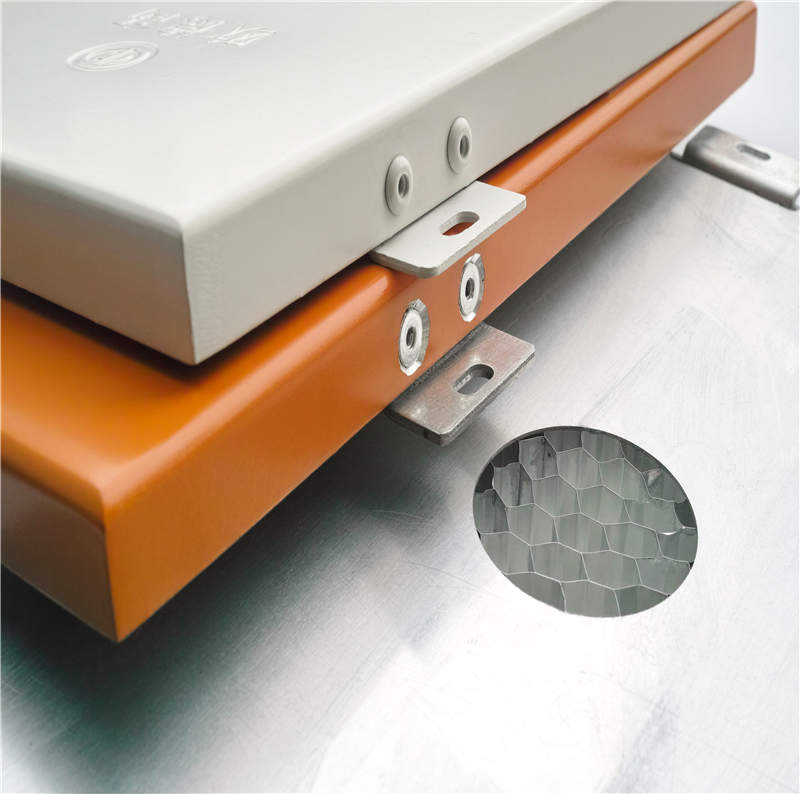

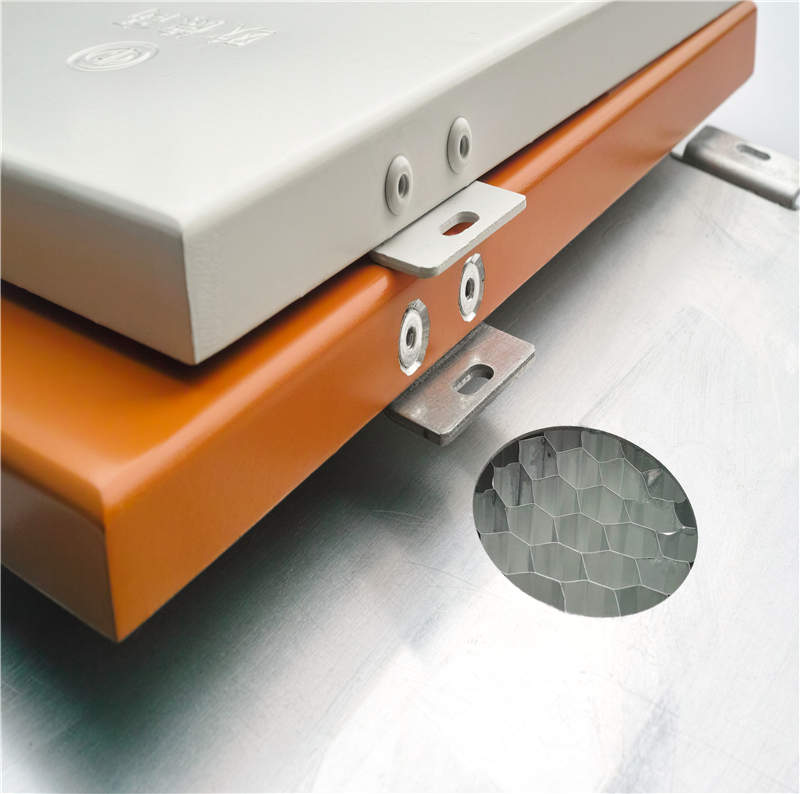

1100 Aluminum Honeycomb Panel

Manufacturers to undertake customized public decoration waterproof aluminum

Product Feature and Application of the Aluminum Honeycomb Core Sandwich Panel

Honeycomb structures are natural or man-made structures that have the geometry of a honeycomb to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells formed between thin vertical walls. The cells are often columnar andhexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

