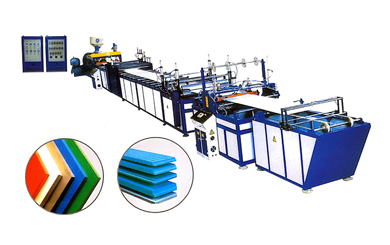

Plastic Sheet Extrusion Line

Plastic extruder adopts several extruders and is mainly applied to manufacture multi-layer plastic sheet of PP, HIPS, PE and other materials meeting the requirement of different applications. These plastic sheets can be used to make plastic containers, plastic trays, plastic cup, plastic covers with the help of the thermoforming machine, which are widely applied to printing, packaging, hardware packaging and so on.

Plastic Sheet Extrusion LineList

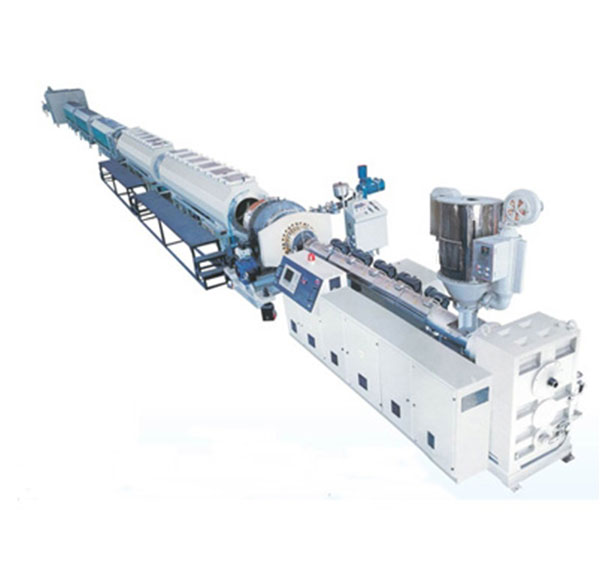

XPS Foamed Board Extrusion Line

Melt Blown Fabric Production Line

PE Foamed Sheet/Film Production Line

PVC Crust Foamed Plate Production Line

EPS Foamed Sheet ( KT Plate ) Production Line

PP Hollow Plastic Building Board Production Line

EVA Waterproof Seal Strips Production Line

PC, PP, PE Hollow Profile Board Production Equipment

Sheet Extrusion Production Line Construction

The sheet extrusion lineconsists of an extruder (single-screw extruder or twin-screw extruder) equipped with a screen changer and a gear pump, followed by a static mixer (sometimes it is sent to the co-extrusion feed head first, and then to the co-extrusion head) . Add or other multiple extrusion units as described above). Send into the flat mold.

Then, cool the paper through 3 (or more) roll paper stacks (paper pickers) and control the temperature, pressure and nip.

Finally, cut the paper into a certain length, roll it into a roll, or perform the second step online.

Feature Of Plastic Sheet ExtrusionLine

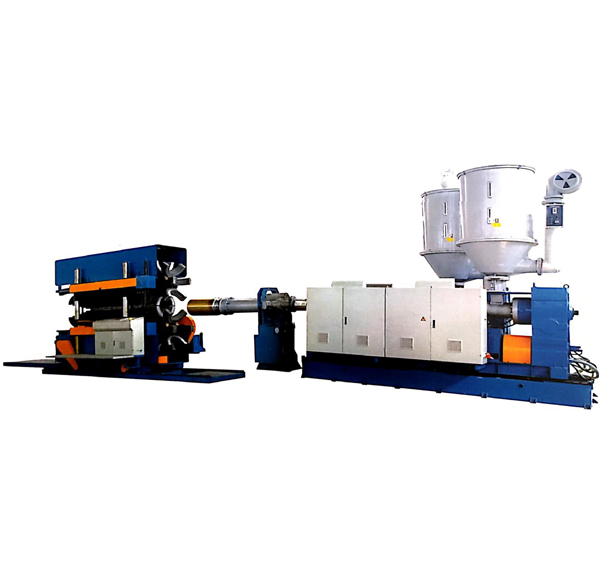

The single screw plastic extruder in the manufacturing line adopts new type of screw structure featured as stable feeding and uniform fusion mixing, which can reduce energy consumption and increase production output.

The plastic extruder adopts directly connection between motor and reduction gears, which can improve transmission efficiency and reduce speed fluctuation ensuring the stability of extrusion.

The extruder is designed with the melt dosing pump and it can cooperate with precise multi-layer distributor. The flow proportion and blade clearance ratio are all adjustable, which can lead to a more uniform plastic sheet layer.

The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.

Qingdao Kailite plastic machinery Co., LTD. is aprofessional plastic sheet extrusion companies, we provide sheet extrusion machine, sheet extruder machine, plastic sheet extrusion machine, plastic sheet extrusion line for sale, plastic extrusionand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| PP-R/PP/PE Plastic Tube Production Line | That production line design special, adoption BM separate type efficiently the pole of automating the degree is high, operation convenience, contin... | |

| PE PVC Single / Double wall corrugation pipe production line | lClose type corrugator and vacuum for forming. lForming module is moving in a tunnel. lForming tunnel is clod by water. lForming module is made of ... | |

| PE/PVC Large Diameter Double Wall Corrugated Pipe Production Line | The Parameter of PE/PVC Large Diameter Double Wall Corrugated Pipe Production Line Model JG-SEG-630 JG-SEG-800 Raw material P... | |

| HDPE Water And Gas Pipe Production Line | Features & Advantages: The Large Diameter HDPE/MDPE Pipe Extrusion Line research & developed by Jwell Machinery Co., features of unique str... | |

| PVC Pipe Production Line | PVC pipe production line is mainly used in the manufacture of the plastic PVC pipe with various tube diameters and wall thickness in the aspects su... |

Same products

| Iron Single Adjustable Cafe Rod Set | 卖方: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Competitive Price OEM Waterproof Nylon Injection Molding Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| Wholesale Plastic Injection Insert Molding Custom Plastic Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Pla... | |

| 塑料定制品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| z中国工厂定制塑料品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... |