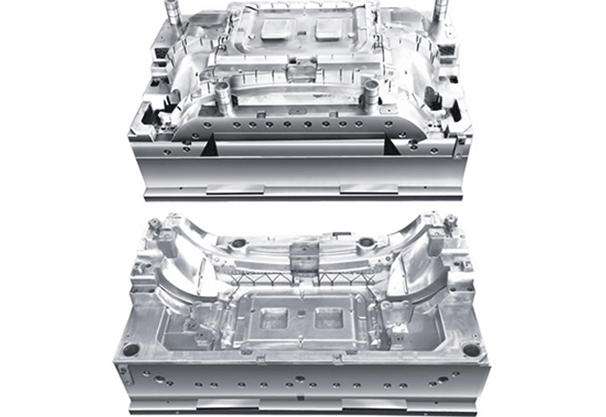

As one of injection moulding manufacturers, we provide track record for the whole project from the beginning of CNC machining metal parts design, to the selection of material,to the running of first prototype, to the running of final production. To let you supervise the project easily.

A complete series of finishing CNC machining metal parts services

As we have known, there are many cosmetic finishing before the clients receive their parts. We are able to provide sandblasting,brushing,lapping,anodizing, laser etching, painting, and plating for our clients. 100% meet customer requirements of CNC machining metal parts.

If you want to know more details of lsr silicone molding, please visit our website.

在线联系供应商

Other supplier products

| CNC Metal Machining Parts | Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling services in China. We are able to manufacture plastic mac... | |

| 2K Injection Molding | 2k injection molding is one type of injection mold. 2k molding is also named as two shot molding, double shot molding, double-color mold, Multi-mat... | |

| 2K Injection Molding | 2k plastic injection mouldingis one type of injection mold. 2k two color moldingis also named as two shot molding, double shot mold, double-color m... | |

| CNC Metal Machining Parts | Packson is a contract manufacturer specializing in CNC Milling, CNC Turning, CNC Drilling services in China. We are able to manufacture plastic mac... | |

| Medical Plastic Parts | Project Management To be a qualified medical plastic components manufacturer, the most advanced technology and continuous compliance and certifica... |

Same products

| Silicone Rubber Injection Molding | 卖方: Packson Mold Co.,Ltd | Packson's state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped ... | |

| Prototype Injection Mould | 卖方: Packson Mold Co.,Ltd | Packsonmold is a company that provides high-quality prototype services, including 3D printing, CN... | |

| Precision Injection Molding | 卖方: Packson Mold Co.,Ltd | At Packson, we specialize in manufacturing custom precision mold partsand machined parts that mee... | |

| Overmolding Injection Molding | 卖方: Packson Mold Co.,Ltd | Overmoldingmold is made of overmolding injection molding processwhich is a special injection mold... | |

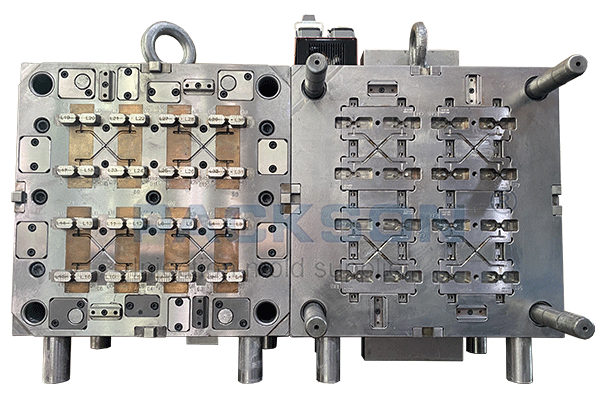

| Multi-cavities Injection Molding | 卖方: Packson Mold Co.,Ltd | Multi cavity mouldis an injection mold that has more than one cavity. The shape of each cavity is... |