Man-made honeycomb structural materials are commonly made by layering a honeycomb material between two thin layers that provide strength in tension. This forms a plate-like assembly. Honeycomb materials are widely used where flat or slightly curved surfaces are needed and their high Specific strength is valuable. They are widely used in the aerospace industry for this reason, and honeycomb materials in aluminum, fiberglass and advanced composite materials have been featured in aircraft and rockets since the 1950s. They can also be found in many other fields, from packaging materials in the form of paper-based honeycomb cardboard, to sporting goods like skis and snowboards.

|

ITEM |

DETAILS |

|

Product Name |

Aluminum Honeycomb Panel |

|

Aluminum Alloy |

1100,3003 |

|

Panel thickness |

|

|

Max size |

2000*7000mm |

|

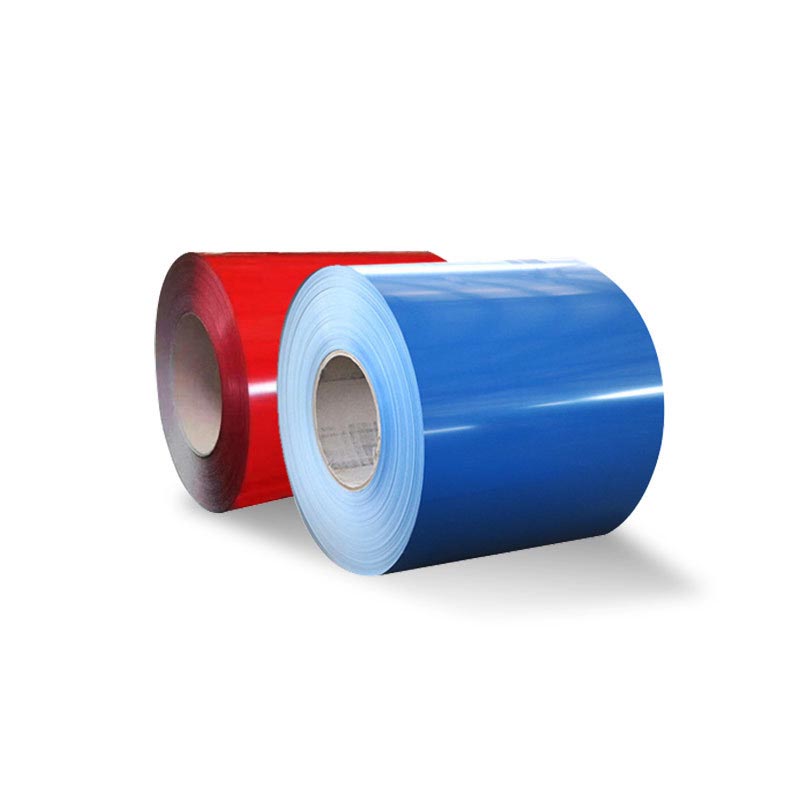

Surface treatment |

PVDF 2/3/4 Layer coating |

|

Powder coating |

|

|

Wood grain (wood grain paper /Therminal transfer printing / wood grain painting) |

|

|

Stone grain (stone grain painting / Therminal transfer) |

|

|

Color |

RAL color, Pantone color |

|

Shape |

Flat, cambered, double curved, triple curved, spherical, customized shaped. |

|

Warranty |

Max 25 years guarantee for ideal application evvironment |

|

Packaging |

Carton package |

|

Leadtime |

15-20 days after receiving the deposit and confirm the details |

Technical Details of Aluminum Honeycomb Core Sandwich Panel

Technical Details of

|

Thickness |

20mm |

25mm |

|

Aluminum surface plate |

||

|

Aluminum reverse plate |

||

|

Weight (kg/m2) |

||

|

Mechanical properties of composite panels and panel |

||

|

Moment of inertia I (cm4) |

||

|

Section modulus W(cm3) |

19 |

19 |

|

Composite plate stiffness E.I(KN cm2) |

139000 |

139000 |

|

Aluminum panel |

AA5754A(ALMg3) |

|

|

Modulus of elasticity (N/mm2) |

70000 |

|

|

Panel tensile strength (N/mm2) |

Rm≥220 |

|

|

Elongation (EN485~2:1194) |

A50≥8 |

|

|

Aluminum linear heat expansion |

||

|

Surface decoration Layer |

PVDF Spray and bake paint |

|

|

Gloss (initial value) |

30-40% |

|

|

Pencil hardness |

HB-F |

|

|

Honeycomb core |

||

|

Cellular size |

1/4''(6.3mm) |

|

|

Lead material capacity |

About 80kg/m3 |

|

|

The compressive strength (MIL-STD-401) |

4N/mm2 |

|

|

Acoustic performance |

||

|

Absorption coefficient AS |

||

|

Sound insulation coefficient (According to ISO717-RW) |

23 |

25 |

|

The thermal performance |

||

|

Coefficient of thermal conductivity (w/m2k) |

||

|

Thermal resistance R(1/m) (m/m2k) |

||

|

Heat transfer coefficient U(K) (M/M2K) |

||

a. Light weight, Good rigidity, high strength and safety

Theweight is only 1/70 of that for bricks and 1/3 of that for stainless steel.

