Auto Duct Production Line 3

Performance features of Auto Duct Production Line 3:

Auto duct production line 3 composed of a decoiler, leveler grooving unit, "V" and "square" notching unit, cutting unit, bending unit composition. The standard configuration the "V" and "square" notching unit make for TDF flange duct, there into the "square" notching unit also can be used to produce TDC flange. Bending unit can be made with the Pittsburgh match the right angle, also can be sheet metal bending into a "square" or "L" type. Greatly improve the utilization of the plate, reduce labor intensity and reduce labor. The production line electrical control part adopts full servo control; the control system has a closed-loop feedback system, Accuracy and stability were obvious improved. The maximum operating speed of 16m/min. Length tolerance is ±0.5mm; diagonal tolerance is ±0.8mm. The system can meet each shift(8 hours) production capacity of the 1000m² duct. BLKMA company specializes in manufacturing and sales of air duct line II, III, IV, V, CNC angle steel flange production line, shear, folding, machine, bender, duct zipper, spiral former, CNC plasma cutter, elbow maker, TDF flange machine, grooving machine, slip roller machine and so on. Duct production line 3 can drive blanking for the duct. Meantime, It's very suitable for diversified production like TDF/angle steel/inserted flange forming, the angle steel flange, and inserted flange can be bent into square-shaped pipe automatically. 1. Aluminum alloy suspension arm makes the machine easy to operate. 2. The built-in control cabinet reduces wiring as a whole structure and makes it easy to move. 3. The imported configuration is very stable and comfortable to use. Cnc air duct production line is a duct making line with the highest automation and highest efficiency in rectangular air duct production line machines. The airflexible duct machinemade by BLKMA company can help customers to finish all needed process from cutting sheet metal to forming the whole duct under the control of auto CNC system. Automatic CNC control system greatly improves the precision and the beauty. Auto duct production line includes auto duct line 2, auto duct line 3, auto duct line 4, linear auto duct line 5 and U shape auto duct line 5. Our company will provide customers the most suitable machines according to customers needs. Besides, we can also customize machines on the basis of your special requirement.

The basic configuration of Auto Duct Production Line 3:

One electric coil cradle(two material trays). One set leveling and beading equipment. the hydraulic angle-shearing machine with four sets of the die. The hydraulic sheet-shearing machine, hydraulic bending machine, hydraulic press machine. A set of CNC computer control system and production software. One motor

The main imported configuration of Auto Duct Production Line 3:

Beijing Huade+Hydraulic system from Taiwan. Japan Omron encoder. Japan Mitsubishi CNC system Germany Schneider electrical system.

在线联系供应商

Other supplier products

| CNC Plasma Cutting Machine | CNC Plasma Cutting Machine Performance Features: CNC plasma cutting machineis mainly for automatically lofting and cutting the deformed workpiece.... | |

| Beading Machine | Anhui BLKMAheavy industry machineryCo.,ltd. is located in the center of China's machine tool industry, Ma'anShan BoWang District Dongcheng Industri... | |

| Angle Steel Round Rolling Machine | Angle Steel Round Rolling Machine Performance Features: It's used for rounding angle steel flange and 40Cr steel with overall heat treatment makes... | |

| Beading Machine | Beading Machine Performance Feature: Line 5 beading machine and line 7 beading machine are used to make sheet metal reinforced ribs during HVAC ai... | |

| Electric Shearing Machine | BLKMAis one of the best auto duct forming machine manufacturers you can find in China, which can provide overseas spiral duct machineand service in... |

Same products

| Full automatic double end terminal crimping machine 2Pin flat wire | 卖方: 816004 | product link: Features Full automatic terminalcrimping machine, using high-tech frequency con... | |

