碳化硅

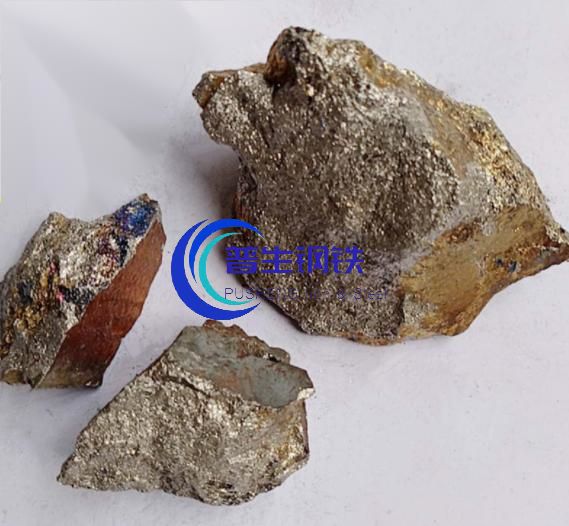

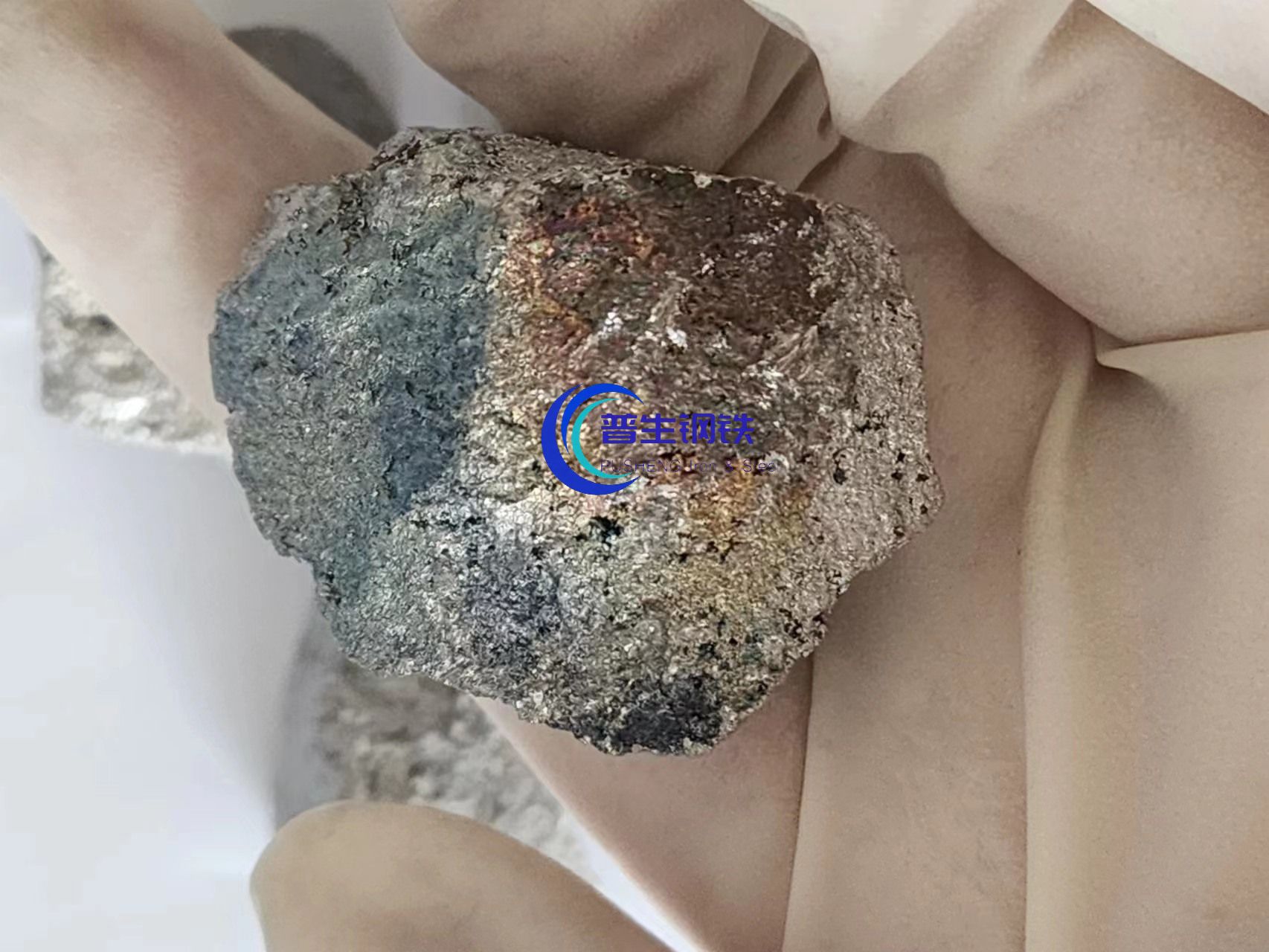

Specifications:FeMn60Si14/ FeMn65Si17

Shape: lumps

Usage:Steelmaking

Particle size:10-70mm

Packaging:ton/ Bags

| Specifications | Content(%) | Particle size(mm) |

| FeMn60Si14 | Si≥14,Mn≥60,C≤2.5,P≤0.3,S≤0.05 | 10-70 |

| FeMn65Si17 | Si≥17,Mn≥65,C≤2.5,P≤0.3,S≤0.05 | 10-70 |

Manganese-silicon alloy is an alloy composed of manganese, silicon, iron and a small amount of carbon and other elements. Manganese-silicon alloy is a composite deoxidizer commonly used in steelmaking, and a reducing agent for the production of medium and low carbon ferromanganese and the production of metal manganese by electrothermal silicon method.Silicon manganese CIF price Hs code 2849200000

Manganese and silicon are the main alloying elements used in carbon steel. Manganese is one of the most important deoxidizers in the steelmaking process. Almost all steel grades need to be deoxidized with manganese, because the oxides generated when deoxidized with manganese have a low melting point and are easy to float; manganese can also increase the silicon and the deoxidation effect of strong deoxidizers such as aluminum. All industrial steel needs to add a small amount of manganese as a desulfurizer, so that the steel can be hot rolled, forged and other processes without breaking. Manganese is also the most important alloying element in various steel grades, and 15% is also added to alloy steel. above manganese to increase the structural strength of the steel. Silicon is the most important alloying element after manganese in pig iron and carbon steel. In steel production, silicon is mainly used as a deoxidizer for molten metals, or as an alloying additive to increase strength and improve properties of steel. Silicon is also an effective stone-grinding medium, which turns carbon in cast iron into free stone-grinding carbon. Silicon can be added to standard gray cast iron and ductile iron up to 4%. A large amount of manganese and silicon are added to the molten steel in the form of ferroalloys: manganese silicon, ferromanganese, and ferrosilicon.