b. Fireproofing Properties

Tested by National Research Center of Testing Techniques For Building Materials, the properties of meet the requirement of non-flammable materials. According to GB-8624-1997 Standard, the aluminum honeycomb panels fireproofing grade is GB-8624-B1 Grade.

c. Super Flatness and Rigidity

The special hexagonal structure of aluminum honeycomb panel is composed of many dense hexagonal cells and these cells are similar to many I shapes, which averagely take the pressure from the panel surface. The property assures the high compression strength and super flatness over a large area.

d. Sound Insulating, Heat Insulation, Heat Preservation

Between the two skins are divided into many closed and independent cells, which to a great extent limit the transmission of sound wave and heat.

e. Moisture resistance , Corrosion Resistant

The surface skins are manufactured through roller-coating techniques, thus anti-anodizing, color-stable and no going moldy and deforming. According to testing, the aluminum honeycomb panel remains intact after immersed in 2% HCL solution or in saturated Ca(OH)2 Solution for 24 hours.

f.Environmentally Friendly

High quality aluminum single solid panel for ceiling could be recycled absolutely which is different with other material. And aluminum honeycomb panels does not emit any hazardous gas and easy to be cleaned and also easily recyclable.

Here is Shunde Goodwill Metal Work which produces Aluminum Wall Cladding, Aluminum Solid Panel, Aluminum Honeycomb Panel.We are professional .

在线联系供应商

Other supplier products

| Aluminum Ceiling Tile | Decorative aluminum waterproof ceiling tileperforated metal sheet for Commercial Building Aluminum Ceiling Tile Product Description ITEM DETA... | |

| 1100 Aluminum Honeycomb Panel | Manufacturers to undertake customized public decoration waterproof aluminum honeycomb partition panel Product Feature and Application of the Alumi... | |

| Fashionable Metal Ceiling Serie Aluminum Baffle Ceiling Cladding Design For Interior or exterior decoration | Fashionable Metal Ceiling Serie Aluminum Baffle Ceiling Cladding Design For Interior or exterior decoration Aluminum baffle ceiling is kind of v... | |

| Diamond shaped perforated pattern metal plate mesh steel panels for architeture | Diamond shaped perforated pattern metal plate mesh steel panelsfor architeture Aluminum Metal Mesh Panel Clip in square aluminum ceiling. variety... | |

| Metal Ceiling Strip Aluminum Suspended Decorative False Ceiling Design With | Metal Ceiling Strip Aluminum Suspended Decorative False Ceiling Design With Building Materials is kind of visible curtain type ceiling. The visu... |

Same products

| 定制1100/3003/3105/5052/8011型PE和PVDF彩色涂层铝卷,适用于屋顶、卷帘门和汽车应用。 | 卖方: Henan Hongchang Aluminum Co., Ltd. | 产品描述 彩色涂层铝卷(预涂铝卷)采用优质铝合金卷材,经脱脂、化学处理、涂装和高温固化等工艺生产而成。涂层均匀,附着力强,显著提升装饰美观度的同时,提高了耐腐蚀性、耐候性和使用寿命。 我们提... | |

| 1050/1060/3003/5052/5083 铝制圆盘,适用于炊具和交通标志 | 卖方: Henan Hongchang Aluminum Co., Ltd. | 出售1050/1060/3003/5052/5083铝圆片,用于炊具和交通标志 Tag:炊具铝圆片,交通标志铝圆片 铝圆片(Aluminum Discs / Aluminum Cir... | |

| 出售3003 O / H18不粘铝制圆片,适用于炊具,工厂价 | 卖方: Henan Hongchang Aluminum Co., Ltd. | 3003不粘铝圆片是一种采用3003铝合金制成的高品质铝盘产品。它经过轧制、拉拔、冲压和退火等工艺生产。作为铝锰(Al-Mn)系列铝合金的一员,3003铝合金具有优异的耐腐蚀性、良好的延展性、出... | |

| Aluminum Extrusion 6063 Scrap Supplier, Aluminum Profile Scrap Supplier, Aluminum 1050 Scrap Supplier, Aluminum 6061 Scrap For Sale, Aluminum Foil Scrap Supplier, Scrap 6063 Aluminum Supplier, Aluminu | 卖方: Best Link Trading Co., Ltd | Best Link Scrap Inc. 是一家值得信赖的全球优质铝挤压废料供应商,我们专注于备受追捧的 6063 和 6061 牌号。我们的使命是为回收商、制造商和挤压生产商提供可靠、可持续且... | |

| Painted Aluminum for PP/ROPP Cap | 卖方: Zhengzhou Haomei Industrial Co., Ltd. | It is applicable for cosmetics, yogurt caps, pharmaceutical bottle caps, milk tear-off caps, anti... |