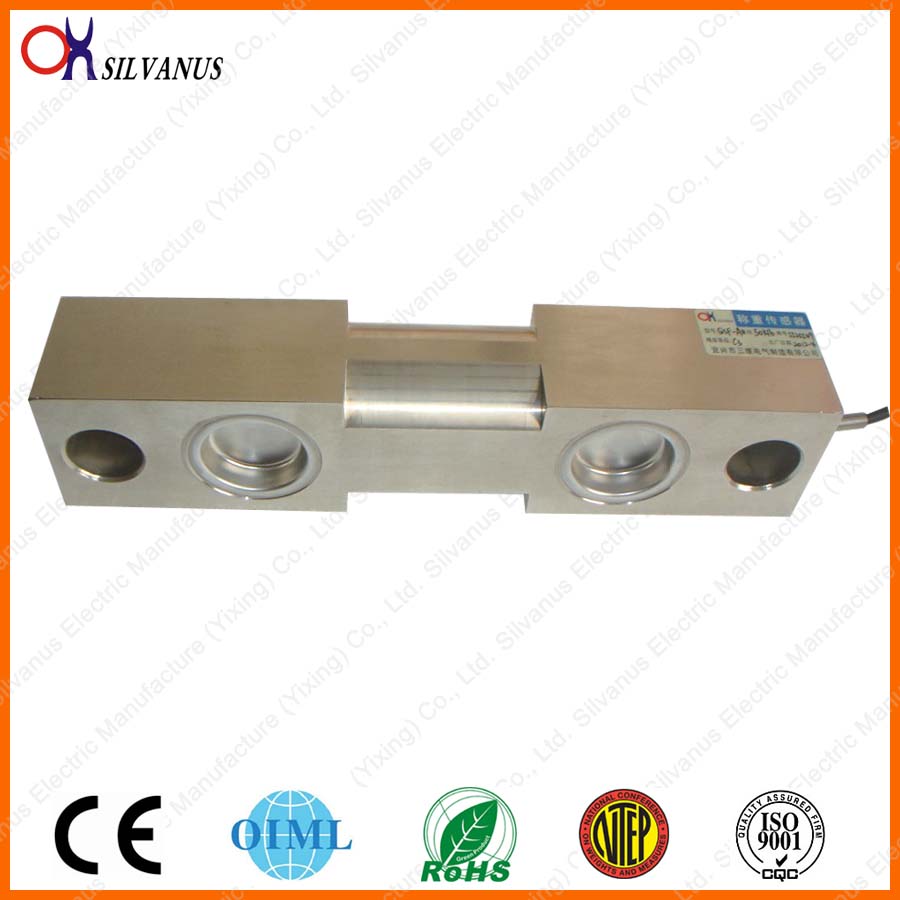

| 桥式双端剪力梁式称重秤QSF50~75klb适用于电子汽车衡 | 卖方: 宜兴市三维电气制造有限公司 | 桥式双剪力梁,独特的浮支承结构 自复位,具有良好的侧力和抗冲击性能 防潮密封,适用于恶劣环境 安装简单,使用方便,互换性好 适用于电子汽车衡、铁路衡、料斗秤及各种特殊秤。 | |

| 用于筒仓称重称重传感器1t-20t | 卖方: 宜兴市三维电气制造有限公司 | 与托利多FW称重模块完全兼容;额定载荷: 500kg ~ 20000kg;结构独特,可方便地安装在各种槽罐上;三种顶板结构(固定式、半浮动式、浮动式)可以消除槽罐因热涨冷缩带来的称量误差;支撑螺... | |

