Sm2Co17 Magnets

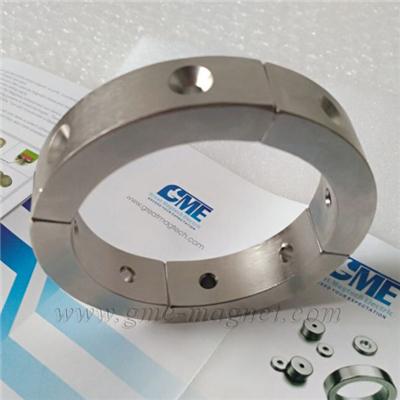

Samarium Cobalt magnets: Samarium cobalt Magnet / SmCo Magnet,Website:, a type of rare earth magnet, is a permanent magnet and strong magnet which is made of an alloy of samarium cobalt.They are generally ranked similarly in strength to neodymium magnets, but have higher temperature ratings and higher coercivity and excellent thermal stability, resistant to corrosion, resistant to demagnetizing influences. Such high resistance makes it ideal to use the SmCo magnets in medical and the most demanding motor applications.Manufacturing MethodsSamarium cobalt Magnets / SmCo Magnets are manufactured in the following forms:Sintered - fine SmCo powder is compacted in a die mold and then sintered, fusing the powder into a solid material. There are two forms of pressing for Samarium cobalt Magnets / SmCo Magnets: Die pressing (which involves a hard die into which the powder is placed and then pressed), and isostatic pressing (involving a special "rubber" die into which powder is placed and then pressed with equal force in all directions on the powder). Die pressed parts are smaller than isostatically pressed parts. Although the magnetic properties of isostatically pressed parts are higher, the uniformity of magnetic characteristics is usually lower than that of die pressed parts. Sintered parts usually need some finish machining in order to meet final tolerances.Sintered Samarium Cobalt magnets exhibit magnetic anisotropy, meaning they can only be magnetized in the axis of their magnetic orientation. This is done by aligning the crystal structure of the material during the manufacturing process.Compression Bonded - this is a technique whereby a special form of SmCo powder is blended with a plastic carrier material, die pressed and then heated. Parts made in this way can be of complex shapes and come off the tool with close tolerances, requiring no further finish machining. They have lower energy products than sintered materials - currently in the range of 15 MGOe.Machining & MagnetizationSamarium Cobalt magnets offer strong resistance to demagnetization. All Samarium Cobalt magnets cannot be formed with conventional drilling, turning or milling processes, and must be ground before they are magnetized. Additionally, large or complex assemblies are usually magnetized prior to assembly. Standard tolerances for Samarium Cobalt magnets are +/-0.1mm for ground dimensions. Samarium Cobalt magnets manufacturing processing:Samarium Cobalt Magnets Performance: Samarium cobalt Magnets / SmCo Magnets have maximum energy products (BH max) that range from 16 megagauss-oersteds (MGOe) to 33 MGOe, approx. 128 kJ/m3 to 264 kJ/m3; their theoretical limit is 34 MGOe, about 272 kJ/m3. This magnets can be found in two different grades, Sm1Co5 and Sm2Co17, each one with its specific magnetic behavior.Features include:Samarium cobalt Magnets / SmCo Magnets are hard and brittle and may chip or break if dropped, however, they have high magnetic properties and are available in two series, namely Series 1:5 and Series 2:17.1:5 alloy material1:5 offers 16 MGOe (energy product) to 22 MGOe and is made up of approximately 50% samarium and 50% cobalt. The 1:5 series has a maximum recommended operating temperature of 250°C. SmCo 1:5 magnets require lower field strengths than 2:17 materials to magnetize. In some instances, 1:5 material may be magnetized with multiple poles, provided that a magnetizing fixture is available.2:17 alloy material2:17 offers 24 MGOe to 32 MGOe and is composed of about 25% samarium, 5% copper, 18% iron, 2% hafnium or zirconium, with the remainder being cobalt. The 2:17 series has a maximum operating temperature of 350°C. Special grades of 2:17 are available which can operate to even higher temperatures. SmCo 2:17 requires a higher magnetizing field than alloy 1:5 does, and multiple pole magnetization is sometimes possible, provided that a magnetizing fixture is available.SmCo Magnet Properties:Advantages:-Extremely resistant to demagnetization-high temperature stability (max operating temperatures between 250 °C (523 K) and 550 °C (823 K); Curie temperatures from 700 °C (973 K) to 800 °C (1,070 K)-Expensive and subject to price fluctuations (cobalt is market price sensitive)Disadvantages:-Samarium cobalt magnets can easily chip; eye protection must be worn when handling them.-Allowing magnets to snap together can cause the magnets to shatter, which can cause a potential hazard.-Samarium-cobalt is manufactured by a process called sintering, and as with all sintered materials, inherent cracks are very possible. These magnets do not have mechanical integrity; instead the magnet must be utilized for its magnetic functions and other mechanical systems must be designed to provide the mechanical reliability of the system.Applications of SmCo MagnetsThe magnetic properties decrease of SmCo magnets is rather low with increasing of the temperature. Thus SmCo magnets are rather appreciated in military and aerospace industry, as well as in electro medical field, especially when oxidation or thermal needs become very important. Industrial applications are similar to Neodymium magnets: sensors, loudspeakers, electric motors, instruments, switches etc.Assemblies of SmCo Magnets

Other supplier products

|

|

|

Magnetic Blocks/ Neodymium Block Magnets Magnetic blocks are six-sided magnets with straight sides where all angles are right angles (90°). Opposit... |

|

|

|

Among those famous hot sale machine chucks electromagnetic chuck manufacturers, it is a professional supplier in China, welcome to wholesale hot sa... |

|

|

|

Among those famous n50 electro magnets rare earth powerful magnets cylinder magnets manufacturers, it is a professional supplier in China, welcome ... |

|

|

|

Among those famous white coating magnetic hooks manufacturers, it is a professional supplier in China, welcome to wholesale magnetic fishing, ceili... |

|

|

|

Among those famous arc magnet with countersunk hole generator magnet motor magnet manufacturers, it is a professional supplier in China, welcome to... |

供应产品

Same products