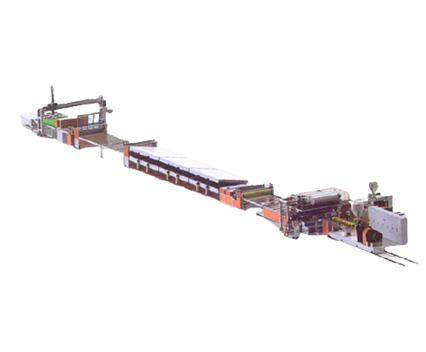

Plastic Pipe Production Line

This machine developed by Kailitecompany plastic pipe production line manufacturersis featured of unique structure, a high degree of automatic, easy operation and stable reliable continuous manufacture performance can meet all kinds of plastic pipe production needs.

How to Extrude PVC Pipe?

PVC Pipe Extrusion Process

The plastic raw materials are loaded into the hopper and then fed into the extruder machine.

The molten plastic material is moved through the extruder by rotating bolts. It is important to note that some extruders can have one or two rotating bolts.

The molten raw material flows down from the feed hopper through the feed throat and flows to the large spinning screw running in the horizontal barrel of the micro single screw extruder.

In a horizontal bucket, the molten material is filtered to ensure a uniform consistency.

The performance of the plastic material will vary according to the material it is made of. However, relative to the type of raw material passed, the raw material is processed by heating it at a specific temperature.

After processing, the molten plastic is pushed into a small opening called a mold. This allows the material to be sized or shaped to the desired final size.

The die cutting for specific plastic profiles is designed to help smooth and even flow from the cylindrical profile of the extruder to the final profile shape.

The consistency of plastic flow is essential to obtain a high-quality and reliable final product.

When the plastic is extruded from the mold, it is transported to a conveyor belt for cooling. The finished product can be cooled by air or water.

How Long do Plastic Pipes Last?

The plastic pipes extrude speed is different, by plastic extrusion, Imake a excel sheet to express the time, plastic pipe making machine can be used to produce corrugated pipes of PP/PE/PVC/EVA/PA continuously. Plastic single wall corrugated pipes have features of high temp. Resistance, corrosion and abrasion resistance, high intensity and good flexibility,etc. They are widely used in fields of auto wire harness,electric thread-passing pipe, circuit of machine tool, protective of lamps and lantern wire, tubes of air conditioner and washing machine etc.

Which Plastic Pipe is Best?

At present the high speed corrugated pe pipe production lineis gradually better and better, can produce PP PE PVC EVA PA ect material.

Single wall corrugated pipe continuously. We design new technology,replace the traditional chain forming machine. The appearance and precision of single wall corrugated pipe have improved greatly. The production line is driven by gears, and the mould runs in the track. It is equipped with an automatic lubrication system and a closed forced water cooling system to achieve high-speed production.The plastic pvc pipe making lineis different due to different material.

If you want to know more about tube extrusion and pipe making, please visit our website.

在线联系供应商

Other supplier products

| Automatic Plastic Mixer | the parameter of Automatic plastic mixer Model Motor Power(kw) Mixing Capacity(kg) Rotation speed(r/min) Mech... | |

| HDPE Corrugated Tube Production Line | The raw material of the plastic corrugation pipe is HDPE, resisting corrosive, acid and alkali, preventing the prestressing muscle from boing erode... | |

