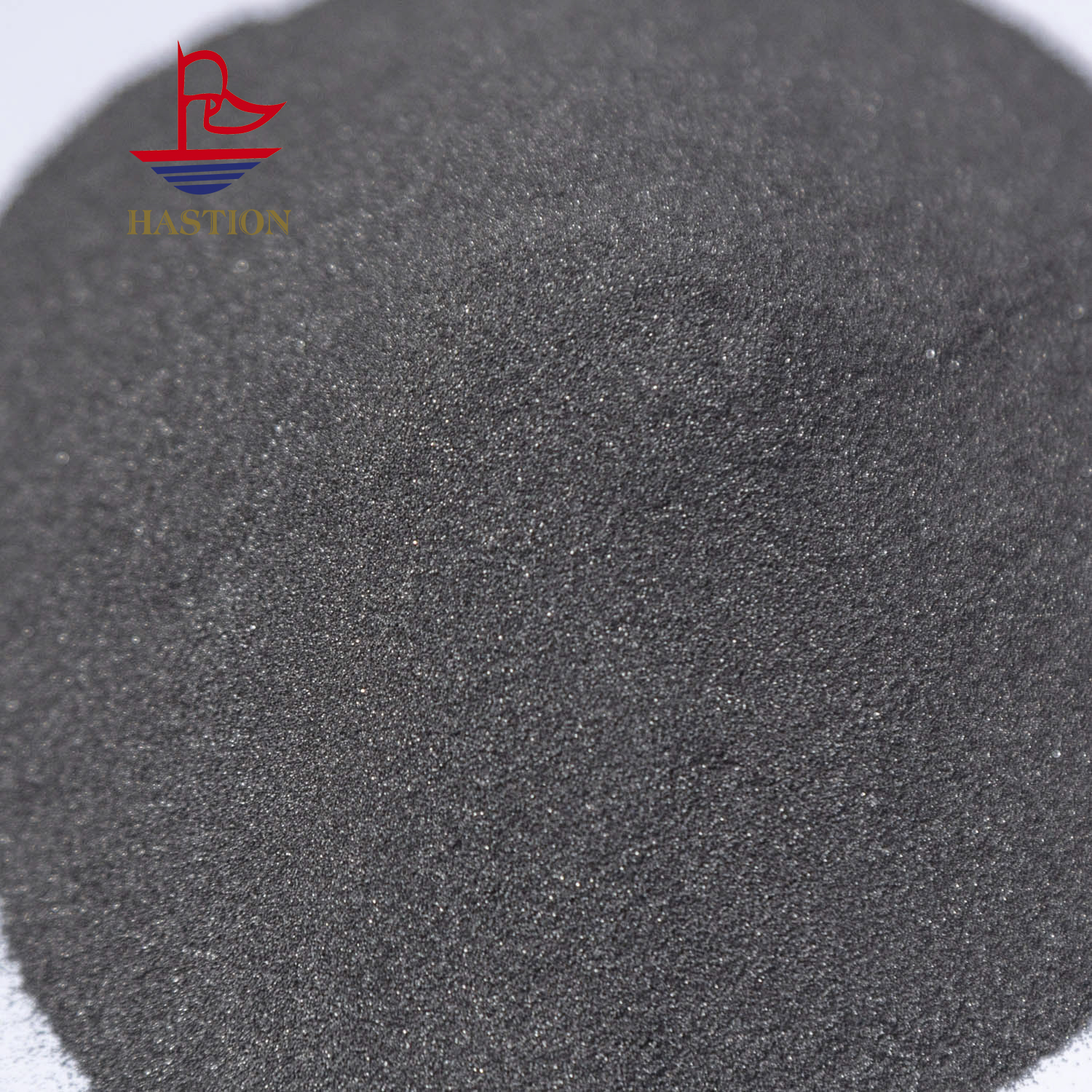

Supply of titanium carbide alloy bar tool blanks

The length of this round bar can be customized according to specific requirements, ranging from 100 mm to 1000 mm. It is amenable to secondary processing techniques such as precision grinding and wire cutting, enabling the production of components with complex geometries. Although its initial cost is higher than that of conventional cemented carbide, a comprehensive evaluation of service life and processing efficiency reveals a lower unit production techniques such as precision grinding and wire cutting, enabling the production of components with complex geometries. Although its initial cost is higher than that of conventional cemented carbide, a comprehensive evaluation of service life and processing efficiency reveals a lower unit cost. In the gear manufacturing industry, hobs fabricated from this material ensure gear tooth surface accuracy of grade 6 or higher, meeting the stringent requirements of high-performance mechanical transmission systems. Titanium carbide-based hard alloy round bars can be tailored production cost. In the gear manufacturing industry, hobs fabricated from this material ensure gear tooth surface accuracy of grade 6 or higher, meeting the stringent requirements of high-performance mechanical transmission systems. Titanium carbide hard alloy round bars can be tailored to exhibit different mechanical properties by adjusting the titanium carbide content (typically between 70% and 90%) and the binder proportion. Higher titanium carbide content enhances wear resistance, making it suitable for rough machining applications, while an increased binder to exhibit different mechanical properties by adjusting the titanium carbide content (typically between 70% and 90%) and the binder proportion. Higher titanium carbide content enhances wear resistance, making it suitable for rough machining applications, while an increased binder ratio improves toughness, rendering it ideal for precision finishing operations. With a density of only 6.5 g/cm³, it is approximately 20% lighter than tungsten carbide rods of comparable dimensions, which makes it particularly suitable for the ratio improves toughness, rendering it ideal for precision machining. With a density of only 6.5 g/cm³—approximately 20% lower than that of equivalent tungsten carbide rods—it is well suited for the manufacture fabrication of lightweight cutting tools. In the 3C electronics industry, it is widely employed in machining precision components such as smart frames and laptop housings, ensuring scratch-free surfaces and minimal dimensional deviations.

Other supplier products

供应产品

Same products