How to repair iron casting defects?

How to repair iron casting defects?

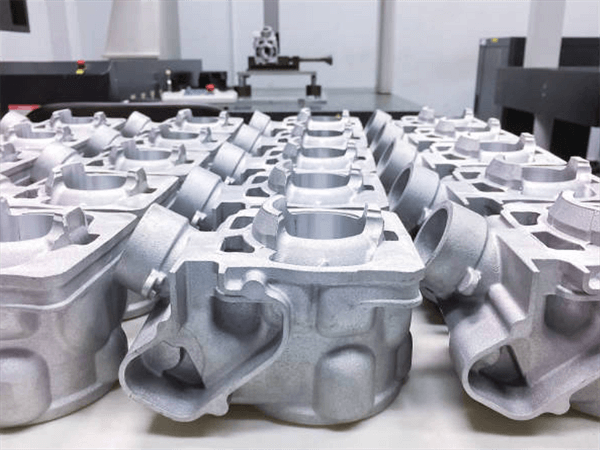

shares that defects such as porosity, pinholes, slag inclusion, cracks and pits often occur in iron castings due to various factors. Common repair equipment for argon arc welding machine, resistance welding machine, cold welding machine. Casting defects with low quality and appearance requirements can be remedied by high heating and fast welding machines such as argon arc welding machines. However, in the field of defect repair of precision iron castings, due to the large influence of argon welding heat, the repair may cause secondary defects such as casting deformation, hardness reduction, sand hole, local annealing, cracking, pinhole, wear, scratch, undercut, or insufficient binding force and internal stress damage. Cold welding machine just to overcome the above shortcomings, its advantages are mainly reflected in the small heat affected area, casting without preheating, cold welding repair at room temperature, so no deformation, undercut and residual stress, no local annealing, does not change the metal structure of the casting state. Therefore, cold welding machine is suitable for precision casting surface defect repair. Cold welding welding repair in the range of 1.5 1.2 mm Φ Φ weld points repeatedly melting process of accumulation, in the process of large area of defect repair, repair efficiency is the only factor to restrict its wide application. For large defects, the composite application of traditional welding repair technology and casting defect repair machine is recommended. But sometimes we don't have a lot of defects, there would be no need to invest more costs, we can use some repairing adhesive repair good, convenient and simple, iron material, for example, we can use (strength element into) JS902 mending, can in the later use to burn, so can save cost for our factory, casting factory, let us get more money to improve the quality of the product itself, for the users to create more wealth.

Welcome to purchase our!

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures and iron parts for clients all over the world and in different industries such as , patio furniture & company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please .

MoreProductsPlease .

在线联系供应商

Other supplier products

| [Aluminu [Aluminum Casting for sale]Complex aluminum casting process | [Aluminu [Aluminum Casting for sale]Complex aluminum casting process Complex aluminum casting such as, it is a new technology, which is based on el... | |

| Garden Decoration, Garden Decoration Aluminum Casting, Cast Aluminum Garden Decoration, Garden Decoration Casting Design | Garden Decoration,Garden Decoration Aluminum Casting,Cast Aluminum Garden Decoration, Garden Decoration Casting Design ALUMINUMCASTING ITEM No: Gar... | |

| Aluminum Casting Fence, CAST ALUMINUM FENCE, Aluminum Fence Casting | Aluminum Casting Fence,CAST ALUMINUMFENCE,Aluminum Fence Casting,Garden Fence Casting Foundry,Park Fence Casting Foundry ALUMINUMCASTING ITEM No:Al... | |

| Processing procedures and sand cleaning methods for aluminum castings | Processing procedures and sand cleaning methods for aluminum castings shares that aluminum casting is a kind of pressure casting parts, is the use ... | |

| The main defect of aluminum alloy casting is crack | The main defect of aluminum alloy casting is crack formed at a high temperature. It is easy to occur when the casting volume shrinkage is large an... |

Same products

| TH300 Portable Lee Hardness Tester | 卖方: Beijing Lanetech Square Co., Ltd. | This device is a split-type measurement tool designed for rapid, non-destructive, and highly accu... | |

| Custom Gravity Cast Service | 卖方: 新航金属制品有限公司 | 探索重力铸造与其他铸造方法之间的差异,以确定适合您项目的最佳选择。 材料范围:ADC12、AZ91D、C83600、不锈钢 304、Casr 铁 尺寸范围:最小 15 毫米,最大 250... | |

| Metal Injection Molding Service for MIM Parts Manufacturing | 卖方: 新航金属制品有限公司 | Neway is a top-notch metal injection molding service provider for custom MIM parts. Get your ... | |

| 2024年第二十四届广州国际压铸、铸造及工业炉展 | 卖方: 广州巨浪展览策划有限公司 | 2024广州巨浪国际金属暨冶金工业展览会 2024年第二十四届广州国际压铸、铸造及工业炉展 邀 请 函 ... | |

| Hydraulic Steering Control Units | 卖方: Hebei Golden-hammer forgings co., ltd | The hydraulic steering gear is a hydraulic power steering type between the steering wheel and the... |

![[Aluminu [Aluminum Casting for sale]Complex aluminum casting process](/images/products/products_796746_8c91c9037d42dfeab4e687d7dfaeb636.jpeg)