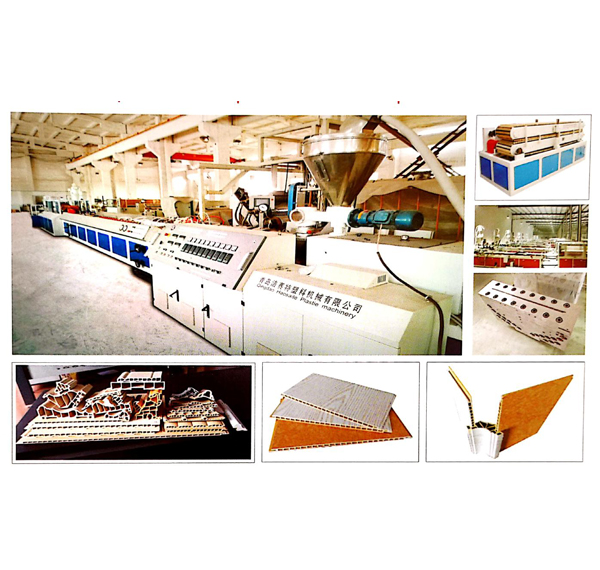

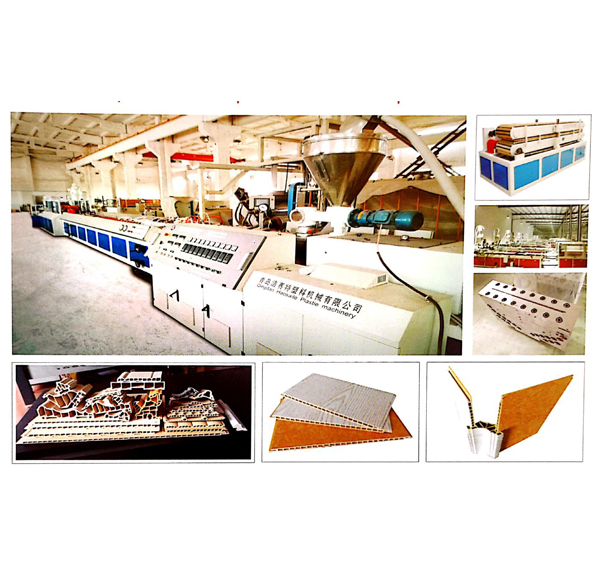

| PVC Wood-Plastics Composite Wallboard Production Line | PVC wood plastic composite wallboard is a kind of composite material which is sawdust, wood chips, such as low biomass fiber as the main raw materi... | |

| PVC Wood-Plastics Composite Wallboard Production Line | PVC wood plasticcomposite wallboard is a kind of composite material which is sawdust, wood chips, such as low biomass fiber as the main raw materia... | |

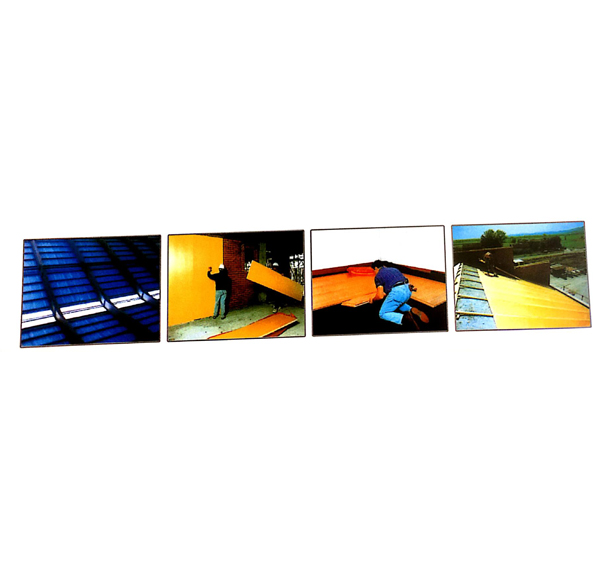

| XPS Foamed Board Extrusion Line | XPS foamed board, has a perfect close. Its density, water absorption coefficient of heat conducting and the coefficient of steam pervasion are all... |

Same products

| Iron Single Adjustable Cafe Rod Set | 卖方: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Competitive Price OEM Waterproof Nylon Injection Molding Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| Wholesale Plastic Injection Insert Molding Custom Plastic Parts | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Pla... | |

| 塑料定制品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| z中国工厂定制塑料品 | 卖方: 河北二业橡塑制品有限公司 | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... |