Causes die casting production die damage

Causes die casting production die damage

In the process ofproduction of aluminum casting, the causes of easy damage are:

The cutting stress produced in finishing machining such as turning, milling and planing can be eliminated by intermediate annealing. When hardening steel is ground, grinding stress is generated, friction heat is generated during grinding, softening layer and decarburization layer are produced, which reduce thermal fatigue strength and easily lead to thermal crack and early crack. After fine grinding, h13 steel can be heated to 510-570℃ and stress-relieving annealing can be carried out every 25mm insulation hour.

Edm produces stress. There is a white layer of enriched electrode elements and dielectric elements on the surface of the die, which is hard and brittle, and the layer itself will have cracks and stresses. The high frequency should be used in edm to minimize the white layer, which must be removed by polishing method and tempered at three tempering temperature. Quality problem of blank forging. Some molds produce only a few hundred aluminum castings before they crack, and the cracks develop quickly. It is possible that only the outside size is guaranteed during forging, and the loose defects such as dendritic crystals, inclusions of carbides, shrinkage holes and bubbles in steel products are extended and elongated along the processing method to form a streamline, which has a great influence on the final quenching deformation, cracking, brittle crack and failure tendency during use.

That's all for the sharing,and we supplyfor sale, if you have any demand for our products,just feel free to contact us.

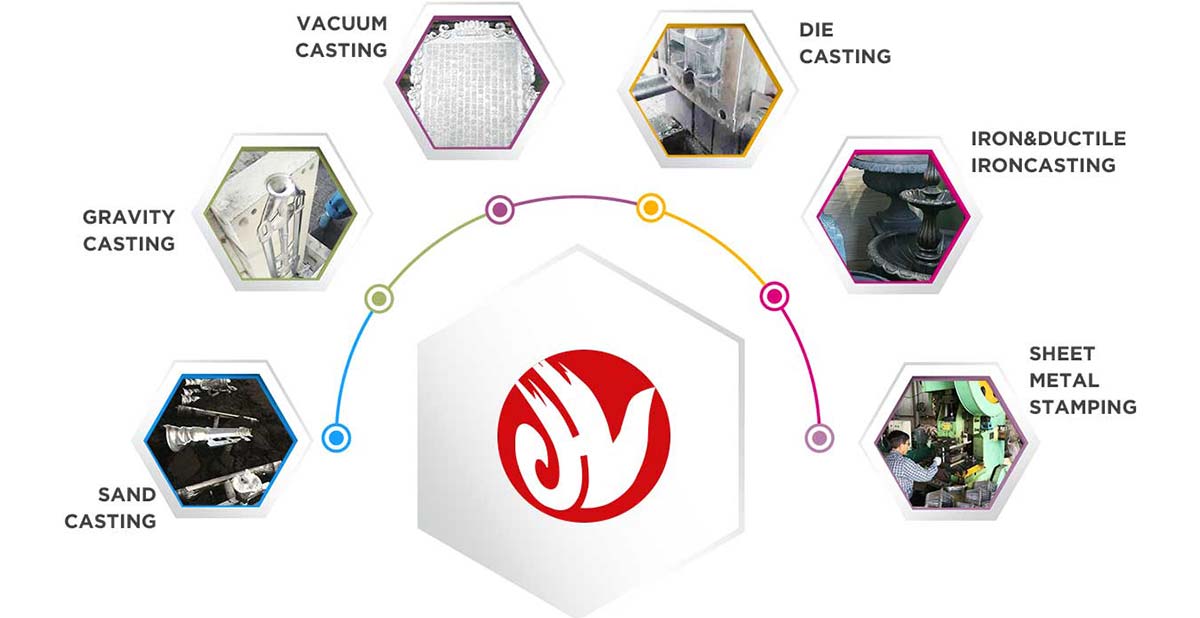

Located in Liaoning province in northeastern China, LianJiang Metals Company have specialized in aluminum and iron casting production since 1997. We are an OEM partnership that manufactures and iron parts for clients all over the world and in different industries such as , patio furniture & company.

With over 20 years of casting work experience and expertise, we offer a full range of casting processes including:sand casting,gravity casting,die-casting,vacuum casting

If you want to know more about the product, please .

MoreProductsPlease .

在线联系供应商

Other supplier products

| CASTING SOLUTIONS, Cast Aluminum and Iron Parts, Garden Decoration Cast Part | CASTING SOLUTIONS,Cast Aluminum and Iron Parts,Garden Decoration Cast Part Located in Liaoning province in northeastern China, LianJiang Metals Com... | |

| Garden Decoration, Garden Decoration Aluminum Casting, Cast Aluminum Garden Decoration | Garden Decoration,Garden Decoration Aluminum Casting,Cast Aluminum Garden Decoration, Garden Decoration Casting Design ALUMINUMCASTING ITEM No: Gar... | |

| CASTING SOLUTIONS, Cast Aluminum and Iron Parts, Garden Decoration Cast Part | CASTING SOLUTIONS,Cast Aluminum and Iron Parts,Garden Decoration Cast Part Located in Liaoning province in northeastern China, LianJiang Metals Com... | |

| [Aluminum Casting for sale]Characteristics and definition of aluminum alloy die castings | [Aluminum Casting for sale]Characteristics and definition of aluminum alloy die castings Characteristics and definition of aluminum alloy die casti... | |

| The main defect of aluminum alloy casting is crack | The main defect of aluminum alloy casting is crack formed at a high temperature. It is easy to occur when the casting volume shrinkage is large an... |

Same products

| Cast iron service | 卖方: 山西海洛斯铸锻件有限公司 | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | 卖方: 山西海洛斯铸锻件有限公司 | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | 卖方: 新航金属制品有限公司 | 铬镍铁合金定向铸造服务:高性能应用的高精度 因科镍合金以其卓越的强度和耐高温性而闻名,是需要能够在极端条件下运行的部件的行业中不可或缺的材料。航空航天、发电和石化等行业要求材料不仅能承受高温,而... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | 卖方: 新航金属制品有限公司 | 因科镍合金粉末冶金涡轮盘服务:高性能部件的先进制造 铬镍铁合金粉末冶金 (PM) 涡轮盘制造对于为航空航天、发电以及石油和天然气等需要最高可靠性和强度的行业生产高性能部件至关重要。涡轮盘是喷气发... | |

| CMSX Series Single Crystal Casting Service | 卖方: 新航金属制品有限公司 | CMSX系列单晶铸造服务简介 CMSX 系列是一系列先进的单晶高温合金材料,专为高温应用而设计,特别是在航空航天和发电行业。这些合金以其在极端条件下的卓越性能而闻名,例如燃气轮机、喷气发动机和其... |

![[Aluminum Casting for sale]Characteristics and definition of aluminum alloy die castings](/images/products/products_796739_3ba6b419c5c3d0556fcbcc706954e072.jpeg)