Titanium carbide rods - precision parts

The manufacturing process for this titanium carbide (TiC) round bar adheres to stringent quality control protocols. Starting from the raw material stage—where titanium carbide powder must meet a minimum purity of 99.5%—through to the sintering phase, which is precisely maintained at approximately 1500 °C, each processing parameter is rigorously controlled to ensure consistent microstructural integrity and mechanical performance. The resulting product exhibits exceptional dimensional stability: its coefficient of thermal expansion (CTE) remains at 6 × 10⁻⁶ /°C over a broad operational temperature range (−50 °C to 300 °C), substantially lower than that of conventional metallic alloys. This low CTE enables high-precision applications—such as metrology-grade tooling—under varying thermal conditions. In automotive die manufacturing, TiC-based wear-resistant inserts demonstrate outstanding resistance to high-pressure, long-duration abrasive wear, thereby significantly extending mold service life. Furthermore, with advances in additive manufacturing, TiC round bars have been successfully processed into spherical, flowable powders suitable for laser powder bed fusion (LPBF). Parts fabricated via this route achieve >99.5% of theoretical density and mechanical properties comparable to those of conventionally sintered counterparts. In photovoltaic manufacturing, TiC cutting tools are employed for precision dicing of silicon wafers, enabling thickness tolerances within ±1 μm and contributing directly to enhanced solar cell conversion efficiency. Owing to these multifaceted functional advantages, titanium carbide has become a critical enabling material in high-end precision manufacturing.

在线联系供应商

Other supplier products

| Titanium carbide rods by vacuum sintering process | Titanium carbide alloy round bar is a high-performance material made of titanium carbide (TiC) as a base, by adding metal or ceramic reinforcing ph... | |

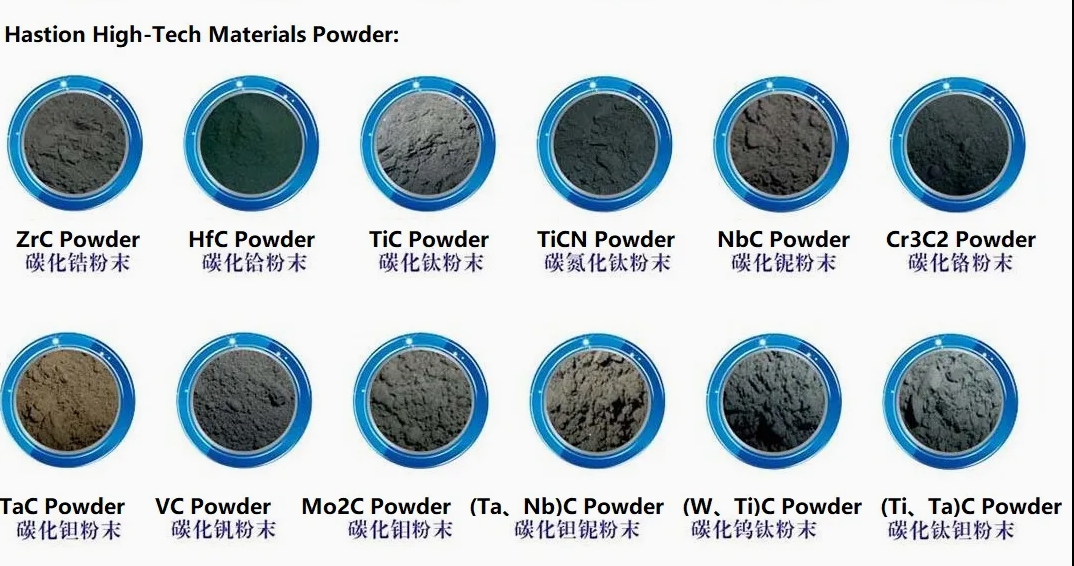

| Chromium carbide powder with outstanding forming effect | Chromium carbide powder is a grayish-black powder with a melting point of approximately 1890℃ and a Mohs hardness of 8.5. It features excellent wea... | |

| Support particle size, purity and precise control of chromium carbide powder | Chromium carbide powder is often irregular grayish-black particles with a particle size of 10-40μm, a purity of ≥98%, and a free carbon conte... | |

| Energy saving 30% + titanium carbide guide wheel | Titanium carbide guide wheel is made of high hardness titanium carbide material, with excellent wear resistance, high temperature resistance and ... | |

| Titanium carbide hard alloy round bars with excellent anti-chipping performance | Hard alloy titanium carbide round rods can be tailored into products with varying properties by adjusting the titanium carbide content (typically r... |

Same products

| 99.5% high-purity chromium carbide powder | 卖方: 株洲华斯盛高科材料有限公司 | Chromium carbide powder has excellent wetting properties and is firmly bonded to metal substrates... | |

| Carbonitride powder for plastic modification | 卖方: 株洲华斯盛高科材料有限公司 | The particle morphology of this powder can be controlled, and it can be made into spherical, near... | |

| Titanium carbide hard alloy drive wheel accessory | 卖方: 株洲华斯盛高科材料有限公司 | This guide wheel is customizable with various groove geometries—including V-shaped, U-shape... | |

| Industrial titanium carbide alloy drive wheels | 卖方: 株洲华斯盛高科材料有限公司 | This guide wheel can be customized with various slot shapes according to the specifications of wi... | |

| Wear-resistant steel-bonded hard alloy round bar | 卖方: 株洲华斯盛高科材料有限公司 | Titanium carbide (TiC)-based cemented carbide round rods exhibit exceptional electrical conductiv... |