The raw materials for the production of manganese-silicon alloys are manganese ore, manganese-rich slag, silica, coke, dolomite (or limestone), and fluorite. One manganese ore or a mixture of several manganese ores (including manganese-rich slag) can be used to produce manganese-silicon alloys. Since manganese-silicon alloy requires lower iron and phosphorus content than high-carbon ferromanganese, manganese ore for smelting manganese-silicon alloy is required to have higher manganese-iron ratio and manganese-phosphorus ratio. The higher the manganese content of the manganese ore used, the better the indicators.

在线联系供应商

Other supplier products

| 石墨电极 | Graphite electrodes (1) For electric arc steelmaking furnace Electric furnace steelmaking is a major user of graphite electrodes. my country's el... | |

| Milled & Atomised Ferro Silicon 15% | Milled & Atomised Ferro Silicon 15%, used as heavy medium in mineral processing industry, such as: waste aluminum separation, gold ore, diamond... | |

| FeSi15 powder | Low ferrosilicon15% powder contain a small amount of silicon, It is made by electric furnace smelting after grinding process in the screening techn... | |

| 碳化硅 | Shape: briquetteUsage:SteelmakingParticle size:10-100mm or acording to your needsPackaging:ton/ Bags Component% SiC F.C ... | |

| Silicon carbon ball | Specifications:Si60C15/ Si65C18Shape: ball or blockUsage:SteelmakingParticle size:50mm or CustomizedPackaging:ton/ Bags Advantages of silicon carb... |

Same products

| 钛铁30/70 | 卖方: 内蒙古普生钢铁有限公司 | 内蒙古普生钢铁常年提供低钛高钛铁 | |

| 中国供应锰锭 | 卖方: 内蒙古普生钢铁有限公司 | 内蒙古普生钢铁长期供应电解锰, 锰锭 | |

| 内蒙古普生提供得电解锰片 | 卖方: 内蒙古普生钢铁有限公司 | 内蒙古普生提供得电解锰片 | |

| 钼铁60 | 卖方: 内蒙古普生钢铁有限公司 | 内蒙古普生钢铁有限公司常年供应钼铁, 钼铁是一种钢材冶炼添加剂 | |

| Ferro Silicon 75 Chinese High Quality Factory Ferrosilicon | 卖方: 内蒙古普生钢铁有限公司 | 内蒙古普生钢铁长期供应各种型号硅铁 |