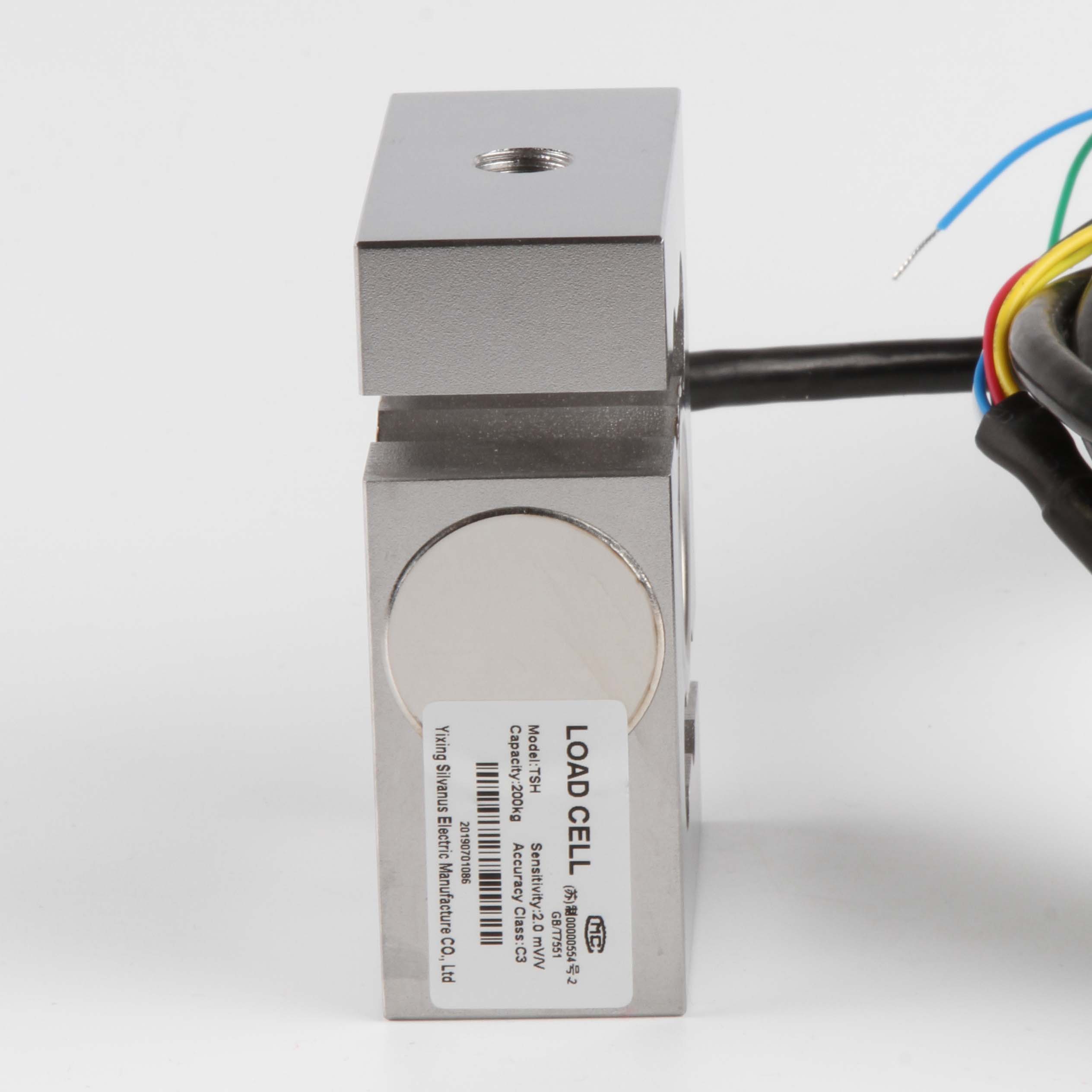

| S 类型 负载 细胞 , 张力 和 压缩 高精度合金钢200 -5000kg S型称重传感器,适用于机电秤、吊车秤、料斗秤 | 卖方: 宜兴市三维电气制造有限公司 | TSH型钢制“S”型称重传感器,承受拉、压外力均可,输出对称性好,结构紧凑、安装方便,规格齐全。可用于制造机电结合秤、吊钩秤、料斗秤及各种专用秤、工艺秤等。 | |

| 600*600 ceiling panel machine | 卖方: Foshan lesheng metal machinery co.,ltd |